Absolut Encoder

Dynapar a manufacturer of encoders absolute encoder & rotary encoder Dynapar, Northstar, and Harrowe brands for every encoder application.

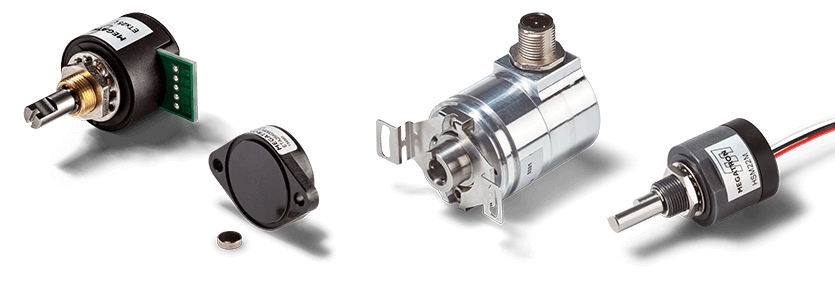

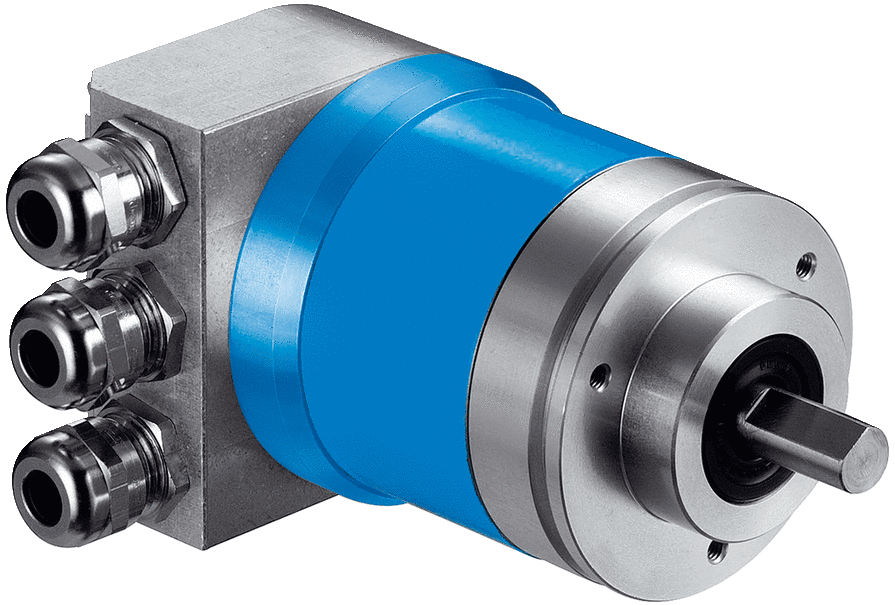

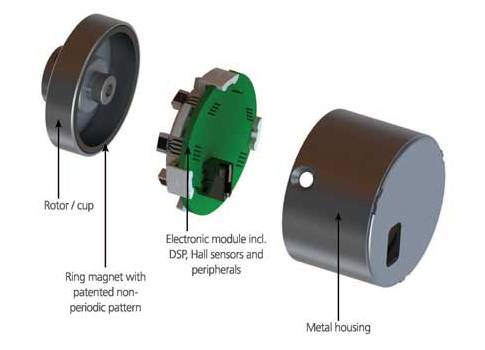

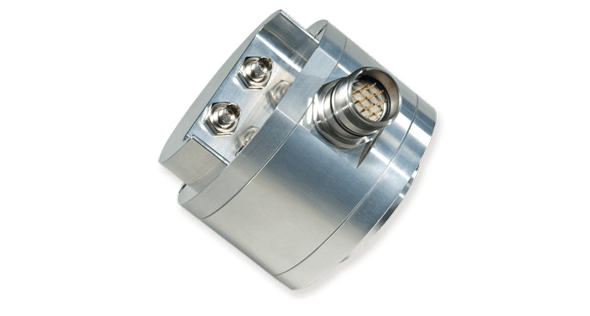

Absolut encoder. Absolute encoder WV36M/CAN Metal housing with solid shaft Magnetic, absolute multiturn rotary encoder WV36M/CAN batteryless, with CANopen or SAE J1939 interface Owing to its double ball bearing, small design and wearfree magnetic measurement method, the WV36M/CAN is also best suited for positioning jobs in mechanically demanding environments. Encoders can be either absolute or incremental Absolute encoders have a unique code for each shaft position Or in other words, every position of an absolute encoder is distinctive The absolute encoder interprets a system of coded tracks to create position information where no two positions are identical. We put a spin on things with even more interfaces and customizability In the encoder world, one size does not fit all and our diversified line of absolute encoders ensures that we have the right product for your unique applications Big, small, heavy duty, watertight, ATEX and SIL, we’ve got you covered All the major Fieldbus, Ethernet and discrete interfaces for you to choose from.

