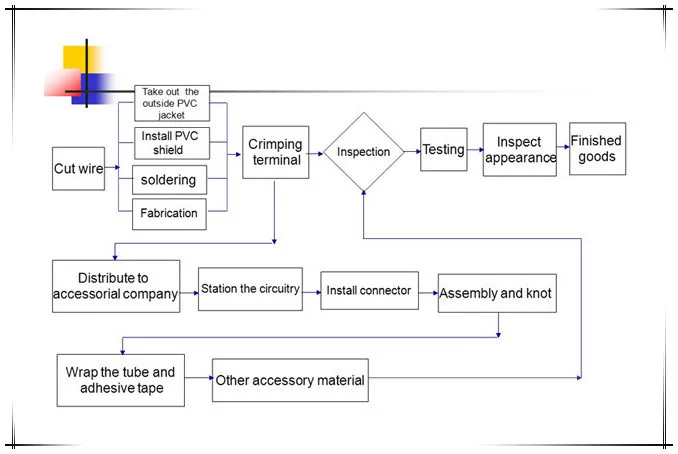

Cable Assembly Process

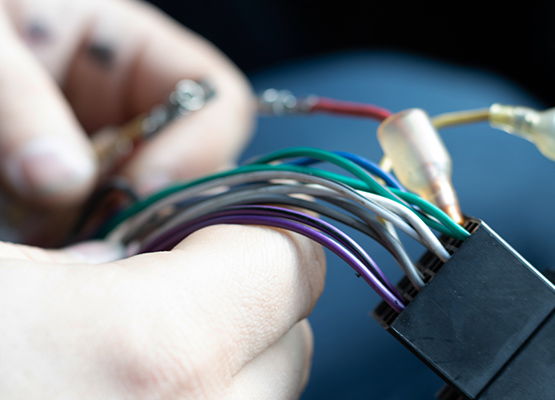

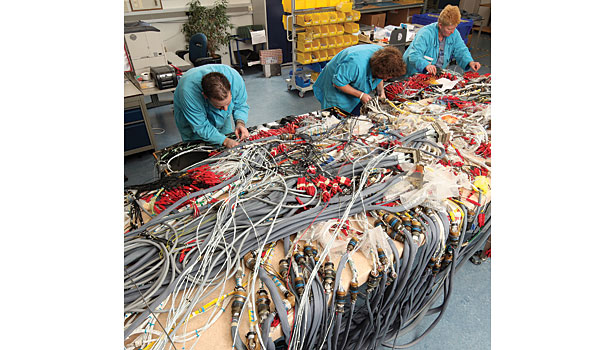

Manual Assembly Manual assembly involves the composing of previously manufactured components and/or subassemblies into a complete product of unit of a product, primarily performed by human operators using their inherent dexterity, skill and judgment From Process Selection (Second Edition), 03 Related terms Reliability Analysis;.

