Dc And Rf Sputtering

The latter study showed much improved properties when compared to other reports on TMDC systems Also, better control of the coating properties could be achieved while working with separate.

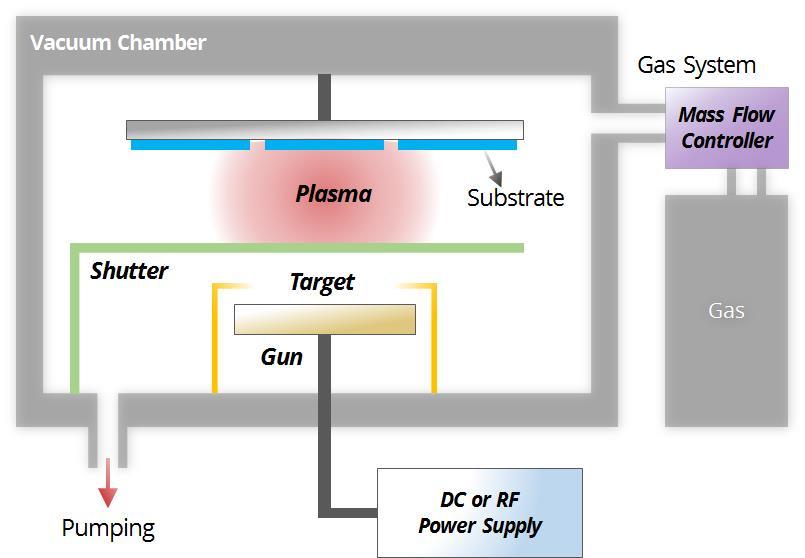

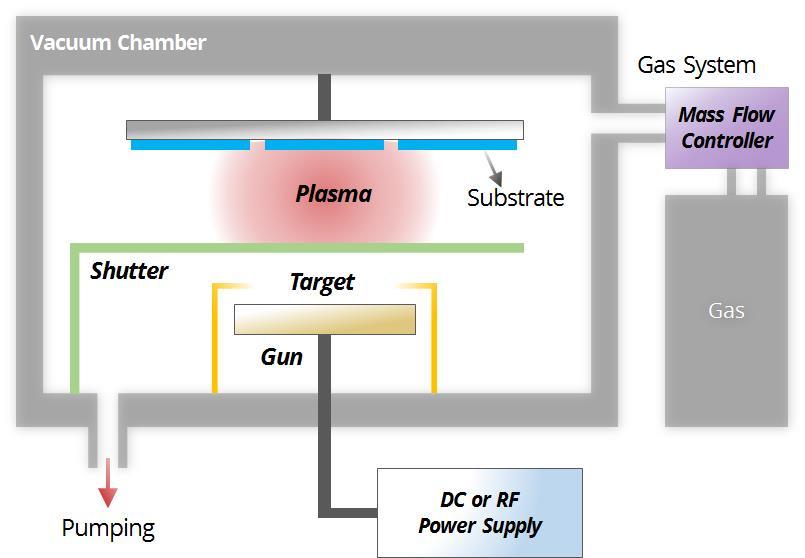

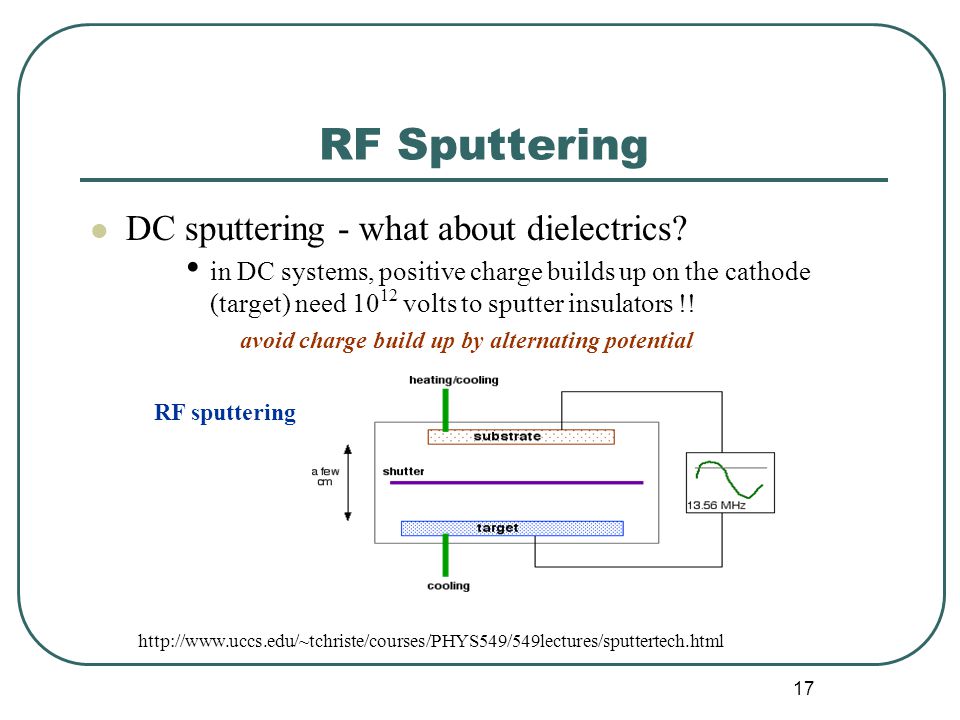

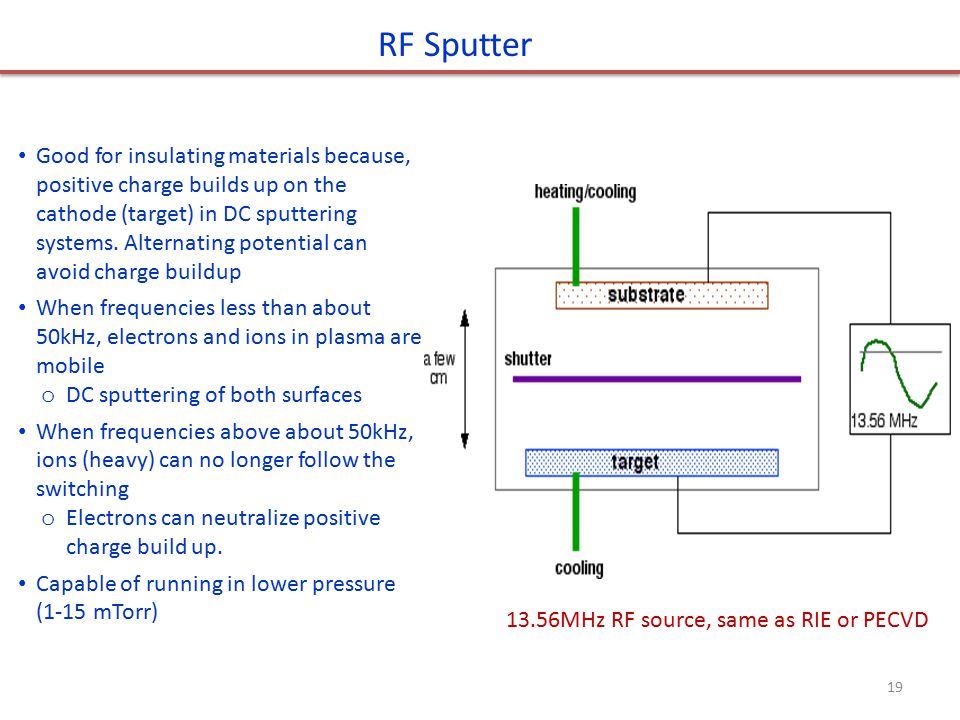

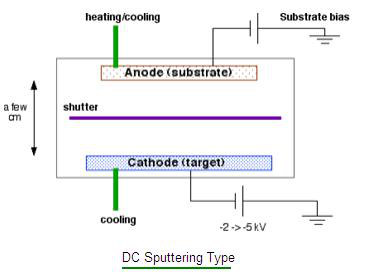

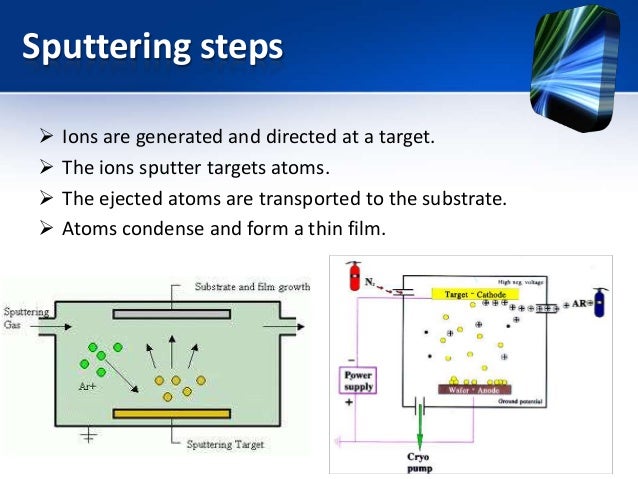

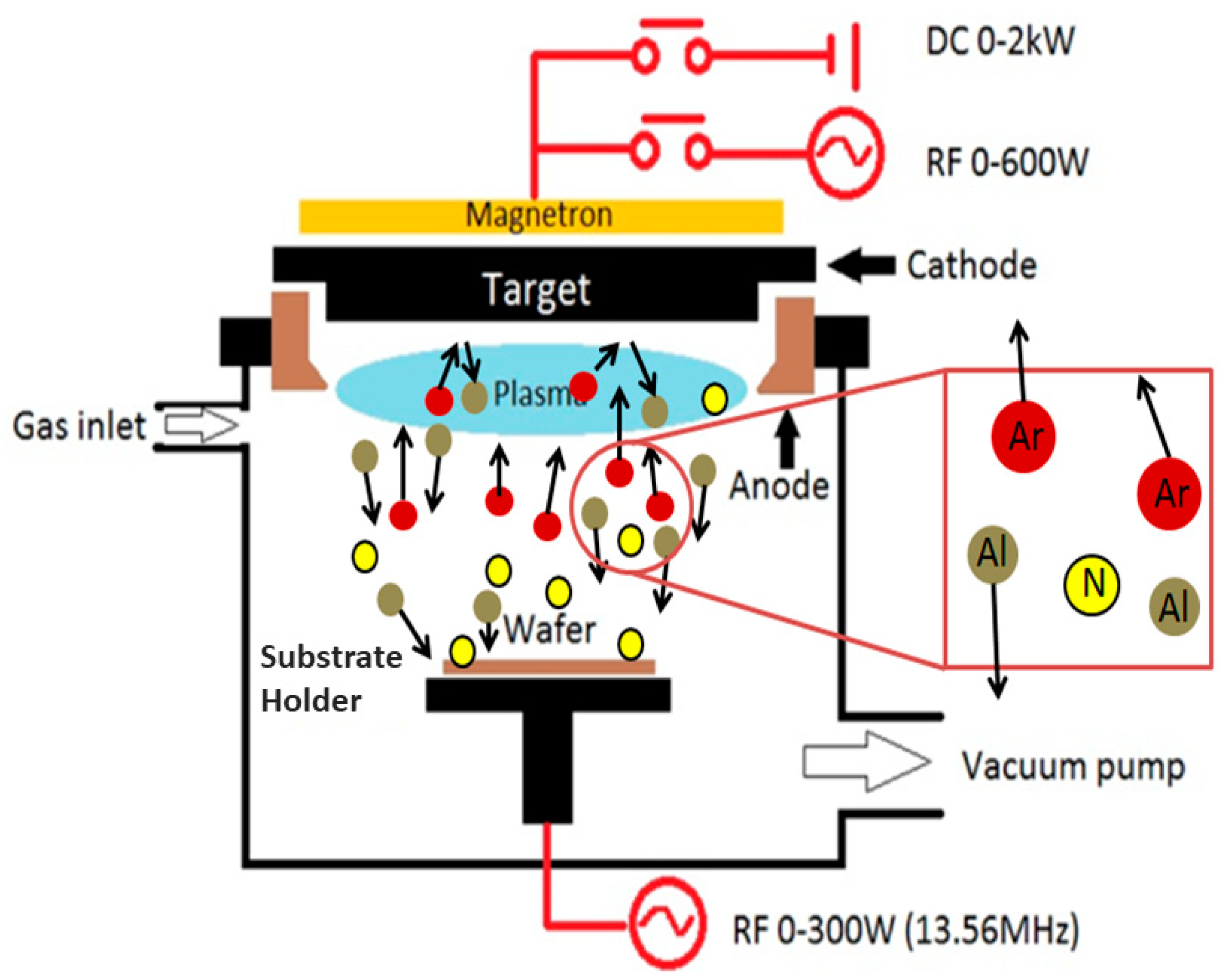

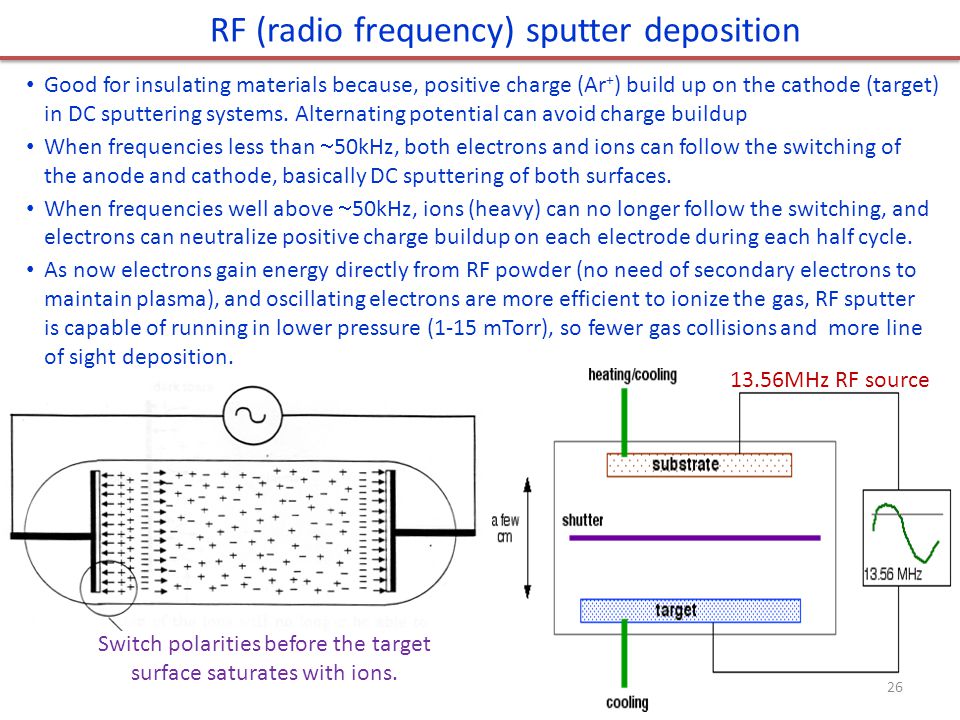

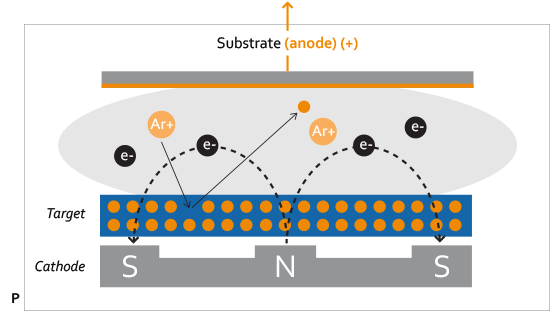

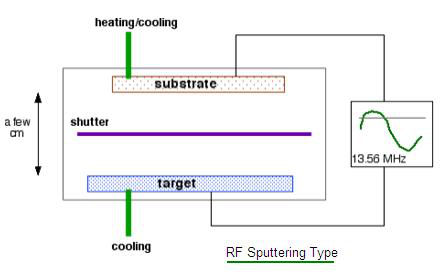

Dc and rf sputtering. Substrate temperature up to 1000°C. RF plasmas tend to fill the chamber as opposed to DC plasmas which are confined to the cathode • Normally both the target and substrate should sputter This can be overcome by making the target area small compared to the substrate • While any type of film can be RF sputtered, deposition rates are still low •. RF Radio Frequency Sputtering Power RF Power can be used with all materials, but generally finds most use in depositing films from dielectric target materials The deposition rate (driven by the relative duty cycle) when compared to DC is generally quite low and the electron flux (due to the mobility difference of electrons and ions in a plasma.