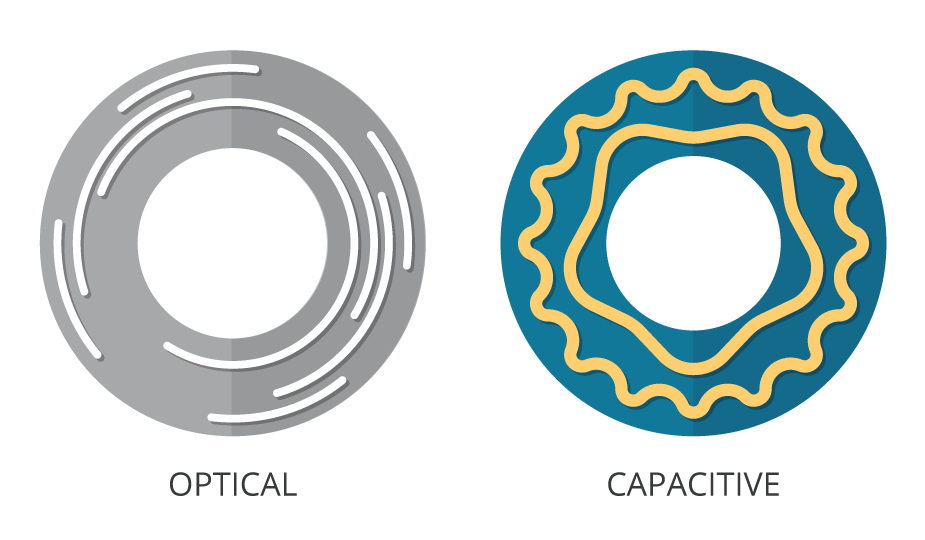

US Digital designs and manufactures absolute encoders in both optical configurations, for the highest possible resolution and accuracy, and magnetic versions for demanding environments In either case, absolute encoders report a shaft angle within a single 360degree shaft rotation without stops or gaps Unlike incremental (sometimes called "relative") encoders, absolute encoders provide true (absolute) shaft position, eliminating the need for a "home" or "zero" cycle after a supplyvoltage. Severe Mill Duty Shafted Absolute Encoder, Singleturn or Multiturn HS6A HS6A Optical Rotary Absolute Encoders, Hollow Shaft, 03"06" 815mm HS6M Mill Duty Absolute Encoder, Single or Multiturn, Fits Shafts 024"059 615mm HS40 Severe Mill Duty Magnetic Hollow Shaft Absolute Encoder, 5/8"1 1/8" 1630mm. The HD25A is a NEMA 25 sized absolute encoder designed for industrial applications The HD25A optical encoder is a 12bit absolute rotary position sensor, which reports a shaft angle within a single 360 degree rotation of a shaft Unlike incremental, sometimes called relative style encoders, the HD25A provides true (absolute) shaft position, eliminating the need for a home or zero cycle after a supply voltage power cycle.