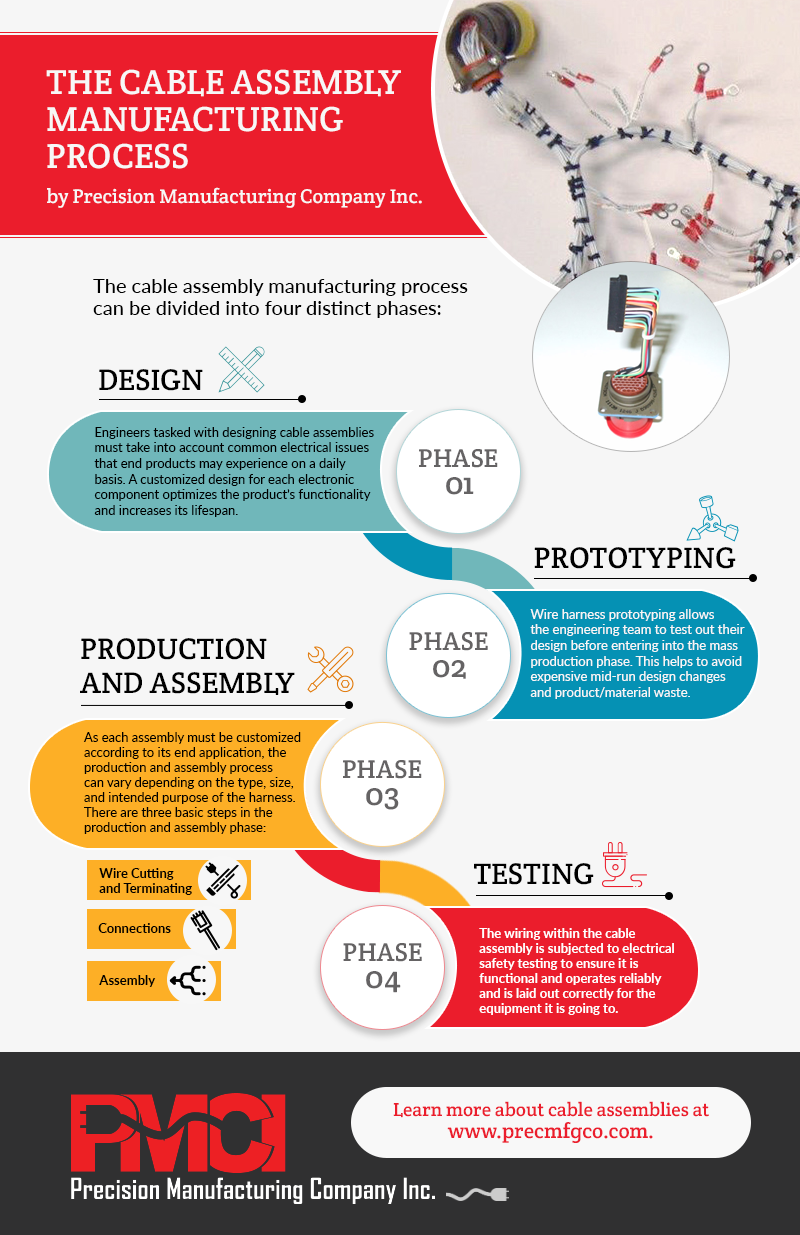

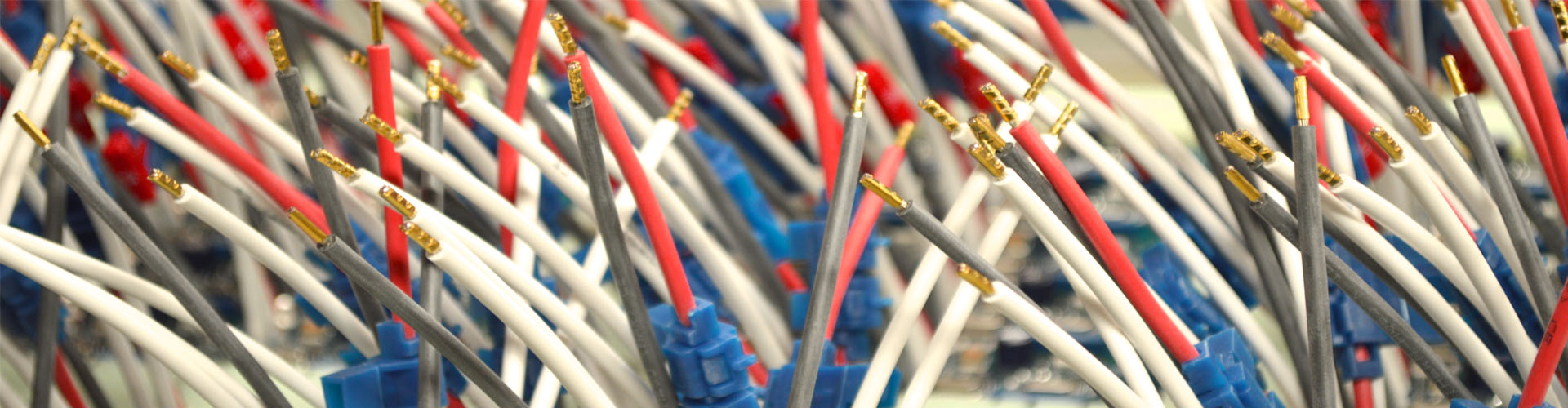

Cable assembly process. What Is A Cable Assembly, The Process, and 5 Common Cable Harness 7/4/19 One of the most significant elements of an electronic or electrical system is the cable assembly But still, it is one of the last components that is addressed or given importance to In fact, an over or under designed cable assembly will have a tremendous negative. Strict process control also allows for consistent and low pricing Our cable assembly pricing is among the lowest in America Our processes regularly incorporate various sizes and types of wire, solder and crimp terminals and pins, and customerspecific electronic components Capabilities include cutting and following cables at specified. The process is adequate for cable breakouts or Y/J Junctions This kind of assembly connector also works as an anchor point called cable stops Extra protection to the exposed joints of the cable assembly in the form of seals and glands offers endurance To grasp the concept better, refer to this video that tells you all about a molded cable.