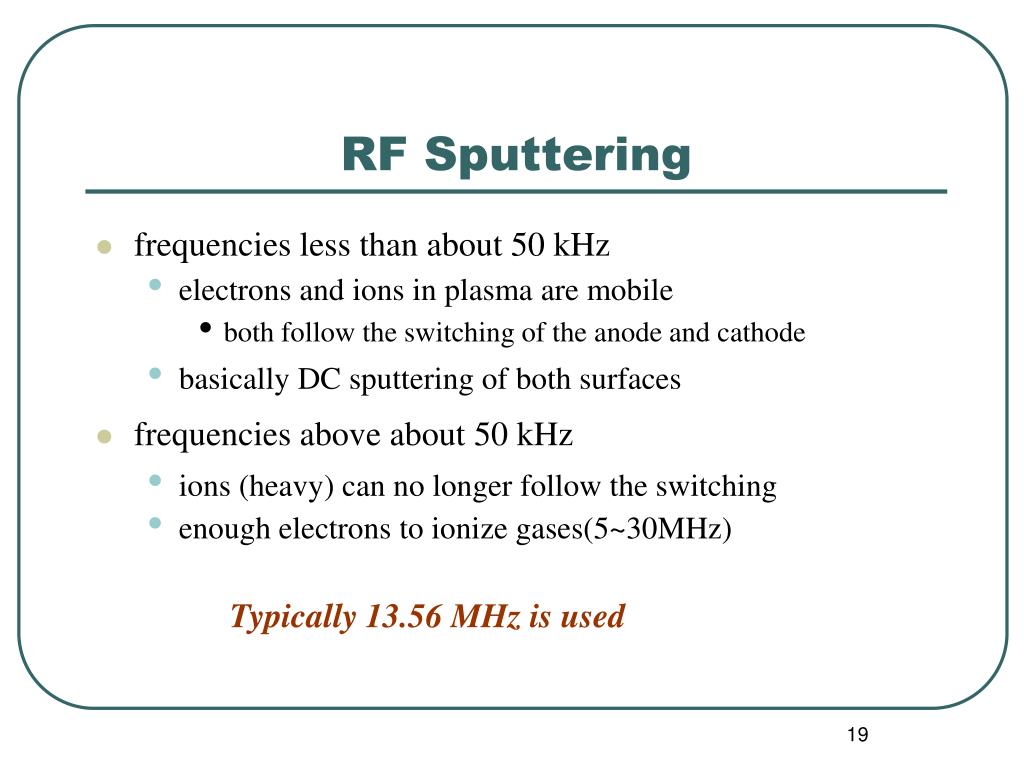

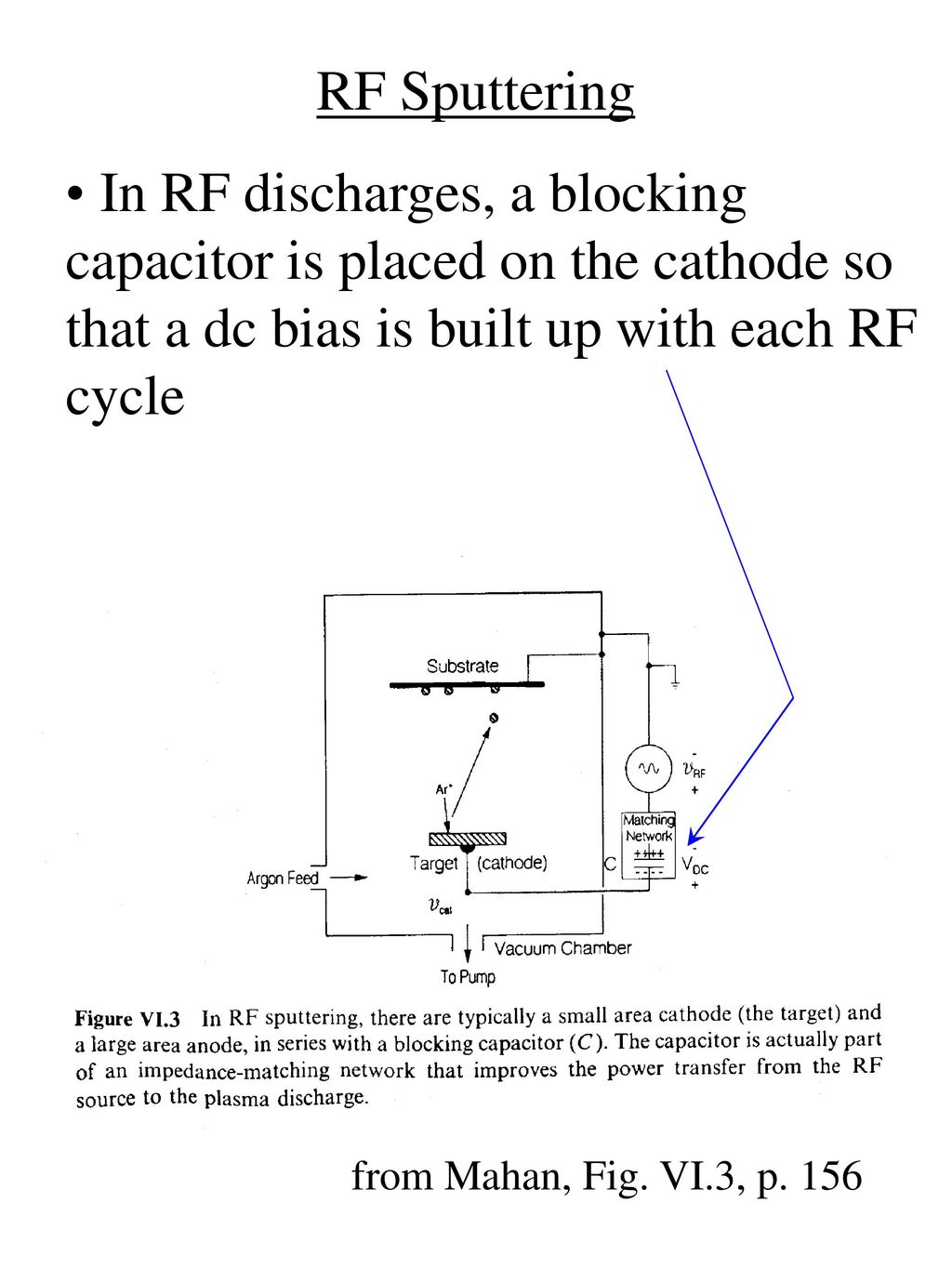

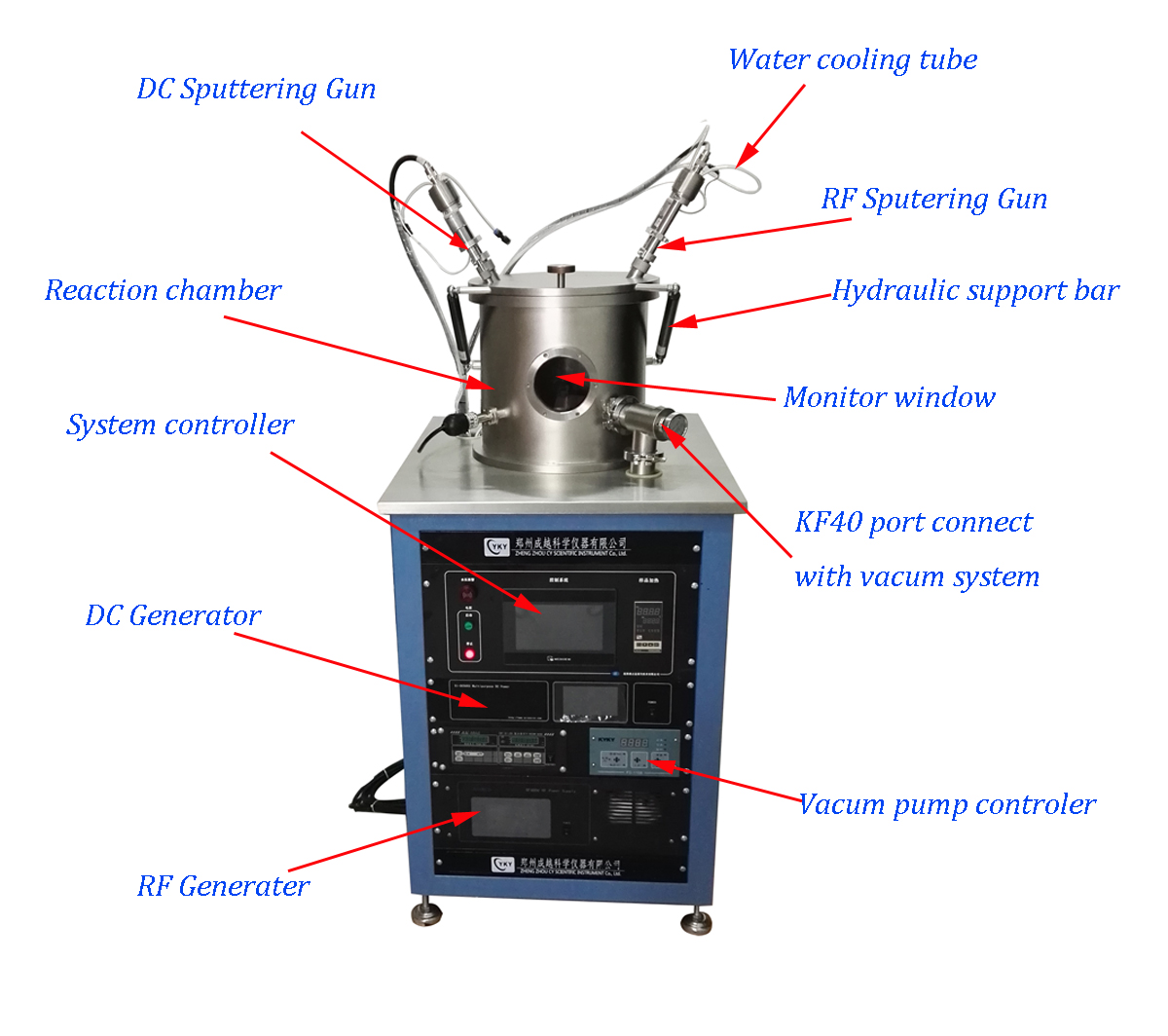

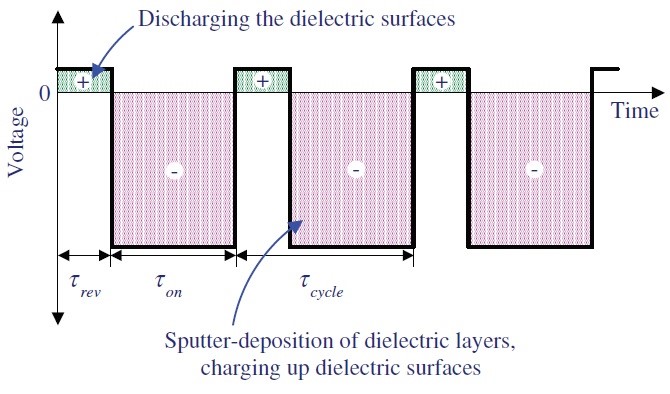

Rectangular or circular DC and RF cathodes;. RF & DC Sputtering System Scientific & Analytical Instruments offers standard and customized RF/DC Magnetron Sputtering System in different size as per customer requirement to produce quality, thin and homogenous film coatings. 2 RF sputtering In radio frequency sputtering, a highfrequency alternating field is applied instead of the DC electric field The necessary highfrequency voltage source is connected in series with a capacitor and the plasma The capacitor serves to separate the DC component and to keep the plasma electrically neutral.

RF & DC Sputtering System Scientific & Analytical Instruments offers standard and customized RF/DC Magnetron Sputtering System in different size as per customer requirement to produce quality, thin and homogenous film coatings SAI Sputtering systems are versatile for thin film coatings in Research, Educational Institutions, Semiconductor. Since RF sputtering uses radio waves instead of a direct electron current, it has different requirements and effects on the sputtering systemFor instance, DC systems require between 2,000 and 5,000 volts, while RF systems require upwards of 10 12 volts to achieve the same rate of sputter deposition This is largely because DC systems involve the direct bombardment of the gas plasma atoms by. Comparison of DC Sputtering, Magnetron Sputtering and Sputtering Coating Sputtering is one of the main technologies for the preparation of thin film materialsIt uses the ions generated by the ion source to accelerate the aggregation in vacuum, forming a highspeed ion beam flow, bombarding the solid surface, and the ion and the atoms on the solid surface exchange kinetic energy, so that the.