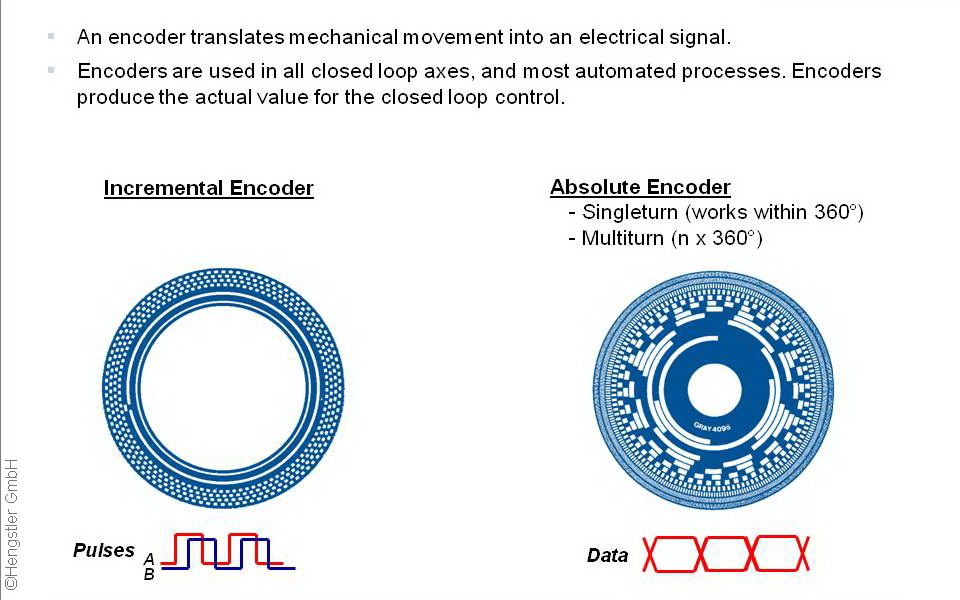

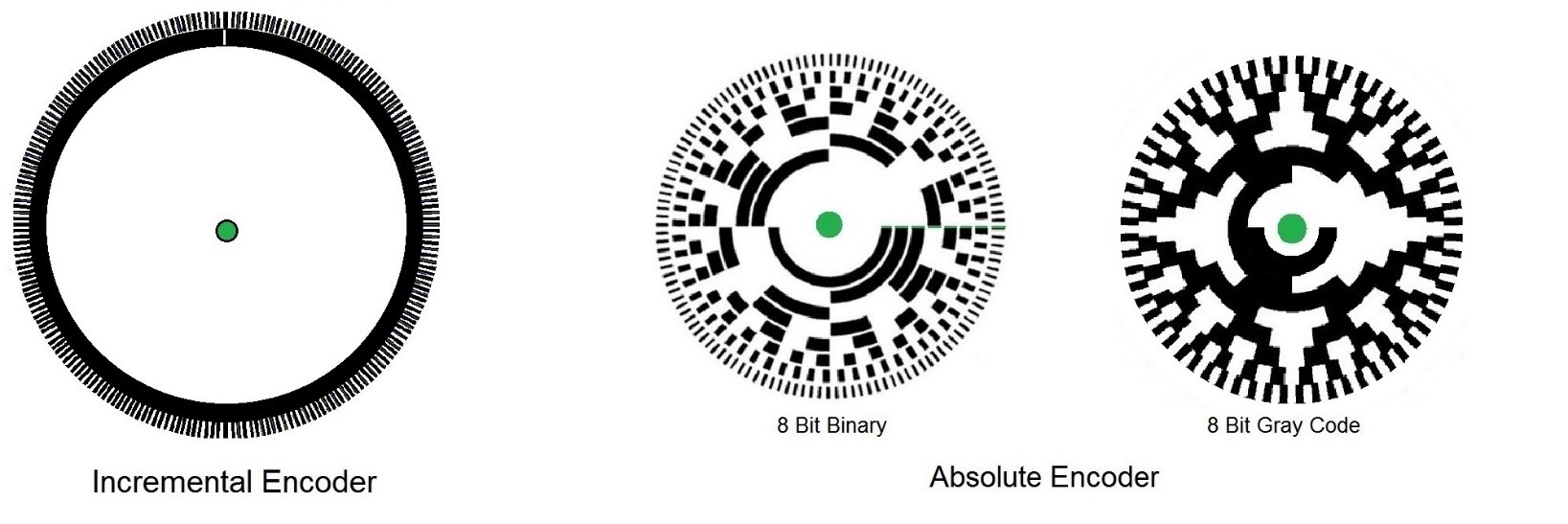

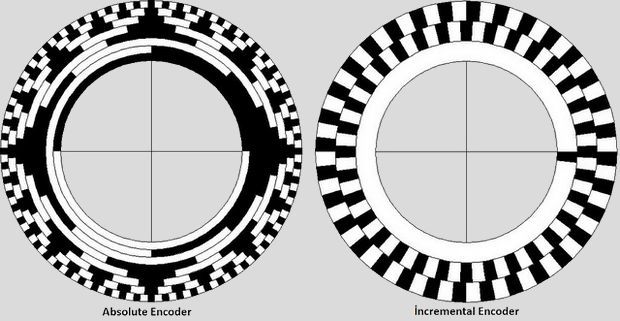

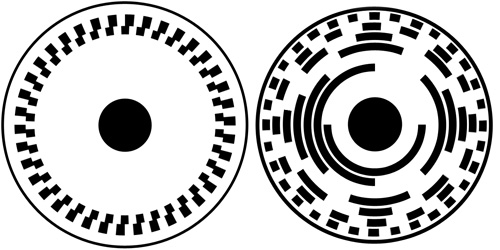

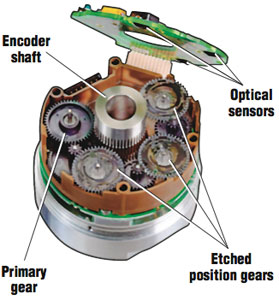

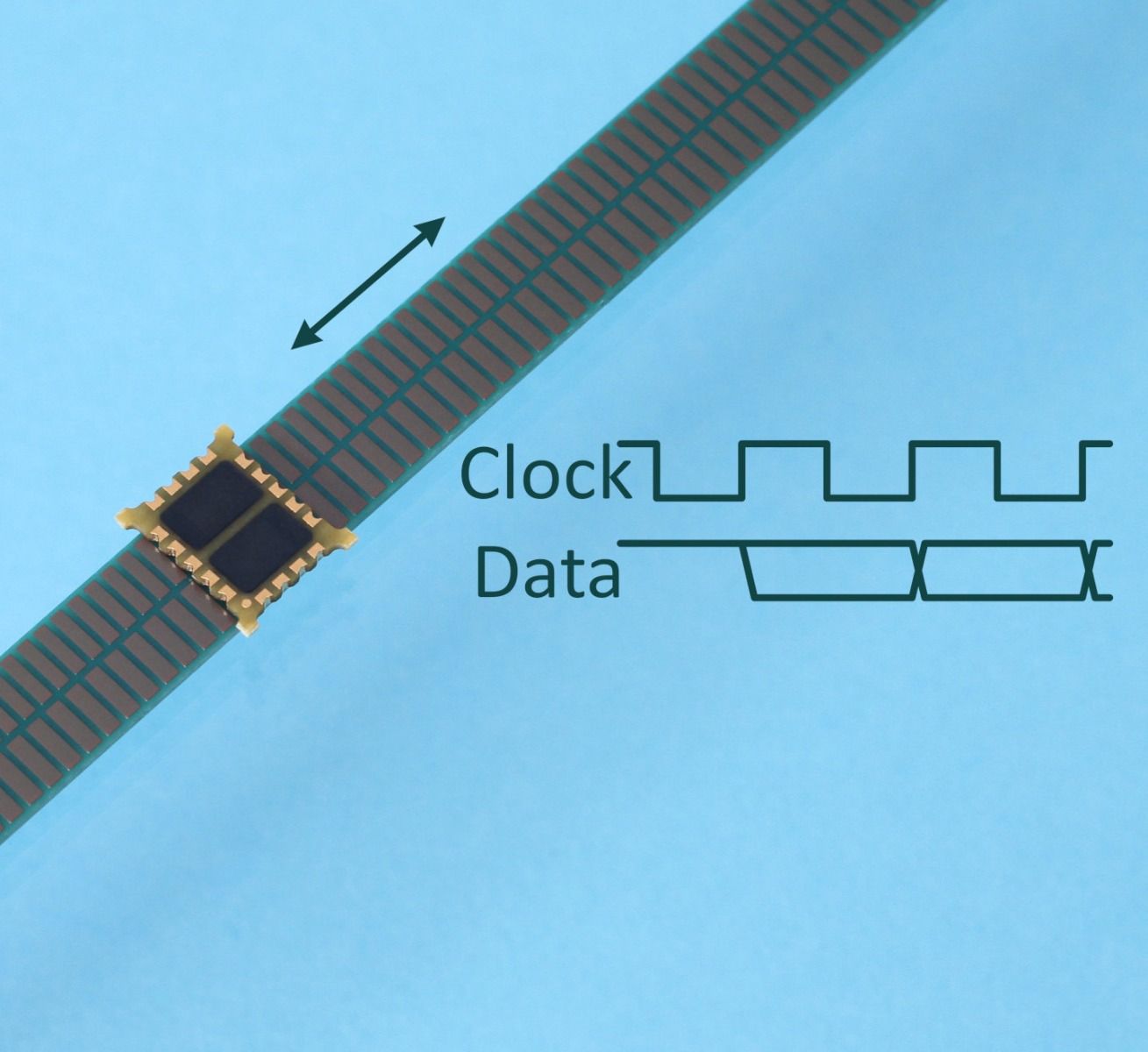

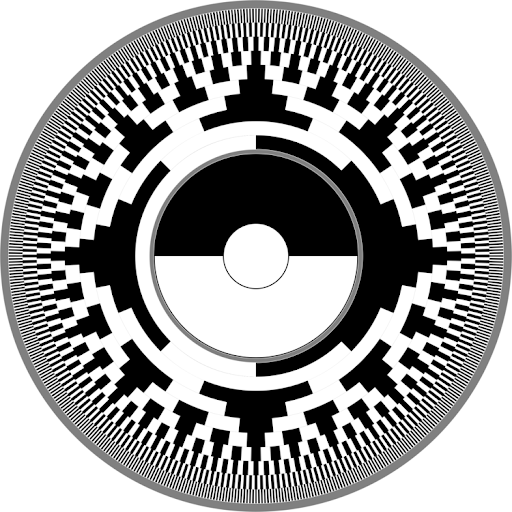

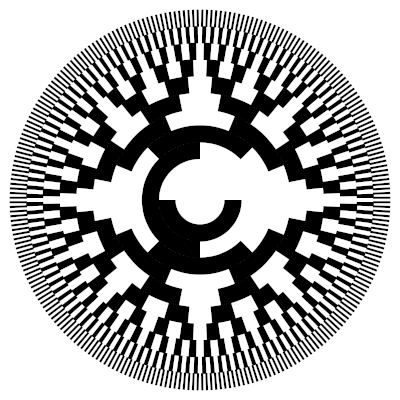

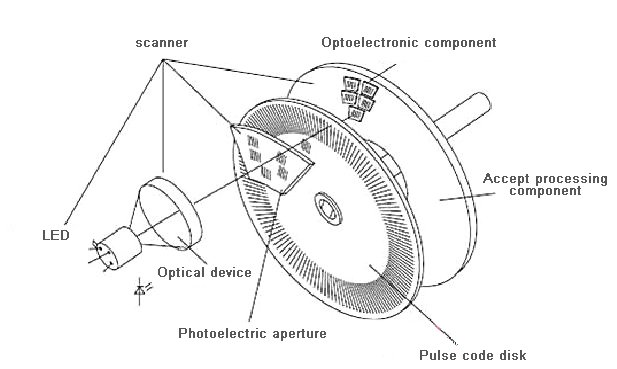

In a Rotary “Absolute” measurement type encoder, a slotted disc on a shaft is used in conjunction with a stationary pickup device When the shaft rotates, a unique code pattern is produced This means that each position of the shaft has a pattern and this pattern is used to determine the exact position. Types of Rotary Encoders and How does it work?. The absolute angle detection type encoder outputs the current absolute angle in a digital serial code or an analog voltage in response to instructions from the microcomputer Such an output way is called an absolute method Here again, we will explain its operation with the optical encoder as an example.