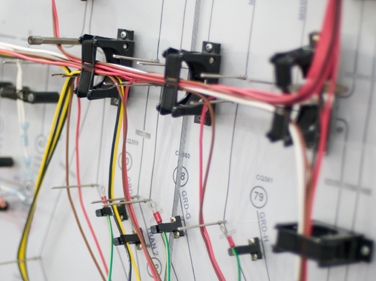

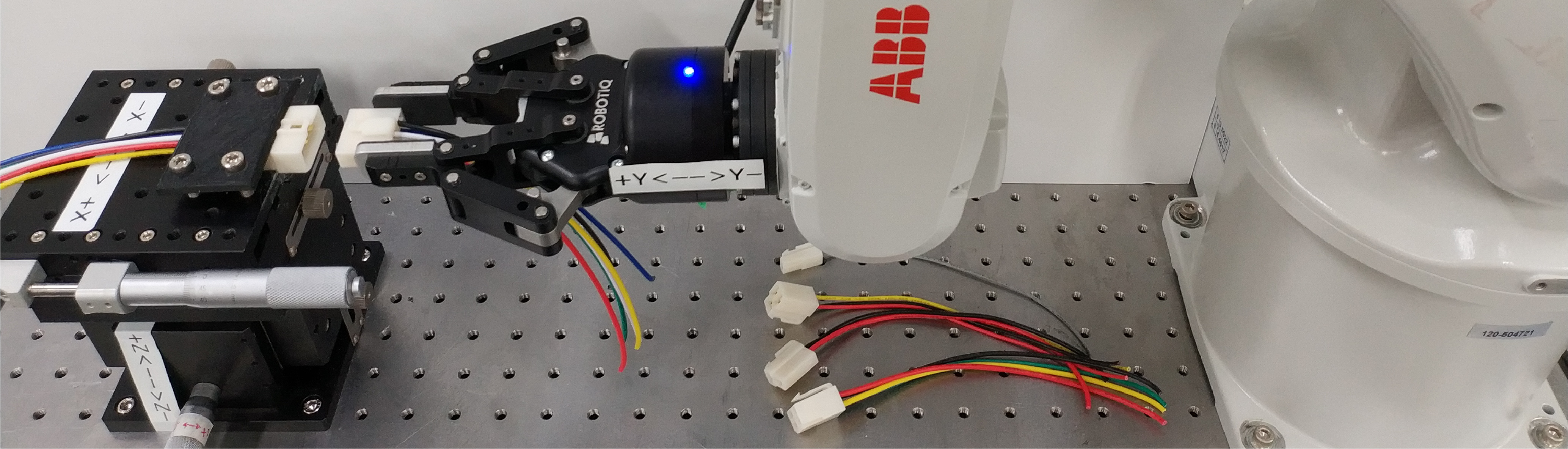

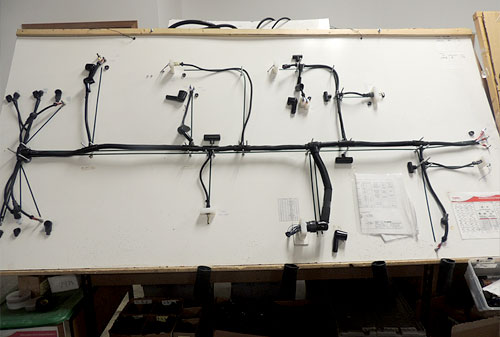

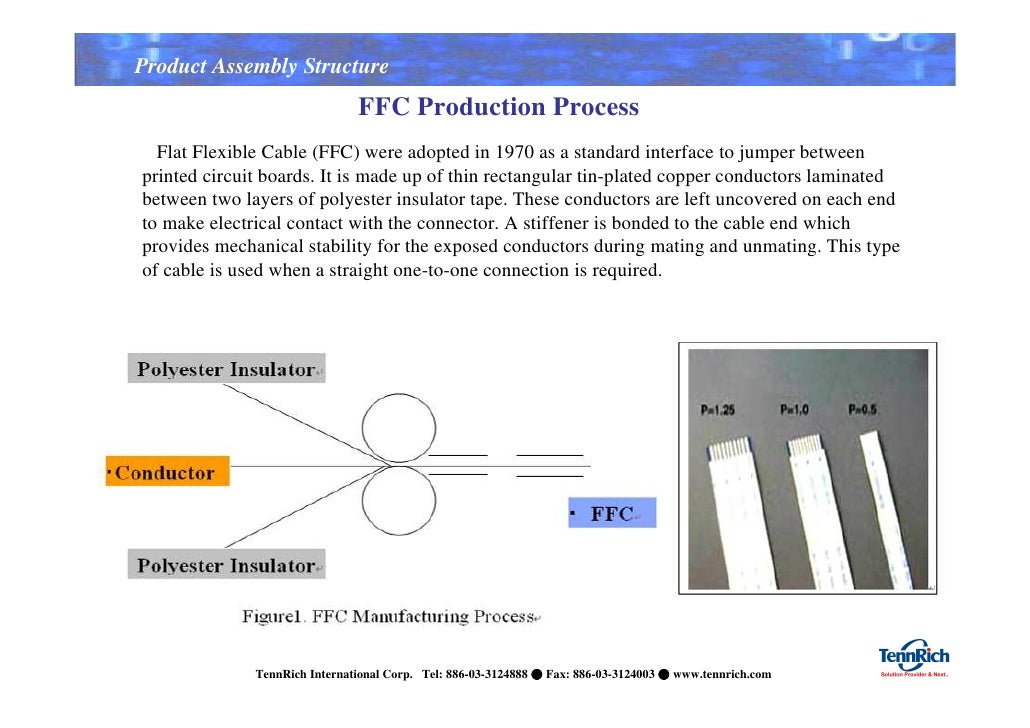

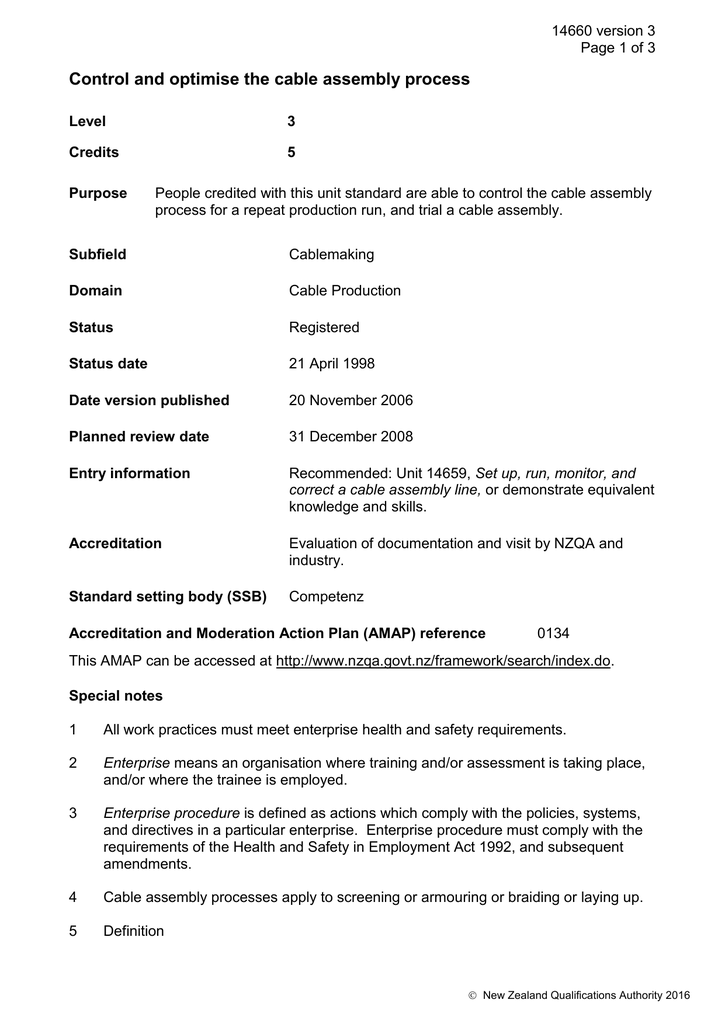

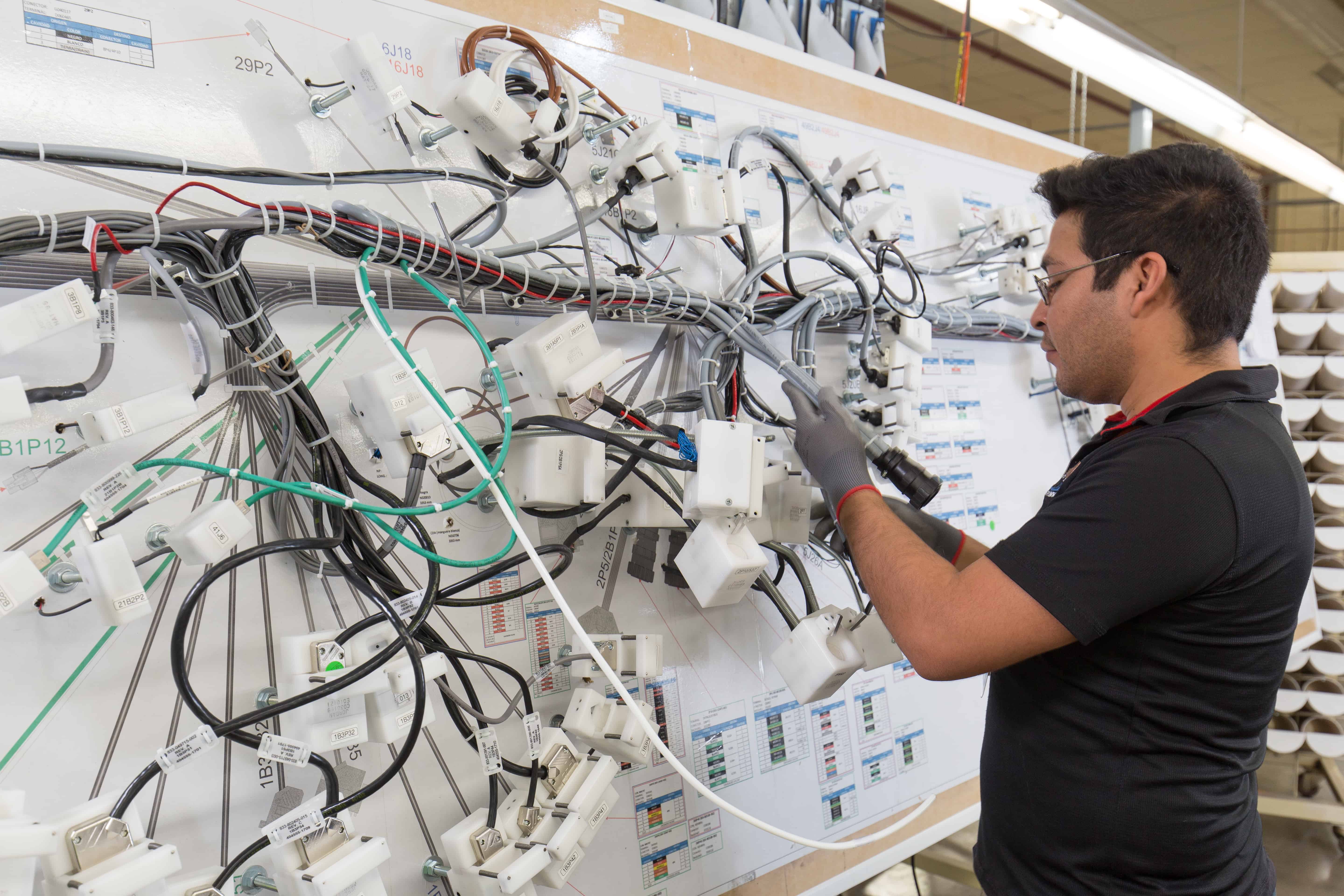

Process Our facility uses stateoftheart equipment to process orders We focus on highquality production of cable and wiring systems that perform reliably in a variety of environments Our finishing and assembly services include wire cutting, stripping, and terminating, as well as tin and solder services. Cable surfaceSubcabling permits neat and simple formation of branch legs from the main cable and can be used to aid in identifying wire groups For plastic jacketed cables, typical wall thickness is 10% of the unjack eted diameter or 0010” minimum Cable jacket walls below 0010” are not Subcables may be individually jacketed. Though some automation can be incorporated into the process, hand manufacturing of wire harnesses and cable assemblies are necessary due to the many intricate and time consuming steps involved in completing the process Even though building a wire harness can be difficult and task oriented, manual production remains more cost effective.