341 Sputtering (DC/RF/Reactive RF) Besides DC magnetron sputtering 16, RF magnetron sputtering 13 and reactive RF sputtering 32 are reported to be other efficient methods to synthesize uniform, stable, highly crystalline and stoichiometric films yielding reproducible and endurable RRAM devices In these processes, ion beam is bombarded. Mentions difference between RF sputtering and DC sputtering What is SputteringSputtering is highly versatile vacuum coating system which is used for deposition of various coating materials Plasma gas is used ti knock atoms out of the target. As with DC Sputtering, RF Sputtering runs an energetic wave through an inert gas in a vacuum chamber which becomes ionized The target material or cathode which is to become the thin film coating is bombarded by these high energy ions sputtering off atoms as a fine spray covering the substrate to be coated.

Magnetron sputtering includes many types, such as direct current (DC) magnetron sputtering and radio frequency (RF) magnetron sputtering, each has a different working principle and application objects The main advantage of RF magnetron sputtering over DC magnetron sputtering is that it does not require the target as an electrode be. Reactive and nonreactive sputtering;. DC/RF Magnetron Switch Box PVD Products can provide RF/DC Switch boxes that allow the end user to run a magnetron with either RF or DC power via computer control Fully compatible with all vendor RF tuners and DC power supplies We have built DC power supplies for voltages of 300 Watts through kWatts, and pulsed DC supplies for 1 kW through.

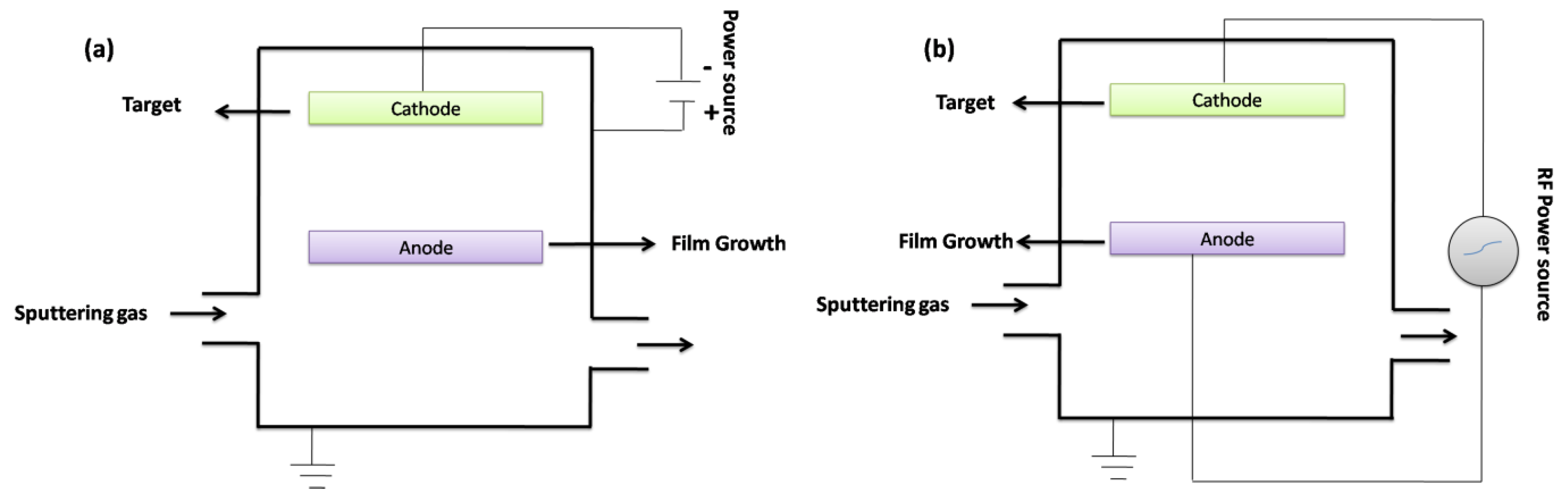

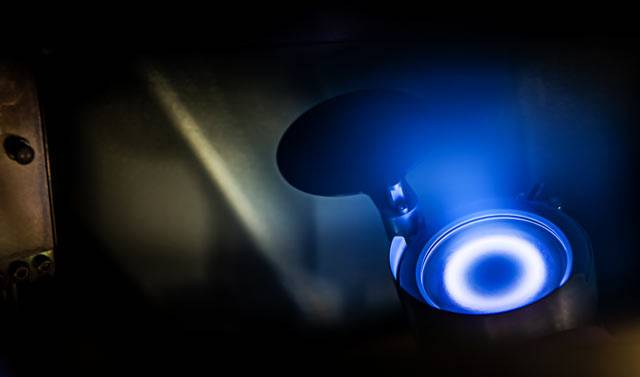

It mentions RF sputtering advantages and RF sputtering disadvantages The figure1 below depicts RF sputtering system Silent features of the system are as follows • RF Source frequency 1356 MHz • RF peak to peak voltage 1000 V • Electron densities 10 9 to 10 11 Cm3 • Chamber pressure 05 to 10 mTorr There are two processes. Rf sputtering can be used with a magnetic field in balanced and unbalanced configurations to obtain a result similar to dclike diode discharge In fig 2 the different configurations of dc and rf sputtering are shown a) b) Fig 2 Sputtering configurations a) dc sputtering, b) rf sputtering. Static or dynamic deposition, planetary and double planetary rotation, oscillation;.