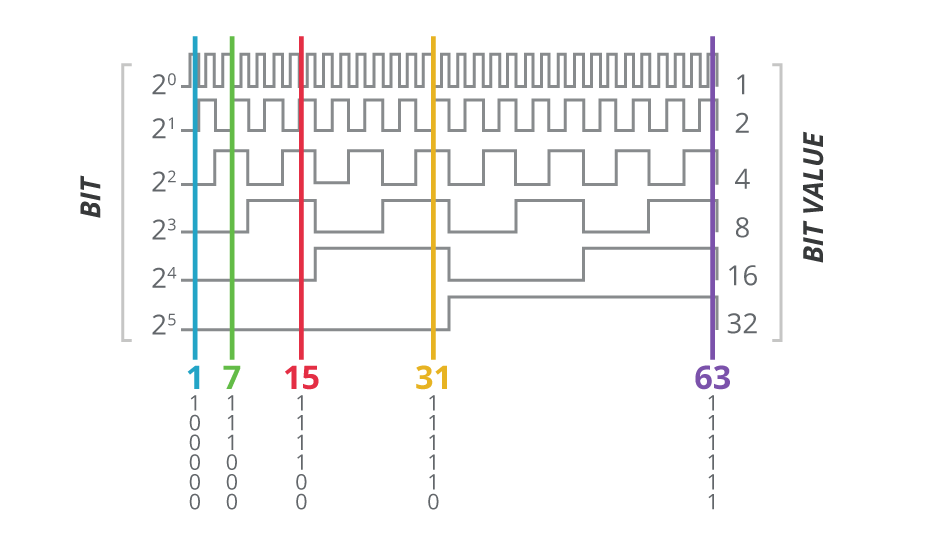

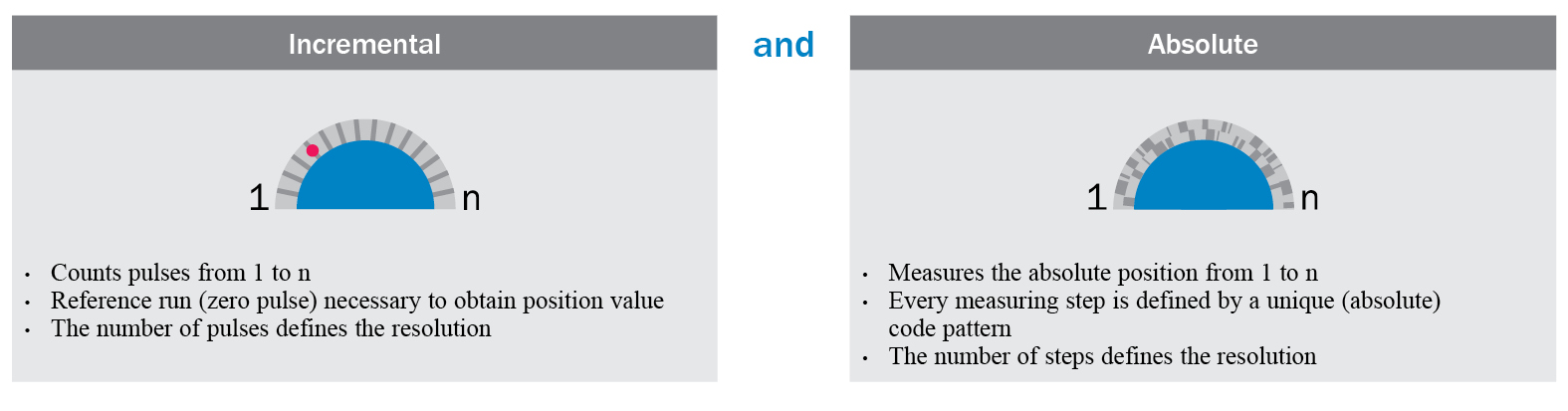

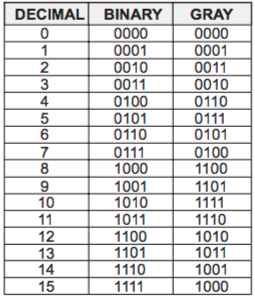

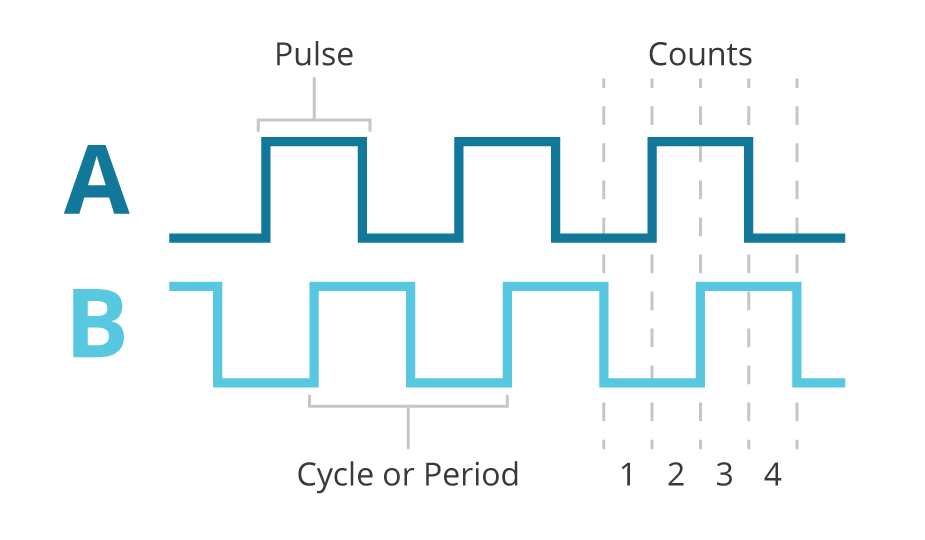

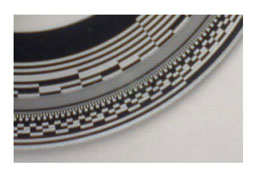

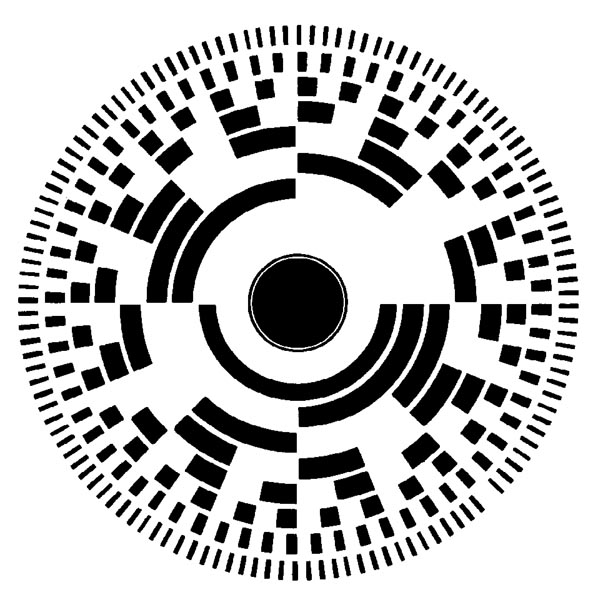

Absolute encoders output an absolute angular position between 0° and 360° They operate on the same scanning principle as incremental encoders, but have a greater number of tracks For example, if there are 13 tracks, then 2 13 = 8192 steps are coded in the case of singleturn encoders The code used is a onestep code (gray code). Absolute Encoders(MultiTurn) About Absolute encoder Absolute encoders output the absolute value of rotation anglesThe encoders are used for position control of servo motors mounted on machine tools or robotsAs shown in Figure 2, rotation slits are lined from the center on concentric circles Slits indicates binary code strings of 2 pulses/rev from the centerMultiturn absolute encoders memorize the rotation quantity data over one rotation. Absolute encoders are feedback devices that provide speed, position information by outputting a digital word or bit in relation to motion Unlike incremental encoders that output a continuous stream of ubiquitous pulses, absolute encoders output unique words or bits for each position.

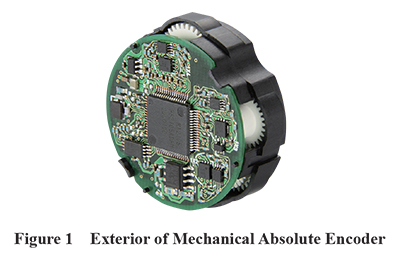

An absolute encoder works as a nonvolatile position verification device True position is not lost if power is lost or the system moves while power is switched off A continuous reading of position is not needed This is specifically useful in those applications, such as satellitetracking antennas, where position verification is key Absolute encoders also provide programming flexibility. Absolute rotary encoders use optical, mechanical, or magnetic indexing for angular measurement They do not lose their position after powerdown, but instead provide absolute position upon powerup without requiring a home cycle or any shaft rotation. An absolute encoder has a unique code for each shaft position which represents the absolute position of the encoder It directly provides the digital output representing the absolute displacement The value of the actual position is measured immediately the moment the system is switched on.