Wire Harness Manufacturing Process Precision Cable Assemblies (PCA) has a continual wire harness manufacturing process improvement program embedded in each of its manufacturing facilities To resolve this inspection challenge, and meet the desired parts per million rates, the manufacturing team members came up with a unique solution. A Wire Harness Manufacturer is a company or business that provides services to complete the wire harness assembly process A wire harness is an assembly of wires, cables and connectors that transmit electric power or signals Complete on site services include cutting, stripping, crimping, soldering, as well as the assembly of wires in a wide range. The process of taking two plastics and forming them together by ultra sonic plastic welding Quality Assurance – Signal Integrity Analysis Each completed assembly is electrically tested for faults This testing includes but is not limited to opens, shorts, shield integrity, and correct pinouts Quality Assurance – Insertion Loss Analysis.

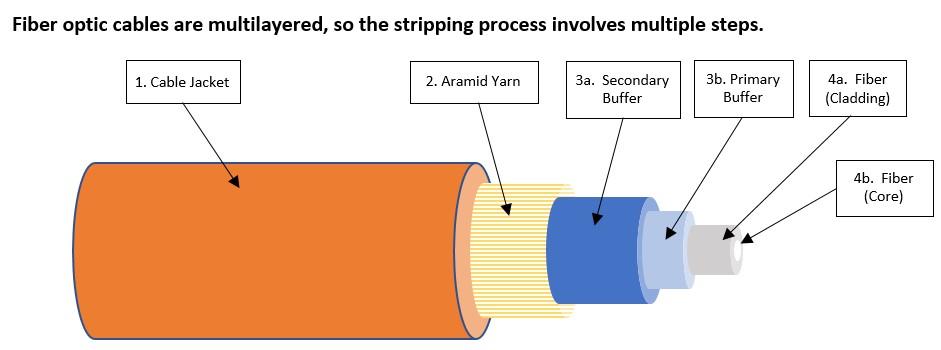

In the fiber optic cable assembly, the aramid strength members provide tensile strength from the connector and throughout the cable For example, during the manufacturing process, as you pull the cable onto the connector, the aramid strength members help to assure the cable and the glass optic fiber won’t break. Contract manufacturers often build both cable assemblies and wire harnessesTo distinguish between the two, a cable assembly is an external connection to devices and will have different environmental considerations, such as their thickness, insulation type, and flexibility. Simple cable harnesses, complex harnesses and molded cable assemblies are each built in different cells Because Arrow wanted to ensure that standardization by part number would comply with future processes, the company focused on one cell.

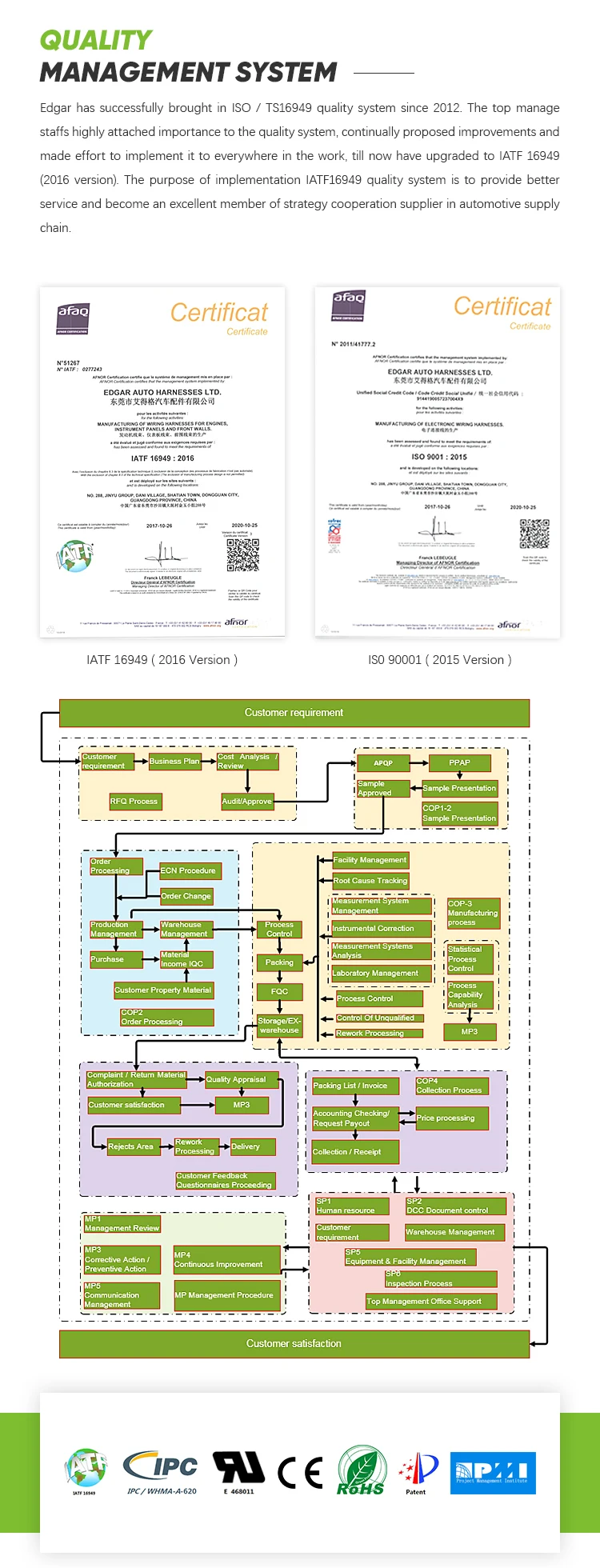

Wire Harness and Cable Processing ACDi utilizes automated wire processing equipment to measure, cut to length, strip and terminate discrete wires for standalone wire harnesses, as well as harnesses used in the final assembly of electromechanical chassis related assemblies and integrated box build products. An assembly is typically used for either transmitting informational signals or power Cable assemblies are often found on aircraft The typical structure for a cable assembly is a group of wires or cables connected at each end by a single piece, which then plugs into a power source. Cable Assembly Manufacturing Top quality, tested equipment, ongoing training and the latest technologies allowed our cable assembly and wire harness manufacturing process to achieve one of the highest marks in the industry Over 700 employees in more than 190,000 square feet facilities are committed to top quality standards.