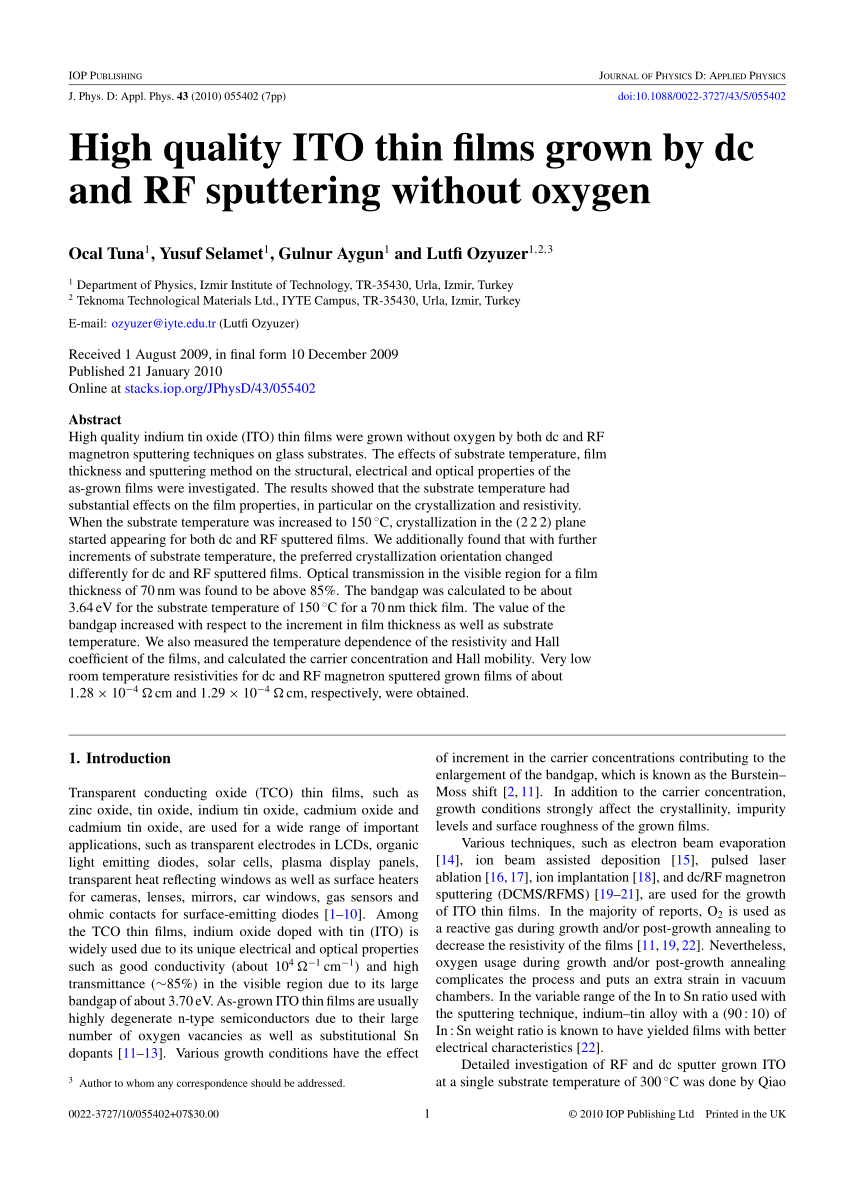

The effect of annealing on the physical properties of DC and RF sputtered ITO thin films has been investigated Two series of samples were deposited onto glass substrates, the first one consists of several In 2 O 3Sn (ITO) prepared by DC reactive sputtering with different partial pressure of oxygen (ppo);. RF sputtering DC sputtering에서는 target이 산화물이나 절연체일 경우 sputtering되지 않는다 이러한 단점은 RF sputtering함으로써 해결될 수 있으며 특히 낮은 Ar 압력에서도 plasma가 유지될 수 있다. RFsputtering offers advantages over DC;.

The latter study showed much improved properties when compared to other reports on TMDC systems Also, better control of the coating properties could be achieved while working with separate. Previously, our research group deposited Mo–Se–C coatings by RF sputtering of a composite target ,25,38, and DC sputtering of 2 separate targets ;. RF bias on substrates prior to and during deposition;.

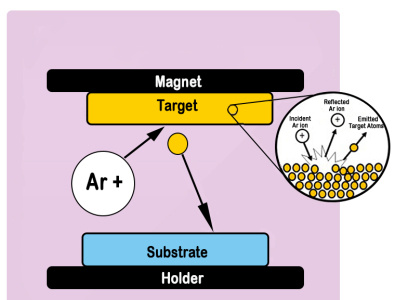

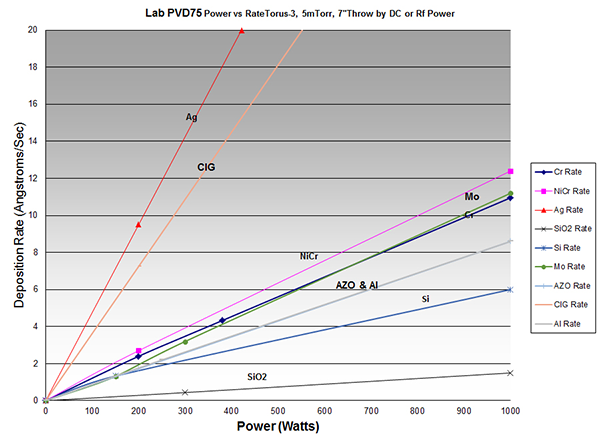

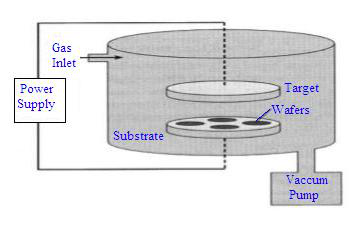

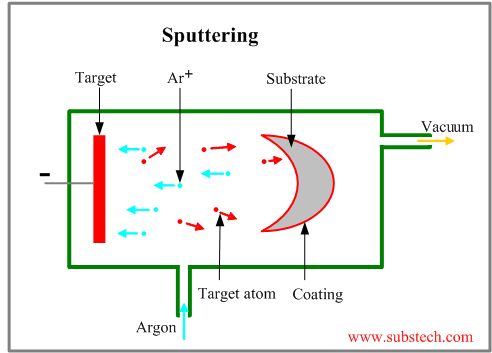

FISSION – RF & DC SPUTTERING Deposition Technique Sputter deposition is a widelyused technique for the deposition of thin films A plasma is ignited above a negativelybiased ‘target’ which has the effect that ions are drawn from the plasma and accelerated towards the target material On impact, the argon ions eject atoms/molecules. Abstract Chromium (Cr) films were deposited on plain carbon steel sheets by dc and rf magnetron sputtering as well as by electroplating Effects of dc or rf sputtering power on the deposition rate and properties such as, hardness, adhesion strength, surface roughness and corrosion resistance of the Cr films were investigated. Abstract Chromium (Cr) films were deposited on plain carbon steel sheets by dc and rf magnetron sputtering as well as by electroplating Effects of dc or rf sputtering power on the deposition rate and properties such as, hardness, adhesion strength, surface roughness and corrosion resistance of the Cr films were investigated.

DC/RF Magnetron Switch Box PVD Products can provide RF/DC Switch boxes that allow the end user to run a magnetron with either RF or DC power via computer control Fully compatible with all vendor RF tuners and DC power supplies We have built DC power supplies for voltages of 300 Watts through kWatts, and pulsed DC supplies for 1 kW through. In particular sputtering of an electrically insulating target become possible Magnetron The magnetron is the desing of highdepositionrare sputtering sources The magnetron is a magnetically assisted discharge As in the DC and RF sputtering arrangements there is a perpendicular (to the target surface. This calculation allows a semiquantitative estimate of the rf voltage developed at the target for a given value of rf input power.

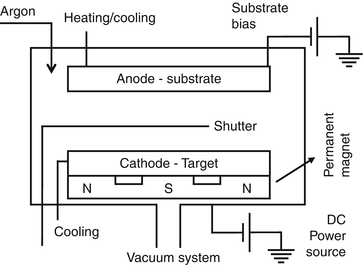

The above illustration describes a generic manifestation of a magnetron sputtering source DC, pulsed DC, AC and RF power supplies may be used, depending upon target material, if reactive sputtering is desired and other factors A permanent magnet structure is located behind a target serving as a deposition source. Magnetron sputtering includes many types, such as direct current (DC) magnetron sputtering and radio frequency (RF) magnetron sputtering, each has a different working principle and application objects The main advantage of RF magnetron sputtering over DC magnetron sputtering is that it does not require the target as an electrode be. Ablation 16,17, ion implantation 18, and dc/RF magnetron sputtering (DCMS/RFMS) 19–21, are used for the growth of ITO thin films In the majority of reports, O 2 is used as a reactive gas during growth and/or postgrowth annealing to decrease the resistivity of the films 11,19,22 Nevertheless,.

RF/ DC sputtering System(Hind Hivac Systems) Introduction Sputter deposition is a physical vapor deposition process for depositing thin films, sputtering means ejecting material from a target and depositing it on a substrate such as a silicon wafer The target is the source material. 1 Sputter deposition processes D Depla 1, S Mahieu 1, JE Greene 2 1 Ghent University, Department of Solid State Sciences, Krijgslaan 281 (S1), 9000 Ghent, Belgium 2 Materials Science and Physics Departments and the Frederick Seitz Materials Research Laboratory, University of Illinois, Urbana, Illinois , USA Sputter deposition is a widely used technique to deposit thin films on substrates. These proven DC power supplies are ideally suited for coating processes where reliability & performance are critical The KJLC DC Series power supplies range in power levels from 1kW to 1kW They are intended primarily for DC magnetron sputtering and as DC bias sources They are compact and over 90% efficient.