For more than 50 years, Encoder Products Company (EPC) has provided topquality motion feedback devices, with exceptional customer service and fast delivery At EPC, we are still filling most orders in 4 to 6 business days – that's days, not weeks. As the name suggests, an absolute encoder directly outputs the exact position of the shaft it is measuring Every point of rotation has a unique position value, or data word, which is encoded on a disc that rotates with the shaft The number of unique codes on the disc determines the precision with which the position can be expressed. The absolute rotary encoders in our product range are as varied as your individual requirements From standard/compact rotary encoders with optical or magnetic scanning with solid shaft, hollow shaft, blind shaft or integrated coupling through SIL3/PLe certified safety encoders and absolute encoders with fully encapsulated electronics for outdoor applications, to double rotary encoders in different housing sizes and a multitude of interfaces.

Absolute encoders produce a digital word value indicating true position within a full 360⁰ rotation The maximum practical resolution is approximately 16 bits (1 part in 65,536) Absolute encoders have a more complex installation and for high resolutions, the data is often sent serially with SSI being a common format. The absolute rotary encoders in our product range are as varied as your individual requirements From standard/compact rotary encoders with optical or magnetic scanning with solid shaft, hollow shaft, blind shaft or integrated coupling through SIL3/PLe certified safety encoders and absolute encoders with fully encapsulated electronics for outdoor applications, to double rotary encoders in different housing sizes and a multitude of interfaces. Our Absolute Encoders on EtherNet/IP connect to and operate with the Logix controllers to provide position tracking data to be used in openloop control systems Our Absolute Encoders are electromechanical devices that are useful feedback elements in closedloop control systems.

Absolute encoders produce a digital word value indicating true position within a full 360⁰ rotation The maximum practical resolution is approximately 16 bits (1 part in 65,536) Absolute encoders have a more complex installation and for high resolutions, the data is often sent serially with SSI being a common format. An absolute encoder has a unique code for each shaft position which represents the absolute position of the encoder, while an incremental encoder generates an output signal each time the shaft rotates a certain angle and the number of generated pulses is proportional to the angular position of the shaft. ABSOLUTE ENCODERS The other type of encoders are absolute encoders As the name suggests, this is the type of encoder that always knows where it is In other words, in opposite to relative encoders, you don’t need to "reinitialize" them They have a certain way to recognize that they are in a certain orientation.

CUI Devices' AMT absolute encoders are a highly rugged and accurate position feedback solution, thanks to their capacitive sensing technology The innovative platform offers resiliency to the dirt, dust, and oil typically encountered in motion applications Outputting 12bits or 14bits of absolute position information with SSI, SPI, or RS485 communication protocols, these absolute encoders feature low current draw, compact packages, simple assembly, and come available with up to 9. The absolute angle detection type encoder outputs the current absolute angle in a digital serial code or an analog voltage in response to instructions from the microcomputer Such an output way is called an absolute method Here again, we will explain its operation with the optical encoder as an example. ABSOLUTE ENCODERS The other type of encoders are absolute encoders As the name suggests, this is the type of encoder that always knows where it is In other words, in opposite to relative encoders, you don’t need to "reinitialize" them They have a certain way to recognize that they are in a certain orientation.

Overview Precise, flexible, versatile With a high resolution of 18 bits (AFS60) or 30 bits (AFM60) and a large selection of programmable parameters, the AFS60 absolute singleturn encoder and the AFM60 absolute multiturn encoder set new standards when it comes to rotary encoders The high resolution combined with the high IP protection class enables use in a multitude of industrial applications. An absolute encoder provides a unique position value or data word at every point of rotation representing the “absolute” position of the encoder From the moment you switch it on, an absolute encoder can tell you the exact position of the rotating shaft that it is measuring. Absolute encoders generate information about position, angle, and rotation counts in typespecific angle steps For this, a unique code pattern is assigned to each angle increment The number of code patterns available per revolution determines the resolution Each code pattern forms a unique reference, and is therefore an absolute position.

In the encoder world, one size does not fit all and our diversified line of absolute encoders ensures that we have the right product for your unique applications Big, small, heavy duty, watertight, ATEX and SIL, we’ve got you covered All the major Fieldbus, Ethernet and discrete interfaces for you to choose from. Absolute Encoders Hohner Automaticos offers a complete range of absolute encoders. Absolute rotary encoders provide a distinctly coded numerical value for each shaft position In positioning tasks in particular, the absolute encoders relieve the controller of computation tasks and keep costs down by eliminating the need for additional input components.

Absolute rotary encoders provide a distinctly coded numerical value for each shaft position In positioning tasks in particular, the absolute encoders relieve the controller of computation tasks and keep costs down by eliminating the need for additional input components. Our AI25 SSI Absolute Encoder offers up to 22 bit singleturn and 12 bit multiturn positioning, board temperature range, onboard diagnostics and multiple shaft sizes Discover more here!. Close loop applications of Encoder.

An absolute encoder provides a unique position value or data word at every point of rotation representing the “absolute” position of the encoder From the moment you switch it on, an absolute encoder can tell you the exact position of the rotating shaft that it is measuring. We put a spin on things with even more interfaces and customizability In the encoder world, one size does not fit all and our diversified line of absolute encoders ensures that we have the right product for your unique applications Big, small, heavy duty, watertight, ATEX and SIL, we’ve got you covered All the major Fieldbus, Ethernet and discrete interfaces for you to choose from. Encoders can electronically monitor the position of a rotating shaft Our Absolute Encoders on EtherNet/IP connect to and operate with the Logix controllers to provide position tracking data to be used in openloop control systems Our Absolute Encoders are electromechanical devices that are useful feedback elements in closedloop control systems.