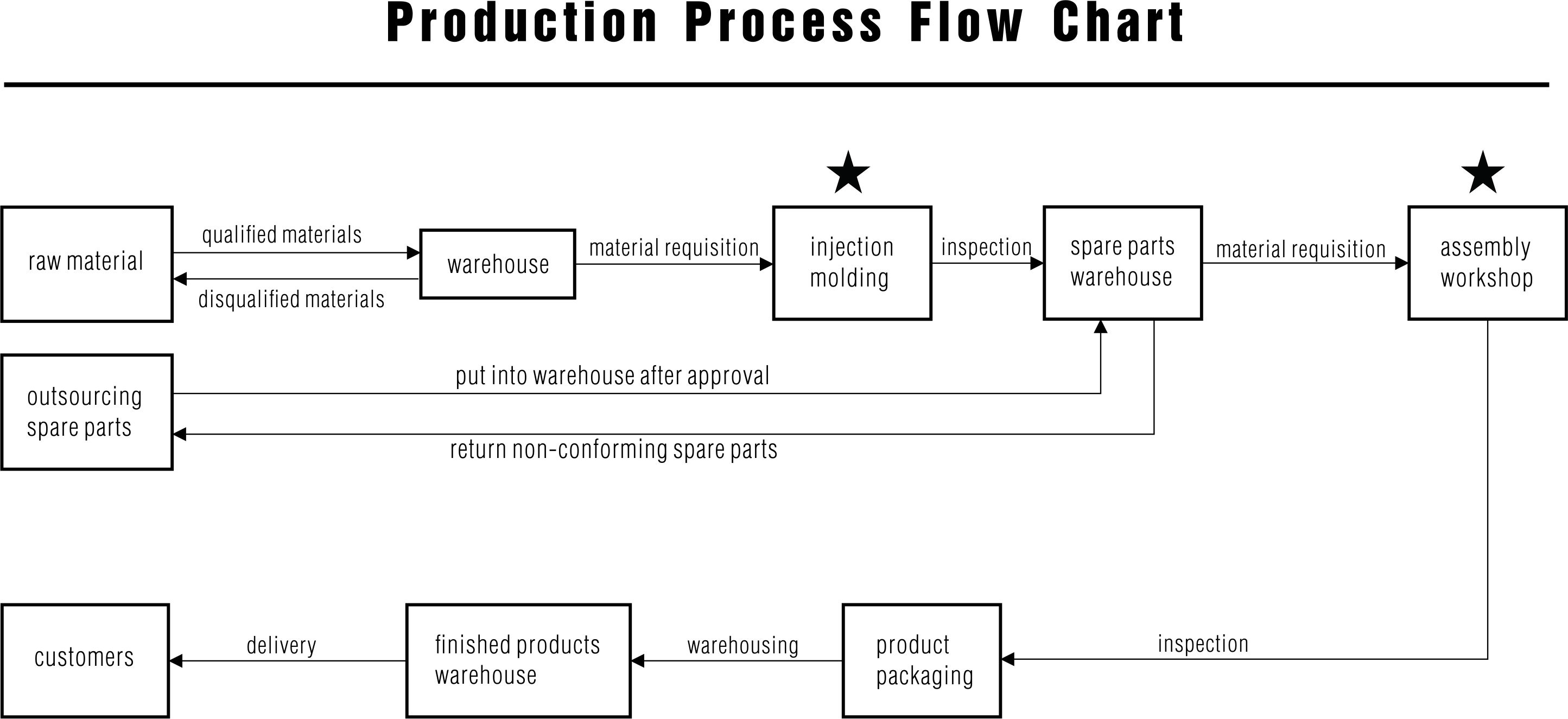

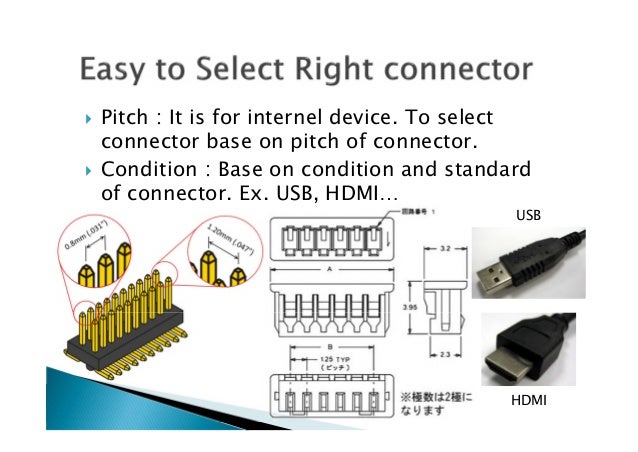

This solidifies into a shape that conforms. The product after assembly ‘Optimization of the manufacturing process’ DFA is a tool used to select the most cost effective material and process to be used in the production in the early stages of product design. All electrical connecting cables, be it HDMI, DisplayPort, USB, USB Type C cables, essentially have two major components 1) the cable and 2) the connector All material constituents of these two parts, therefore including the wires, the conductor housing (shell), the terminals, plastic, etc undergo stringent raw material inspection.

Contract manufacturers often build both cable assemblies and wire harnessesTo distinguish between the two, a cable assembly is an external connection to devices and will have different environmental considerations, such as their thickness, insulation type, and flexibility. The same cable assembly was rarely, if ever, built the same way twice Additionally, product flow was never established, and setup and changeover were lengthy and chaotic Other major anomalies in the system included having a push system of material flow to the production area, excessive inventory with no regard for justintime delivery, and. CABLE AND HARNESS GENERAL REQUIREMENTS (cont) PREFERRED CONNECTOR STYLE Connectors shall be straight, rightangle or flangemount The use of rightangle connectors shall be minimized and restricted to applications where stressfree mounting of the cable assembly can be assured.

Cable Assembly & Wire Harness Solutions Regardless of the connectors you specify to your application, we can customize and manufacture a cable that ideally meets your requirements This equipment capability together with integrated process controls ensures that our customers receive the highest quality product at the most cost competitive. Wire Harness and Cable Assembly Manufacturing Process Driven Customer Centered ADCE (Amphenol DC Electronics) specializes in the design, engineering and manufacturing of custom wire harnesses, cable assemblies and related subassemblies Founded in 1979 by the Cianciulli Family, ADCE built a reputation of uncompromising quality, innovation. Winchester Interconnect specializes in cable assembly overmolding, using the most durable raw materials to withstand harsh environmental conditions, abrasion, and sterilization procedures Overmolding, or Injection Molding, is a process that utilizes molten plastic material injected into a mold cavity;.