RF plasmas tend to fill the chamber as opposed to DC plasmas which are confined to the cathode • Normally both the target and substrate should sputter This can be overcome by making the target area small compared to the substrate • While any type of film can be RF sputtered, deposition rates are still low •. 2 RF sputtering In radio frequency sputtering, a highfrequency alternating field is applied instead of the DC electric field The necessary highfrequency voltage source is connected in series with a capacitor and the plasma The capacitor serves to separate the DC component and to keep the plasma electrically neutral. Sputtering itself contains multiple subtypes, each with its own applicability Among the many are direct current (DC), radio frequency (RF), midfrequency (MF), pulsed DC and HiPIMS We design our coating process to meet your specific needs and have the experience and equipment to execute any of these.

FISSION – RF & DC SPUTTERING Deposition Technique Sputter deposition is a widelyused technique for the deposition of thin films A plasma is ignited above a negativelybiased ‘target’ which has the effect that ions are drawn from the plasma and accelerated towards the target material On impact, the argon ions eject atoms/molecules. RF and DC Magnetron Sputtering Unit Submitted by smpuricsr on Tue, 11 1448 RF and DC Magnetron Sputtering Unit Reference ME//033/RAMK/RF DC SPUTTER File Tender document Annexure 1 EMD CPP Proof Opening Date 01/12/ Closing Date 21/12/ Address. Radio frequency (RF) sputtering is a technique that is used to create thin films, such as those found in the computer and semiconductor industry Like direct current (DC) sputtering, this technique involves running an energetic wave through an inert gas to create positive ions.

RF Radio Frequency Sputtering Power RF Power can be used with all materials, but generally finds most use in depositing films from dielectric target materials The deposition rate (driven by the relative duty cycle) when compared to DC is generally quite low and the electron flux (due to the mobility difference of electrons and ions in a plasma. In the second one, the ITO samples were done by RF sputtering with different RF powers. Comparison of DC Sputtering, Magnetron Sputtering and Sputtering Coating Sputtering is one of the main technologies for the preparation of thin film materialsIt uses the ions generated by the ion source to accelerate the aggregation in vacuum, forming a highspeed ion beam flow, bombarding the solid surface, and the ion and the atoms on the solid surface exchange kinetic energy, so that the.

Magnetron sputtering includes many types, such as direct current (DC) magnetron sputtering and radio frequency (RF) magnetron sputtering, each has a different working principle and application objects The main advantage of RF magnetron sputtering over DC magnetron sputtering is that it does not require the target as an electrode be. DC (direct current) sputtering is a material deposition process used to coat substrate structures with thin films of different materials The process involves bombarding a donor material with ionized gas molecules, causing a displacement of donor atoms. Clusters for confocal systems, cosputtering;.

I've searched online and it seems that one way of improving step coverage for sputtering is to apply a bias voltage to the substrate We are currently doing DC magnetron sputtering However our. Comparison of DC Sputtering, Magnetron Sputtering and Sputtering Coating Sputtering is one of the main technologies for the preparation of thin film materialsIt uses the ions generated by the ion source to accelerate the aggregation in vacuum, forming a highspeed ion beam flow, bombarding the solid surface, and the ion and the atoms on the solid surface exchange kinetic energy, so that the. An improved sputtering method for sputter deposition from nonconducting metal oxide, ceramic, and ferroelectric targets is disclosed Enhancements in deposition rate and composition control have been demonstrated using a pulsed DC sputtering method using a power supply in the frequency range of 100 to 250 KHz and a low frequency RF sputtering method using a power supply in the range of 0 to.

In this video I am discussing about the sputtering (DCRF) for thin film deposition. DC/RF Magnetron Switch Box PVD Products can provide RF/DC Switch boxes that allow the end user to run a magnetron with either RF or DC power via computer control Fully compatible with all vendor RF tuners and DC power supplies We have built DC power supplies for voltages of 300 Watts through kWatts, and pulsed DC supplies for 1 kW through. Rf sputtering can be used with a magnetic field in balanced and unbalanced configurations to obtain a result similar to dclike diode discharge In fig 2 the different configurations of dc and rf sputtering are shown a) b) Fig 2 Sputtering configurations a) dc sputtering, b) rf sputtering.

Sputtered using DC and RF sputtering in an Edwards Auto 500 sputtering system This system has both a DC and RF magnetron sources with identical geometrical arrangement Generally, glass or ptype Sih100i substrates have been used The targetsubstrate distance of 110mm and background pressure of 12 10 2 mbar were kept constant during all trials. Figure 1 RF Sputtering Configuration For RF sputtering, a highfrequency generator is used generating electromagnetic power in the MHzRegion (typical 1356 MHz) The output voltage and current capabilities of these generators are limited, so they need to work on a defined load impedance of 50 W. Ablation 16,17, ion implantation 18, and dc/RF magnetron sputtering (DCMS/RFMS) 19–21, are used for the growth of ITO thin films In the majority of reports, O 2 is used as a reactive gas during growth and/or postgrowth annealing to decrease the resistivity of the films 11,19,22 Nevertheless,.

RF plasmas tend to fill the chamber as opposed to DC plasmas which are confined to the cathode • Normally both the target and substrate should sputter This can be overcome by making the target area small compared to the substrate • While any type of film can be RF sputtered, deposition rates are still low •. Rf sputtering can be used with a magnetic field in balanced and unbalanced configurations to obtain a result similar to dclike diode discharge In fig 2 the different configurations of dc and rf sputtering are shown a) b) Fig 2 Sputtering configurations a) dc sputtering, b) rf sputtering. DC (direct current) sputtering is a material deposition process used to coat substrate structures with thin films of different materials The process involves bombarding a donor material with ionized gas molecules, causing a displacement of donor atoms.

The dc bias developed at the substrate is explained and related to the resputtering energy In addition, an approximate calculation is presented for the ion density in the plasma;. RF Sputtering DC sputtering cannot be used if the target material is electrically nonconductive or has low electrical conductivity As described in the previous sections, in the sputtering process, positive ions accelerate towards the target and cause the target atoms to be removed If the electrical conductivity of the target material is low. Sputter deposition can be carried out using DC power supplies for metals and RF power supplies which can sputter metals and insulating targets such as silica Although more expensive, RF sputtering can be used to deposit almost any material.

The above illustration describes a generic manifestation of a magnetron sputtering source DC, pulsed DC, AC and RF power supplies may be used, depending upon target material, if reactive sputtering is desired and other factors A permanent magnet structure is located behind a target serving as a deposition source. The main difference is that the power used in RF sputtering is AC, while that in DC sputtering is DC Basically, during DC sputtering, the working gas will be ionized As a result, many positive. The above illustration describes a generic manifestation of a magnetron sputtering source DC, pulsed DC, AC and RF power supplies may be used, depending upon target material, if reactive sputtering is desired and other factors A permanent magnet structure is located behind a target serving as a deposition source.

Previously, our research group deposited Mo–Se–C coatings by RF sputtering of a composite target ,25,38, and DC sputtering of 2 separate targets ;. The work reports a comparison between RF and DC sputtering of MoSe2 coatings with carbon and provides a guideline to optimize the composition, morphology, structure, and mechanical properties Low stoichiometry, low crystallinity, low hardness and incongruencies involving the reported microstructure have limited the applicability of TMDC. The RFsputtered film will be smoother and have better packing density RF also deposits the film at about % of the DC rateIf you want to sputter using DC, pulsed DC, or AC, you must have a conductive (or semiconductive) target I always check the conductivity of a target by placing my ohm meter probes anywhere on the target surface.

Edwards Auto 306 Dc And Rf Sputter Coater Berkeley Microlab

Ppt Sputtering Processes For Thin Film Deposition Powerpoint Presentation Id

Technical Research Centre Trc

Dc And Rf Sputtering のギャラリー

Objectives Template

Schematic Diagrams Of A Dc Sputtering And B Rf Sputtering Ohring Download Scientific Diagram

Optimization Of Sputtering Parameters For The Deposition Of Low Resistivity Indium Tin Oxide Thin Films

Impact Of Plasma Electron Flux On Plasma Damage Free Sputtering Of Ultrathin Tin Doped Indium Oxide Contact Layer On P Gan For Ingan Gan Light Emitting Diodes Son 18 Advanced Science Wiley Online

Www Physlab Org Wp Content Uploads 16 04 Murtaza Presentaion Pdf

What Is Rf Sputtering

1 High Vacuum Magnetron Sputter Source Hvmss Spc 1 Ld

What Is Rf Sputtering

Rf Dc Sputtering Source For 4 X 0 25 Target St40 Demaco

Q Tbn And9gcshlif7nuxioujxgd7nrra9kid5wmlqnopfe1n0rszeenv6uenq Usqp Cau

Rf Magnetron Sputtering Ppt

Rf Sputtering Of Polycrystalline 100 002 And 101 Oriented Aln On An Epitaxial 3c Sic 100 On Si 100 Substrate Journal Of Vacuum Science Technology B Vol 32 No 6