Absolute encoders provide an absolute numerical value for the shaft position, either for only one revolution (singleturn) or including the number of shaft revolutions (multiturn) The output is given in binary form The larger the number of bits, the greater the resolution. Absolute encoders Nikon absolute encoders employ Nikon's unique optics technology and absolute pattern technology utilizing its Msequence pattern, enabling both miniaturization and high reliability. Encoders Absolute Encoder Square Flange, Shaft Seal, 10 bits Natural Binary, 528V in/out, clockwise increase count, End Output Termination, 19pin connector Enlarge Mfr Part # Mouser Part # BEI Sensors Encoders Absolute Encoder Square Flange, Shaft Seal, 10 bits Natural Binary, 528V in/out, clockwise increase count, End Output Termination, 19pin connector.

The main difference is that an absolute encoder will detect the absolute position of the encoder, while incremental encoders will only detect changes in movements Incremental Encoder An incremental encoder has two output signals A and B, which are quadratureencoded Meaning, when the encoder is moving at a constant velocity, each pulse has. Absolute Encoder by Hengstler HENGSTLER's ACURO absolute rotary encoders offer innovative engineering, easy operation and optimised functional dependability The platformbased concept enables particularly compact construction and modular internal components As a result of this sophisticated modular system, HENGSTLER is in a position always. Absolute encoders provide position information for a rotating shaft within either a single rotation (single turn) or over the course of multiple rotations (multiturn) The encoder provides a unique digital code or bit for each increment of shaft rotation Multiturn absolute encoders store turnscounting information for instant retrieval, even after power down.

An absolute encoder has a unique code for each shaft position which represents the absolute position of the encoder, while an incremental encoder generates an output signal each time the shaft rotates a certain angle and the number of generated pulses is proportional to the angular position of the shaft. Absolute Encoders retain your position data during loss of power They are excellent choices in systems that require failsafe operation Our magnetic encoders directly connect to DeviceNet™ for advanced functionality with reduced wiring cost. The absolute encoders Multiturn Sendix 5868 / 58 with PROFINET IO interface and optical sensors can be used in all applications with Profinet technology These encoders support IRT mode and are therefore ideally suited for realtime applications Connectivity.

Absolute singleturn encoder, 36 mm Magnetic sensing Protection up to IP67 with sealed circuit. Our EtherNet/IP™ Absolute Encoders are designed with an embedded EtherNet/IP switch and dual Ethernet ports to support linear networks and Device Level Ring topologies By providing auxiliary feedback directly through an EtherNet/IP network, these encoders eliminate the need for pointtopoint wiring. An absolute encoder generates a unique code for each position When powered up, these absolute encoders do not require a home cycle even if the shaft was rotated while the power was switchedoff Broadcom absolute encoders in this category use optical technology or Hall effect sensing technology to sense positional information.

Mechanical Absolute Rotary Encoders An absolute rotary encoder is one that measures an absolute angle of the encoded Optical Absolute Rotary Encoders Optical absolute rotary encoders are constructed with either glass or plastic material Magnetic. Absolute encoders are of two types Single turn absolute encoder provides information for any increment within one shaft rotation Multi turn absolute encoders are provides information for multiple shaft rotation as many as half billion shaft rotation Thus exact shaft rotation is known even after power interruption;. 041A6408 Absolute Encoder Kit Find Replacement DEALERS NEAR ME Overview Compatibility Compatibility The 041A6408 is compatible with the following 8500 DC Battery Backup Capable Wall Mount Garage Door Opener 8500c Elite Series® Battery Backup Capable Wall Mount Garage Door Opener Installation & Support.

Ac58 Profibus Absolute Rotary Encoder Absolute Rotary Encoders Impulse Automation Ltd

007 Absolute Encoder 4 Track Robotics Business Review

When Is An Absolute Encoder Right For Your Design Cui Devices

Absolut Encoder のギャラリー

Rotary Encoder Establishes Absolute Position At Start Up

Ac58 Profinet Absolute Rotary Encoder Absolute Rotary Encoders Impulse Automation Ltd

Baumer Gxmmw 03p32 Absolute Encoder Jordan Anwar Est

E6f Ag5c C 360 2m Omron Absolute Encoder Omron E6f Ag5c C 360 2m 360 Ppr 5000rpm Ssi Gray Solid 12 24 V Dc 2 6405 Rs Components

How Encoder Resolution Is Determined

Encoder Definition

Absolute Optical Encoder For Position Transducers

Ezautomation Industry Article High Speed Rotary Encoders

Rotary Encoder Wikipedia

Absolute Encoder Disc Low Price Optical Rotary Encoder Disks Buy Encoder Schijven Rotary Encoder Schijven Optische Encoder Schijven Product On Alibaba Com

What S The Difference Between Absolute And Incremental Encoders Machine Design

Absolute Rotary Encoders Dynapar

Encoder Angle Measurement Ccs C Pic16f628 Sample Application Electronics Projects Circuits

Incremental Encoder And Absolute Encoder

Direct Drive Rotary Servo Tables Fitted With Absolute Encoders

Encoder Primer Phidgets Support

Reautomatico Rotary And Linear Encoders And Sensors Specialists Lir Da2110 Big Hollow Shaft Optical Absolute Encoder

Nikon News Mar M40as And Mar Mk42as Multi Turn Absolute Encoders Released

Autonics Rotary Encoder Incremental Absolute Encoders At Rs 5000 Unit Absolute Encoders Id

What Is An Absolute Encoder When To Use It Quickmechy

Absolute Encoders

Mra50a Absolute Encoder Althen Controls

Using Encoders In Motion Control Automated Motion Systems Pty Ltd Australia

Absolute Encoders Solidswiki

Absolute Encoders Versus Incremental Encoders

Absolute Encoders Youtube

Calt 12 Bit 4096 Resolution 10mm Shaft Rs485 Interface Single Turn 360 Degree Absolute Encoder Amazon Com Industrial Scientific