For instance, surface mount assemblies, which are sometimes referred to as wiring assemblies or cable harnesses, consist of a group of cables, wires, and subassemblies used for transmitting electrical power or signals However, there is an actual cable assembly that should not be confused with a harness assembly. Wire Harness Manufacturing Process Precision Cable Assemblies (PCA) has a continual wire harness manufacturing process improvement program embedded in each of its manufacturing facilities To resolve this inspection challenge, and meet the desired parts per million rates, the manufacturing team members came up with a unique solution. Wire Harness Manufacturing Process Precision Cable Assemblies (PCA) has a continual wire harness manufacturing process improvement program embedded in each of its manufacturing facilities To resolve this inspection challenge, and meet the desired parts per million rates, the manufacturing team members came up with a unique solution.

When it comes to building highquality cable assemblies, extrusion is a crucial piece of the manufacturing process Extrusion is the process of manufacturing a cable assembly’s cross sections These cross sections must be absolutely uniform in order for the system to perform at its best. As crucial as PCB cable assembly is, many people tend to focus on this part of the process as the final piece The reality is that your cable assembly consists of many different components that affect the entire electrical system For example, connectors determine device compatibility, while conductors determine the efficiency of the current flow. In the fiber optic cable assembly, the aramid strength members provide tensile strength from the connector and throughout the cable For example, during the manufacturing process, as you pull the cable onto the connector, the aramid strength members help to assure the cable and the glass optic fiber won’t break.

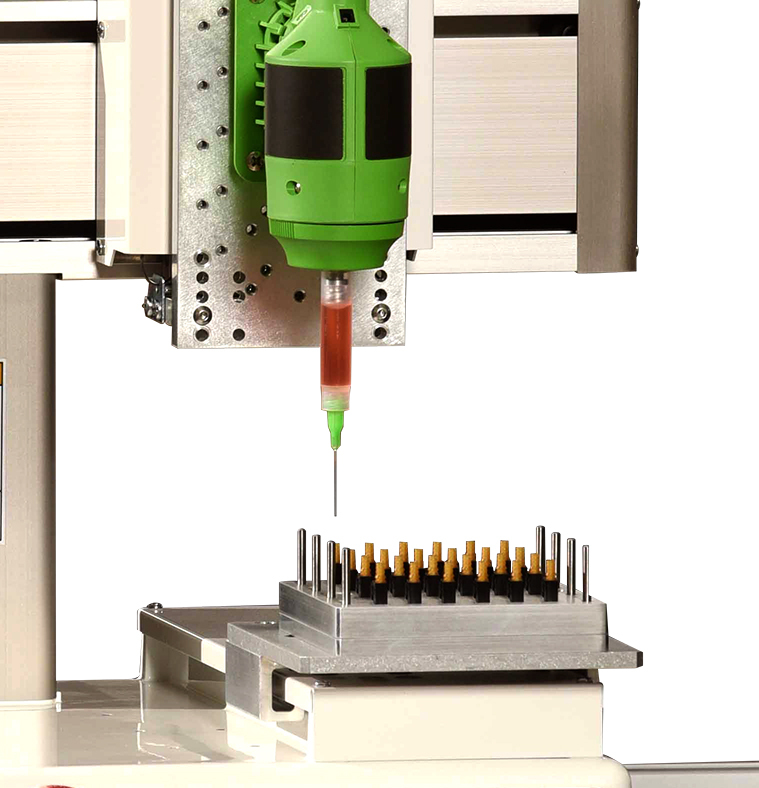

Process Our facility uses stateoftheart equipment to process orders We focus on highquality production of cable and wiring systems that perform reliably in a variety of environments Our finishing and assembly services include wire cutting, stripping, and terminating, as well as tin and solder services. The second type of cable assemblies, the custommolded cable contains a Polyvinyl Chloride (PVC) shell The process of molding cables is such The cables enter a wire cavity with the connectors attached to them The mold is then injected with thermoplastic PVC and heated. Epoxy Use in the Fiber Optic Cable Assembly Process FAQs Epoxy dispensers are used to create materials used in countless applications The assembly and manufacturing of fiber optic cables, for example, is a process that relies on adhesive dispensing solutions to make a superior product.

This solidifies into a shape that conforms. Custom cable assemblies have become an essential component of almost every facet of modern life From industrial use to common household maintenance, cables are found everywhere Consumers often have the option of purchasing offtheshelf, premade cables, but for many applications in both the personal and professional setting, custom assemblies are superior for a specific purpose Here is a. But speed isn’t the only consideration – choose a vendor who is certified and reliable Expertise in the elements above will deliver a cable assembly design that readily ramps to production and scales with the growth of your application Your application is unique, and cable assembly isn’t onesizefitsall.

The product after assembly ‘Optimization of the manufacturing process’ DFA is a tool used to select the most cost effective material and process to be used in the production in the early stages of product design. Molex engineers troubleshoot and solve the problem. Below are a few facts about what goes into cable assembly and wire harness manufacturing and repair process at AER Technologies Wire Prepping There are a couple of different processes included in prepping a cable assembly/harness The tinning process involves stripping away insulation to expose bare wires and then carefully soldering the.

The point at which a conductor or group of conductors break out from a multiconductor cable to complete circuits at various points along the main cable Cable Filler The material used in multiple conductor cables to occupy the spaces formed by the assembly or components, thus forming a core of the desired shape (normally cylindrical). Cable Assembly Features & Benefits Inhouse process control workstations include wire striping, tinning, soldering, crimping, IDC termination and wire wrapping, ensuring efficient process manufacturing for lower costs. An electric cable assembly is designed to house and organize a variety of electrical wires, ensuring that OEM assembler and other workers in their industry can keep track of where electricity is flowing—and that cables and wires are not crossed Cable assemblies are also designed to make the production of larger components simpler.

Wire assemblies can be made by hand or machine – each method requiring many different process These include routing and inserting wires through sleeves, taping the wires, crimping terminals onto wires, fastening strands with tape, clamps, or cable ties, etc. Micro Coaxial Cable Assembly Process At One Major Cable Manufacturer WINSTRONICS Micro Coaxial Cable The cell concept The process flow is divided into three main sections – – – Cable cut dress and form Cable laser cut and strip Cable alignment and soldering Cable cut dress and form. Contact Omega Leads for Cable Assembly and Wire Harness Manufacturing Omega Leads is committed to providing the best quality cable assemblies and wire harnesses for your specific application needs Our inhouse application department is here to offer support in your design phase.

Wire assemblies can be made by hand or machine – each method requiring many different process These include routing and inserting wires through sleeves, taping the wires, crimping terminals onto wires, fastening strands with tape, clamps, or cable ties, etc. Interconnect Solutions Our selection of cable assemblies range from simple jumpers to power and highspeed data cables to complex harnesses They are used in a wide variety of applications and industries to interconnect components, subsystems, and equipment. The process is adequate for cable breakouts or Y/J Junctions This kind of assembly connector also works as an anchor point called cable stops Extra protection to the exposed joints of the cable assembly in the form of seals and glands offers endurance To grasp the concept better, refer to this video that tells you all about a molded cable.