Rf Sputtering Principles Ifn Trento

Rf Dc Low Profile Sputtering Source For 2 X 0 12 Magnetic Target St Mm Lp Demaco

Graphic Of Dc And Rf Sputtering 44 Download Scientific Diagram

Rf Sputtering Principles Ifn Trento

Dc Rf Dual Head High Vacuum 2 Magnetron Plasma Sputtering Coater Vtc 600 2hd

Catalysts Free Full Text A Review On The Pathways Of The Improved Structural Characteristics And Photocatalytic Performance Of Titanium Dioxide Tio2 Thin Films Fabricated By The Magnetron Sputtering Technique Html

Sputtering Configurations A Dc Sputtering B Rf Sputtering Download Scientific Diagram

Advances In Rf Sputtering Aultimut

1 High Vacuum Magnetron Sputter Source Hvmss Spc 1 Ld

1

Own Industrial Rf Dc Sputtering System Rs Piece S Scientific Analytical Instruments Id

Diamond Like Carbon Thin Films With High Density And Low Internal Stress Deposited By Coupling Dc Rf Magnetron Sputtering Sciencedirect

Iran Nano Product Iran Nano Product Products Dc Rf Magnetron Sputtering System Omega Series

What Is Dc Sputtering

Structural Optical And Electrical Studies Of Dc Rf Magnetron Co Sputtered Cu In Ag Doped Sns Thin Films For Photovoltaic Applications Solar Energy X Mol

Sputtering Processes For Thin Film Deposition Ppt Video Online Download

D C Sputtering Springerlink

Schematic Of The Aja Orion 1800f Rf Dc Sputter Deposition System Used Download Scientific Diagram

Ppt Sputtering And Cvd Pvd Technology Powerpoint Presentation Free Download Id

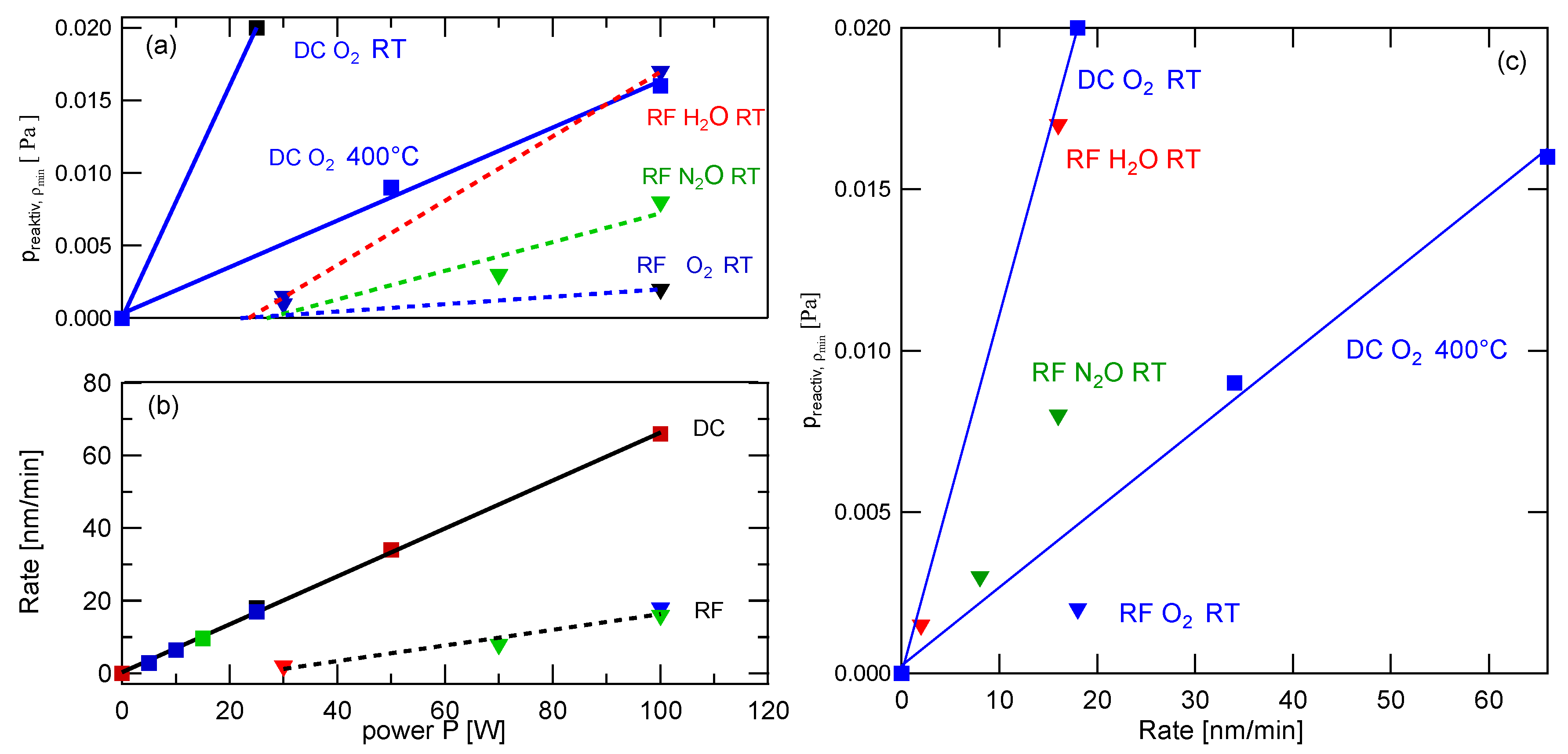

Rf Superimposed Dc And Pulsed Dc Sputtering For Deposition Of Transparent Conductive Oxides Sciencedirect

Dc Sputtering Disadvantage 1 Low Secondary Electron Yield Ppt Download

Q Tbn And9gcsuoy4slu00tinn60ktxryqn8jfpdq Qdxrfhkhw3obrfwwmsye Usqp Cau

Tailoring Of Tio2 Film Microstructure By Pulsed Dc And Rf Magnetron Co Sputtering Sciencedirect

Sputter Deposition Wikipedia

Magnetron Sputtering An Overview Sciencedirect Topics

Figure 1 From Surface Properties And Biocompatibility Of Nanostructured Tio2 Film Deposited By Rf Magnetron Sputtering Semantic Scholar

Thin Film Deposition Key Performance Indices Ppt Video Online Download

Dc Sputtering

Figure 7 In Situ And Ex Situ Studies Of Molybdenum Thin Films Deposited By Rf And Dc Magnetron Sputtering As A Back Contact For Cigs Solar Cells

Sputter Deposition An Overview Sciencedirect Topics

Pvd Designs Themes Templates And Downloadable Graphic Elements On Dribbble

Dc Sputtering Vs Rf Sputtering The Comparison Of Dc Sputtering And Rf Sputtering

Diamond Like Carbon Thin Films With High Density And Low Internal Stress Deposited By Coupling Dc Rf Magnetron Sputtering Sciencedirect

Sputtering Power Induced Physical Property Variation Of Nickel Oxide Films By Radio Frequency Magnetron Sputtering

A A Schematic Illustration Of The Rf Dc Sputtering Chamber And Cutoff Download Scientific Diagram

Figure 39 3 Schematic Of Rf Sputtering Chamber

Pdf High Quality Ito Thin Films Grown By Dc And Rf Sputtering Without Oxygen

Sputtering Process

Pdf Optimized Scratch Adhesion For Tisin Coatings Deposited By A Combination Of Dc And Rf Sputtering Masjuki Haji Hassan Academia Edu

Schematic Diagram Of A Rf Dc Magnetron Sputtering System And B Download Scientific Diagram

Www Physlab Org Wp Content Uploads 16 04 Murtaza Presentaion Pdf

Sensors Free Full Text Reactive Sputtering Of Aluminum Nitride 002 Thin Films For Piezoelectric Applications A Review Html

Pdf Comparative Study Of Ito Layers Deposited By Dc And Rf Magnetron Sputtering At Room Temperature

1 High Vacuum Magnetron Sputter Source Hvmss Spc 1 Ld

Reactive Sputtering An Overview Sciencedirect Topics

Sputtering Aultimut

The Schematic Diagram Of Dc Magnetron Sputtering Download Scientific Diagram

Chapter 9 Thin Film Deposition Ppt Download

Kurt J Lesker Company Combinatorial Magnetron Sputtering Advances With New Tools And New Predictive Techniques Vacuum Science Is Our Business

Plasma Acceleration Using A Radio Frequency Self Bias Effect Physics Of Plasmas Vol 22 No 6