Q Tbn And9gcrghy9iknkbs Xexofjpzi85p1z21hnx0yu4qv3h Vjdzdu1jhs Usqp Cau

Absolute Or Incremental Encoders The Differences Explained Sick Usa Blog

Rotary Encoder Absolute Encoder Hs6a

Absolute Encoders

Wdga 58bcoab00cb5 Magnetic Absolute Encoder 12 Bit 10 32v 8000min Sup 1 Sup Wachendorff

What Is An Absolute Encoder Zettlex Inductive Encoders

Absolute Linear Encoder Chip Ap5603l Posic

Q Tbn And9gcqblk3lkcrx8vu Lo9w4 8r8gcpu49omosearounb J msar Usqp Cau

Absolute Encoders

Ad36 0013ef 0rscb Hengstler Absolute Encoder Hengstler Ad36 0013ef 0rscb 48 Ppr rpm Ssi Gray Hollow 7 30 V Dc 666 62 Rs Components

Industrial Encoders Absolute Baumer International

New E6c3 Ag5b 256 360 7 1024p R Gray Code Absolute Encoder Rugged Rotary Encoder Level Measuring Instruments Aliexpress

.jpg)

Absolute Vs Incremental Encoder What Is The Difference Advantages And Disadvantages

Mrv50f Absolute Encoder Althen Controls

Gowe Optical Absolute Encoder 10mm Shaft Absolute Linear Position Sensor Parallel Ssi Encoder Color Ssi Amazon Com Industrial Scientific

Absolute Encoders Van Tsb Bescom Leveren Betrouwbaarheid

Ad36 0013ef 0rscb Absolute Encoder Hengstler Ad36 0013ef 0rscb 48 Ppr rpm Ssi Gray Hollow 7 30 V Dc Rs Components

Absolute Encoders Multiturn Kubler Group Worldwide

Hall Effect Absolute Encoder Mab12a

Liftmaster 41a6408 Absolute Encoder Travel Module

Industrial Absolute Rotary Encoders Posital

When Is An Absolute Encoder Right For Your Design Cui Devices

Faq What Are The Ways To Wire An Absolute Encoder Into A Motion System

Rotary Encoder Wikipedia

What Is An Absolute Encoder Zettlex Inductive Encoders

1

Absolute Encoders Atm60 Profibus Sick

Xcc3515cv84fbn Absolute Encoder O 58 Multi Turn Hollow Shaft 15 Mm 25 Bit Binary Profibus Schneider Electric Global

Pin On Research Engineering

Fvm58n 02lk2r0gg 0506 Pepperl Fuchs Multiturn Absolute Encoder

Hs35 Parallel Analog Ssi Sensata Technologies

Absolute Encoders

Absolute Encoder Wv58mr News Siko Gmbh

Kuebler Absolute Encoders एब स ल य ट इनक डर Orchid Technology Ahmedabad Id

.jpg)

Absolute Vs Incremental Encoder What Is The Difference Advantages And Disadvantages

When Is An Absolute Encoder Right For Your Design Cui Devices

China Yumo Gax60 R13 12 E10 Lb Absolute Encoder Linear Encoder China Absolute Encoder Motor Encoder

Principle Of Single Track Absolute Encoder Download Scientific Diagram

Absolute Position Encoder With Non Contact Magnetic Sensor

Incrementele Encoders En Absolute Encoders Pulsgevers Fortop Nl

Absolute Encoder Disk Download Scientific Diagram

Meyle Absolute Encoder

Absolute Encoder Shaft Encoder Rotary Encoder How It Works Youtube

Us Digital Products k Absolute Optical Encoder Kit Version

Solved Problem 2 The Gray Code Of An Absolute Encoder Chegg Com

Absolute Position Encoder With Non Contact Magnetic Sensor

Incremental And Absolute Encoder Shielding Hohner Automazione Srl

Absolute Encoders Multiturn Kubler Group Worldwide

Q Tbn And9gcq5 Uhjdhn Ji7o Kjbatmdi31wlwpwnhtdlshikbgwusyhyy5o Usqp Cau

Okuma Er Jd 70d Absolute Encoder General Servo Spindle Motors

Stepper Motors Astep Battery Free Absolute Encoder Stepper Motors

Wh58mr Absolute Encoder Siko Global Com

Autonics Absolute Rotary Encoder Ep58hb8 7 1f N 24 At Rs Pack Absolute Encoders Id

Encoders Optical And Magnetic Incremental And Rotary

Low Price Single Lap Absolute Encoder Ssi Interface Output 14 Bits Resolution Cas60r14e10sgb Angle Position Sensor Level Measuring Instruments Aliexpress

What Is The Difference Between Absolute And Incremental Encoders Realpars

What S The Difference Between Absolute And Incremental Encoders Yueqing Yumo Electric Co Ltd

Absolute Rotary Encoders Dynapar

Absolute Encoder एब स ल य ट इनक डर Unicorn Automation Private Limited Dehradun Id

E6f Ag5c C 256 2m Absolute Encoder Omron E6f Ag5c C 256 2m 256 Ppr 5000rpm Ssi Gray Solid 12 24 V Dc Rs Components

Reautomatico Rotary And Linear Encoders And Sensors Specialists Lir Da290 Big Hollow Shaft Optical Absolute Encoder

Absolute Optical Encoders Machine Design

How Encoders Work Pca Encoders

Optical Encoders Code For Free

Wdga 58eieub01bi2 Magnetic Absolute Encoder Binary Ethercat Profinetio 16 Bit St 16 Bit Mt 10 32v Wachendorff

Ethernet Ip Absolute Encoders For Time Critic

Absolute Vs Incremental Encoder What Is The Difference Advantages And Disadvantages

What Is The Difference Between Absolute And Incremental Encoders Realpars

Encoders Optical And Magnetic Incremental And Rotary

Absolute Encoder Hengstler Gmbh

How Do Absolute Encoders Work

Control Engineering Reinventing Absolute Rotary Encoders

Incremental Encoders And Absolute Encoders Transducers Fortop Uk

Faq What Is The Difference Between Absolute And Incremental Encoders