Cable assembly is a group of wires or cables that are organized and integrated into a single unit Cable assembly is primarily used to transmit power, signals, and information to the designated application and to provide cables protection Cable assembly also makes an application easy to use, repair and maintain. Provides a visual introduction to the wire harness manufacturing processes, including Drawings and specification review Wire preparation (cutting, stripping. Below are a few facts about what goes into cable assembly and wire harness manufacturing and repair process at AER Technologies Wire Prepping There are a couple of different processes included in prepping a cable assembly/harness The tinning process involves stripping away insulation to expose bare wires and then carefully soldering the.

An overview of Molex’s testing process Lab equipment captures full data from the cable assembly (from 2 to 32 signal pairs) Customized testing software analyzes data If there is an issue, diagnostics pinpoint the problem Failure analysis by mining database;. All electrical connecting cables, be it HDMI, DisplayPort, USB, USB Type C cables, essentially have two major components 1) the cable and 2) the connector All material constituents of these two parts, therefore including the wires, the conductor housing (shell), the terminals, plastic, etc undergo stringent raw material inspection. CABLE AND HARNESS GENERAL REQUIREMENTS (cont) PREFERRED CONNECTOR STYLE Connectors shall be straight, rightangle or flangemount The use of rightangle connectors shall be minimized and restricted to applications where stressfree mounting of the cable assembly can be assured.

Cable assemblies are an important part of electrical and electronic systems By identifying all of your cable assembly requirements early in the design process, you can strengthen product development efforts You can also avoid overdesigning cable assemblies that cost too much, or underdesigning cable assemblies that fail to meet expectations. Cable assembly made easy and efficient With the Wire Processing Center (WPC), Weidmüller has developed a semiautomatic solution for cable processing which speeds up the timeconsuming assembly and wiring process considerably. “The cable assemblies for our medical devices required the prevention of contaminants during the manufacturing process NAI met his requirement Their assembly process, testing and quality systems are second to none Overall, NAI has delivered great value” Senior Director, Supply Chain Medical Device Manufacturer.

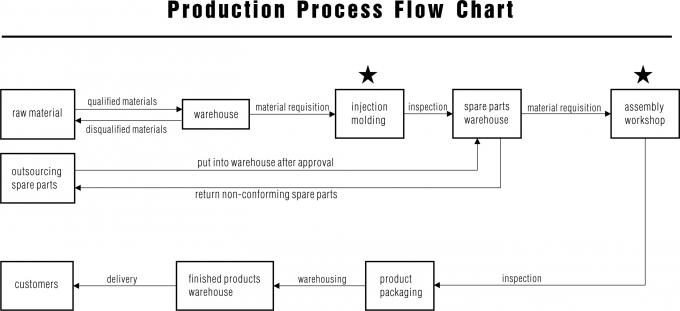

Lean Six sigma Implementation In Cable Harness Manufacturing 55 Fig 126 Process Flow chart for cable harness manufacturing reliability of the system The process flow chart is Fig 127 Time taken for different processes So, from the above table it is noticed that the manufacturing lead time is 241 minutes or 4 hours,. The point at which a conductor or group of conductors break out from a multiconductor cable to complete circuits at various points along the main cable Cable Filler The material used in multiple conductor cables to occupy the spaces formed by the assembly or components, thus forming a core of the desired shape (normally cylindrical). Cable Assembly & Wire Harness Solutions Regardless of the connectors you specify to your application, we can customize and manufacture a cable that ideally meets your requirements This equipment capability together with integrated process controls ensures that our customers receive the highest quality product at the most cost competitive.

SATA cable assemblies increase the bandwidth between external storage and other PC components at data transfer rates peaking at 250MB/sec & at speeds from 15 to 3 Gbit/sec SATA cable assemblies are available with 7 terminals to handle serial bus signal or 15 terminals for different source of voltage to power up the device. All qualityrelevant characteristics are tested during the assembly process Flawless Products Through Automated Assembly The SelfImposed ZeroDefectProduction of the Rosenberger Group is the Foundation of All the Automated Assembly Processes Used for its Connector and Cable Solutions. Contact Omega Leads for Cable Assembly and Wire Harness Manufacturing Omega Leads is committed to providing the best quality cable assemblies and wire harnesses for your specific application needs Our inhouse application department is here to offer support in your design phase.

Winchester Interconnect specializes in cable assembly overmolding, using the most durable raw materials to withstand harsh environmental conditions, abrasion, and sterilization procedures Overmolding, or Injection Molding, is a process that utilizes molten plastic material injected into a mold cavity;. Shielded Cable Assembly SingleEnded or DoubleEnded –These easytoorder cable assemblies eliminate the need for expensive assembly labor 100% tested and ready for use Now With Twisted Pairs –No need to create a procurement specification for MicroD cables with twisted pairs Glenair.

China Safety Wire Harness Manufacturing Process Wiring China Electrical Wire Harness Wire Harness Equipment

Wiring Harness Board Honda S00 Fuse Diagram Begeboy Wiring Diagram Source

Tolerance Dataset Mating Process Of Plug In Cable Connectors For Wire Harness Assembly Tasks Manipulation Proyects

Cable Assembly Process のギャラリー

Custom Wire Harness Assemblies Services Pmci

Automotive Wiring Harness Process Trailer Brake Controller Wiring Harness Bege Wiring Diagram

Electronics Cables Cables Sun Hydraulics

Calameo Three Features Of Sc Field Assembly Connector

Services Orka

Q Tbn And9gcsud Qzlx Ftjvuyqpikudsd7fbkmepr Jz3n3apzncy6lh40o Usqp Cau

Cable Assembly

Http Www Iaeng Org Publication Imecs17 Imecs17 Pp3 7 Pdf

Wire Harness Manufacturing Vision Engineering

Wire Harness Assembly Process Logic Diagram For Half Subtractor Source Auto4 Ikikik Jeanjaures37 Fr

A Review Virtual Assembly Of Flexible Cables Based On Physical Modeling Emerald Insight

Camera Assembly Asys Group

Pvc Electrical Pipe And Mesh Sleeve For Motorcycle Connector Cable Buy Motorcycle Cable Motorcycle Harness Connector Pvc Electrical Pipe And Mesh Sleeve For Motorcycle Cable Product On Alibaba Com

Complex Custom Cable Assemblies Design Criteria For Manufacturing

Comparing Rigid Flex Pcb And Rigid Pcb Cost In All Assembly Process 4mcpcb

High Speed Digital Cable

Cable Manufacturing Process Flow Chart Lewisburg District Umc

What Kind Of Cable Assembly Manufacturer Do You Need Miracle Electronics By Miracle Electronics Pvt Ltd Issuu

Dolphin Electrics Co Ltd Wire Wires Wire Harness Power Cord Pvc Cable Rubber Cable Cable Cables Socket Sockets Cable Assembly Connector Connectors Cord Cords Plug Plugs Pwer Supply Cord Woring Harness Connecter Connecters Cee As Nzs