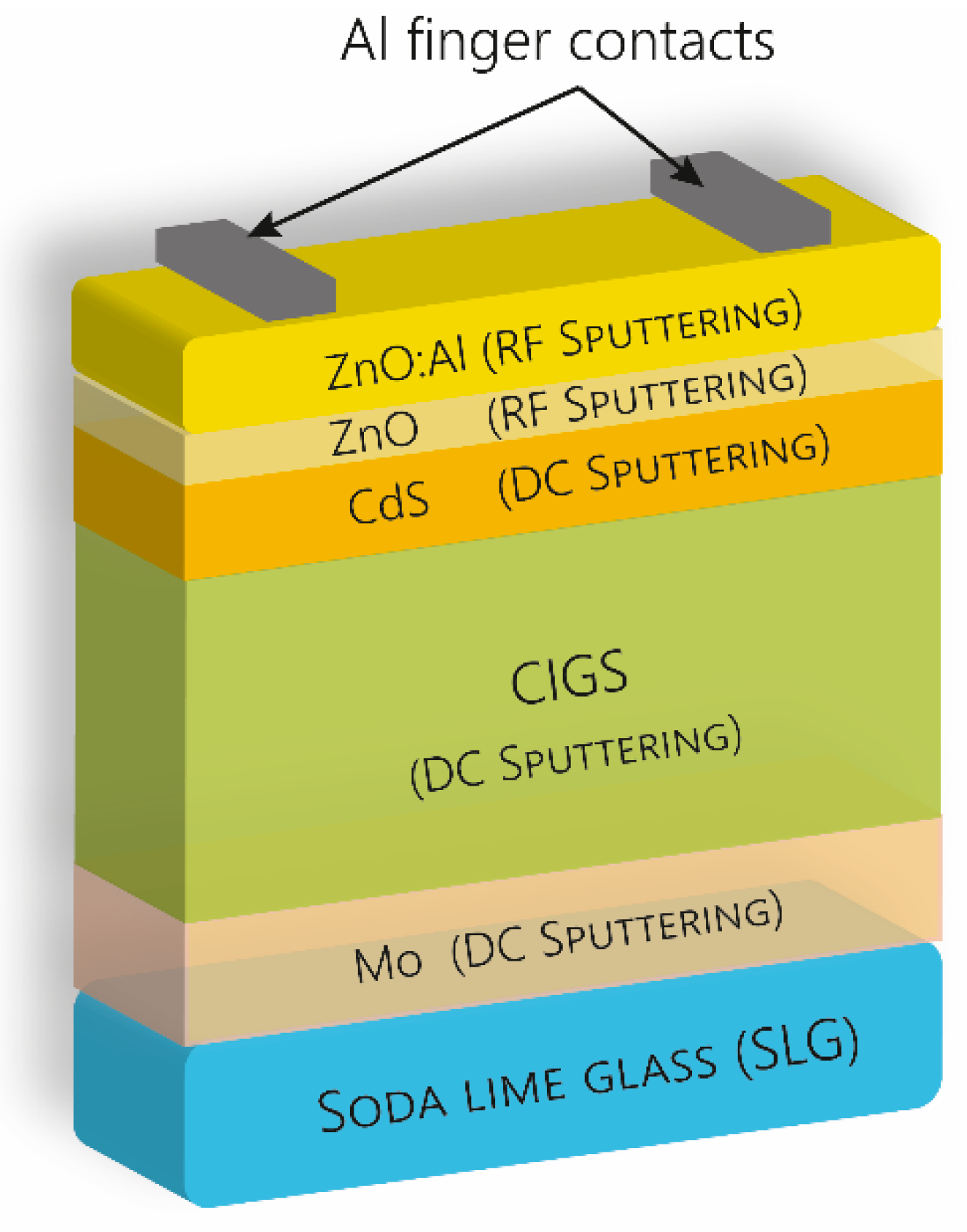

Coatings Free Full Text Rf Dc Magnetron Sputtering Deposition Of Thin Layers For Solar Cell Fabrication Html

Raman Spectra Of Slg After Dc Sputtering Of 4 Nm Cofe A And 2 Nm Al Download Scientific Diagram

Sputtering Type An Overview Sciencedirect Topics

Figure 1 From Investigations On Properties Of Zno Al Films Prepared By Rf Dc Co Sputtering Semantic Scholar

Fission Rf Dc Sputtering Korvus Technology

3 Heads Compact 1 Rf Plasma Magnetron Sputtering Coater With Dc Magnetron Sputtering Option Vtc 3rf

Q Tbn And9gcsuoy4slu00tinn60ktxryqn8jfpdq Qdxrfhkhw3obrfwwmsye Usqp Cau

Introduction To Microelectronic Fabrication Processes

Coatings Free Full Text Electrical And Optical Properties Of Amorphous Sno2 Ta Films Prepared By Dc And Rf Magnetron Sputtering A Systematic Study Of The Influence Of The Type Of The Reactive

Http Www Jkps Or Kr Journal Download Pdf Php Spage 511 Volume 40 Number 3

Rf Dc Switch Boxes For Thin Film Deposition And Plasma Processes

Rf Sputtering Principles Ifn Trento

Scientific Analytical Instruments Rf Dc Sputtering System

Dc Sputtering Vs Rf Sputtering The Comparison Of Dc Sputtering And Rf Sputtering

Impact Of Plasma Electron Flux On Plasma Damage Free Sputtering Of Ultrathin Tin Doped Indium Oxide Contact Layer On P Gan For Ingan Gan Light Emitting Diodes Son 18 Advanced Science Wiley Online

Rf Sputtering Principles Ifn Trento

Dc Rf Sputtering Dc Rf Sputtering Suppliers And Manufacturers At Alibaba Com

High Rate Sputtering Deposition Of Silicon Oxide Thin Films From New Sio2 Si Target Composition Journal Of Vacuum Science Technology A Vol 27 No 4

Automatic Single Phase Rf Dc Sputtering Unit Rs Unit Hydro Pneo Vac Technologies Id

Magnetron Sputtering Deposition Systems Denton Vacuum

Pulsed Dc Magnetron Sputtering Dc Sputtering Process Vaccoat

Sputtering Process

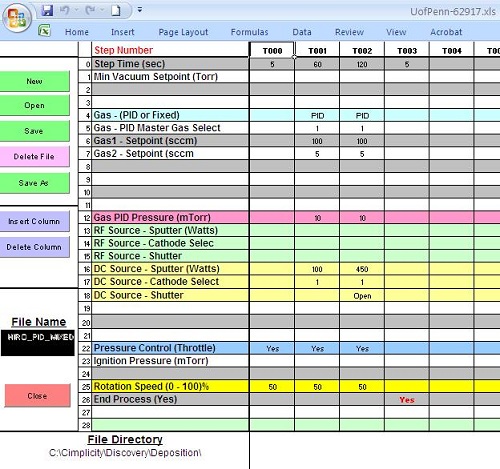

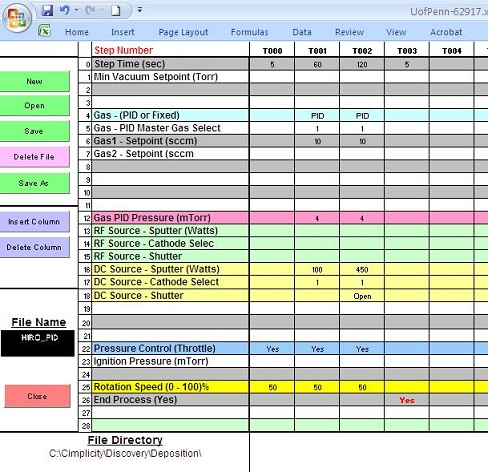

Explorer14 Recipes

Self Organizing Plasma Behavior In Rf Magnetron Sputtering Discharges Journal Of Applied Physics Vol 125 No

Magnetron Plasma Sputtering Coater

China 1 Magnetron Sputtering Source With Flexible Head For Diy Rf Dc Sputtering Coater China Magnetron Sputtering Source Magnetron Sputtering Cathode

Explorer14 Recipes

Research Center For Magnetic And Spintronic Materials

Pulsed Dc Magnetron Sputtering Dc Sputtering Process Vaccoat

A Comparison Of The Mechanical Properties Of Rf And Dc Sputter Deposited Cr Thin Films Scientific Net

Residual Stress Of As Deposited Niti Films Versus Rf Dc Sputtering Download Scientific Diagram

Dc Sputtering Vs Rf Sputtering The Comparison Of Dc Sputtering And Rf Sputtering

Impact Of Plasma Electron Flux On Plasma Damage Free Sputtering Of Ultrathin Tin Doped Indium Oxide Contact Layer On P Gan For Ingan Gan Light Emitting Diodes Son 18 Advanced Science Wiley Online

Rf Sputtering Principles Ifn Trento

Http Www E Asct Org Journal Download Pdf Php Spage 41 Volume 24 Number 2

Comparison In Formation Optical Properties And Applicability Of Dc Magnetron And Rf Sputtered Aluminum Oxide Films Sciencedirect

Faq Vaccoat

Sputtering Substech

Sputtering Power Induced Physical Property Variation Of Nickel Oxide Films By Radio Frequency Magnetron Sputtering