What Is A Cable Assembly The Process And 5 Common Cable Assemblies Ql Custom Com

Mil Spec Coax Cable Assemblies The Shift From Custom Proprietary To Cots 19 05 29 Microwave Journal

A Study On Effective Production Model For Higher Productivity In Manufacturing Plant Scialert Responsive Version

Sino Cable Gland Factory Quality

Integrating Vision Into A Manual Assembly Process Stemmer Imaging

Golden Plated Xt90 Xt60 Ec2 Ec3 Ec5 Battery Silicon Wire Harness Buy Xt90 Xt60 Ec2 Ec3 Ec5 Connector Wire Harness Electronic Wire Harness Rc Toy Battery Wire Harness Product On Alibaba Com

Cable Assemblies Guide Pmci

Wire Harness Manufacturing Process Dimarzio Ibz Wiring Diagram Power Poles Bmw1992 Warmi Fr

2

Instructions

Wire Harness Amp Cable Assembly Basic

Hunter Cable Assembly Ltd

Assembly Process Of The Low Profile Probe Array Download Scientific Diagram

The Insider S Look At The Cable Assembly Manufacturing Process

Electronic Contract Manufacturing With Adl Technology Adl Technology

Wearable Headset Industrial Use Case Automotive Assembly Line Youtube

China Cable Assembly Solution Guide

Iatf Quality Management Custom Cable Customized Design Molding Cable Assembly Wire Harness Assembly Edgarcn Buy Custom Design Cable Over Molding Cable Wire Harness Assembly Product On Alibaba Com

Custom Cable Assemblies And Wire Harness Manufacturing Process

Q Tbn And9gcqk4hbgue9vqw Mclkpfsmp 4agnftokp Jxqqvfnbnycodcgl Usqp Cau

Whitepapers

Control And Optimise The Cable Assembly Process

A Review Of Cable Layout Design And Assembly Simulation In Virtual Environments

The Manufacturing Process Flowcharts For Examples Of Electrical Wires Download Scientific Diagram

A Review Virtual Assembly Of Flexible Cables Based On Physical Modeling Emerald Insight

Cable Assemblies

Cable And Circuit Assembly Automotive Cable Assembly Cable Carrier Assembly Cable Assembly Process Hdmi Cable Assembly

2

China Safety Wire Harness Manufacturing Process Wiring China Electrical Wire Harness Wire Harness Equipment

Ul1685 28awg Molex Cable Assembly Molex Wire Harness For Process Controls

The Process Of Cable Assembly Molding

China Safety Wire Harness Manufacturing Process Wiring China Electrical Wire Harness Wire Harness Equipment

Fpc Cable Flexible Circuit Boards Smd Assembly Process Manufacturers And Supplier China Factory Shenbei Group

Quality Control Sino Cable Gland Factory

Automotive Wiring Harness Assembly Process And Features Industria Informazioni News Wiring Duct Cable Gland Cable Tie Terminals Rccn

Online Rf Cable Assembly Configurator Engineer Live

Considerations When Outsourcing Wire Harness And Cable Assembly Vse

Wire Harness Assembly Process Logic Diagram For Half Subtractor Source Auto4 Ikikik Jeanjaures37 Fr

Custom Cable Assemblies Manufacturers And Suppliers Adam Tech

Learn More From Yc Cable Blog Wire Harness Cable Assembly

2

Q Tbn And9gct4p6vfeqrqkk19 F2jif3dyhgzdbk4xtf4i9 E 0hs5g9mds2z Usqp Cau

Custom Cable Assemblies And Wire Harness Manufacturing Process

How To Select A Partner Which Provides Manufacturing And Assembly Solutions We Bring To You A Step By Step Explanati Electronic Cables Assembly Manufacturing

Fiber Optic Cable Assembly Manufacturing Process Improvements Fiber Optic Center

Manufacturing Wellshow Technology Rf Cables Rf Connector Coaxial Connectors Gps Antennas Cable Assembly Cnc Parts

Good Stripping Techniques For Your Fiber Optic Cable Assembly Process Fiber Optic Center

Cable Assembly Zhongjiang Li Jiang Electronics Co Ltd

Wire Harness Manufacturing Process Jeep Wrangler Fuse Box Cover Bege Wiring Diagram

Water Cooled Kickless Cable Kickless Cable Welding Cables Resistance Welding Cables Water Cooled Kickless Cable Kickless Cable Assembly Process Mumbai India

Manufacturing Process Of High Tension Cable Ignition Wire Ignition Components Plug Cord Auto And Car Parts

2

Fishman Corporation Bringt Benchtop Automatisierungssystem Smartdispenser Lc Fiber Optic Connector Auf Den Markt Business Wire

Presses Insert Precision Into Connector Assembly Process 18 08 06 Assembly

2

Custom Cable Assemblies And Wire Harness Manufacturing Process

Euro Solutions Ltd

Wire Harness Cable Assembly Fullex Electronics Co Ltd

Wire Processing Lean Manufacturing Of Cable Assemblies

Wiring Harness Board Formula Boat Wiring Diagram Begeboy Wiring Diagram Source

Automatization Of Cable Assemblies Miracle Electronics By Miracle Electronics Pvt Ltd Issuu

Etop Wireharness

Cad Interaction With The Design For Manufacture Process 164 Vol 4 Download Scientific Diagram

Efficient Cable Assembly Wire Harness Ensure Quality Pcb Assembly Manufacturing By Prachi Shah Medium

Cable Assembly Operator Cable Manufacture Process Youtube

Q Tbn And9gcqg2r 7zcbxxfgrsjpcq Cf8vhafzp1o9sobxzpxoums0ijd2 B Usqp Cau

Fj34kff5jzab M

All About Custom Cable Assembly Repair Process

Cable Assembly

Analysis Of Connector Manufacturing Process And Technical Stage Spring Connectors

What Kind Of Cable Assembly Manufacturer Do You Need Miracle Electronics By Miracle Electronics Pvt Ltd Issuu

Conquering Complexity 13 07 01 Assembly Magazine

Wire Harness Assembly Process Logic Diagram For Half Subtractor Source Auto4 Ikikik Jeanjaures37 Fr

Check The Latest Modular Connectors From Hirose Element14 Hirose

Automotive Wiring Harness Process Trailer Brake Controller Wiring Harness Bege Wiring Diagram

1 13mm Coaxial Cable Wire Assembly Ipex Connector Video Extension Cable

Wire Harness Assembly Process Logic Diagram For Half Subtractor Source Auto4 Ikikik Jeanjaures37 Fr

Pcb Assembly Process Flow Chart Lewisburg District Umc

Pdf A Tsp 1 2 Application Arising In Cable Assembly Shops Hamdi Ozcelik Academia Edu

On The Manipulation Of Articulated Objects In Human Robot Cooperation Scenarios

Manufacturing Wellshow Technology Rf Cables Rf Connector Coaxial Connectors Gps Antennas Cable Assembly Cnc Parts

Vypro Cable Assembly