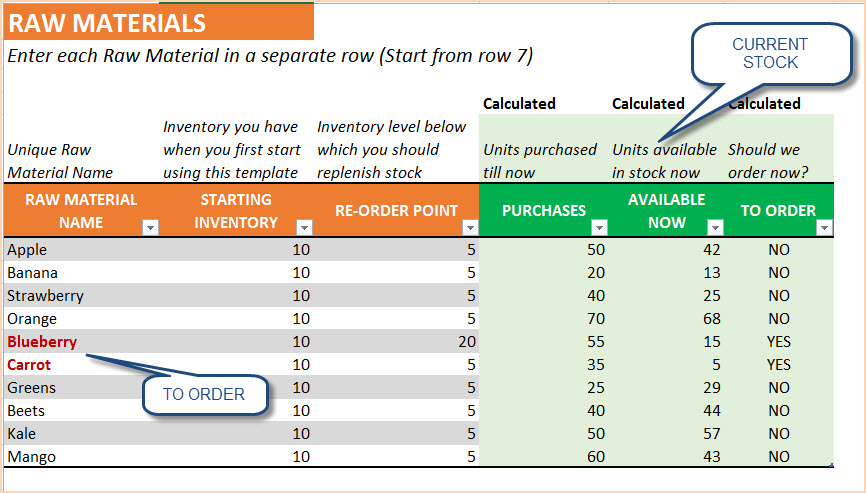

Raw Material Stock Formula

Tracking inventory raw materials The formula would recognize that there are 7 pieces that are 1348" long that can be used to make 7 of the 16 12" frames, then realize that the remaining 9 pieces can be made out of the " bar Same idea with the drywall piece the formula should calculate how many of the 8 18"*48" panels can be cut.

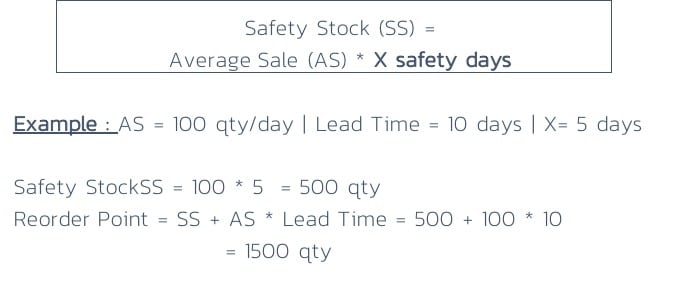

Raw material stock formula. The answer is properly calculated Component Safety Stock (CSS) Syllabus 1 Rationale behind Component Safety Stock (CSS) 2. Understanding Inventory Turnover Inventory is the account of all the goods a company has in its stock, including raw materials, workinprogress materials, and finished goods that will. So if this type of situation arises and in that instance, if your inventory has got safety stock, then you’ve no idea how much money will be saved.

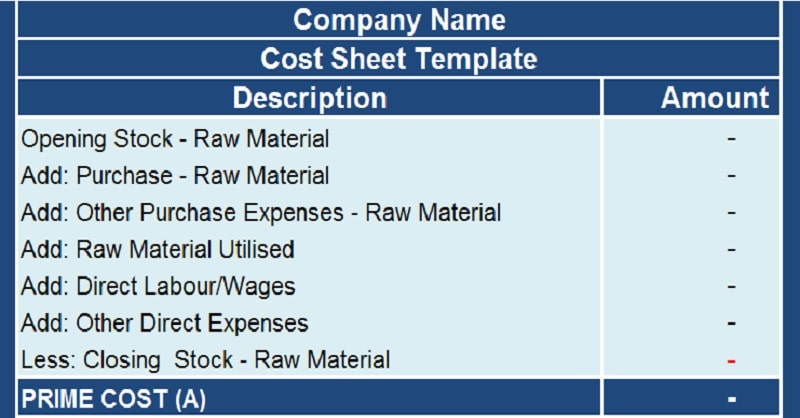

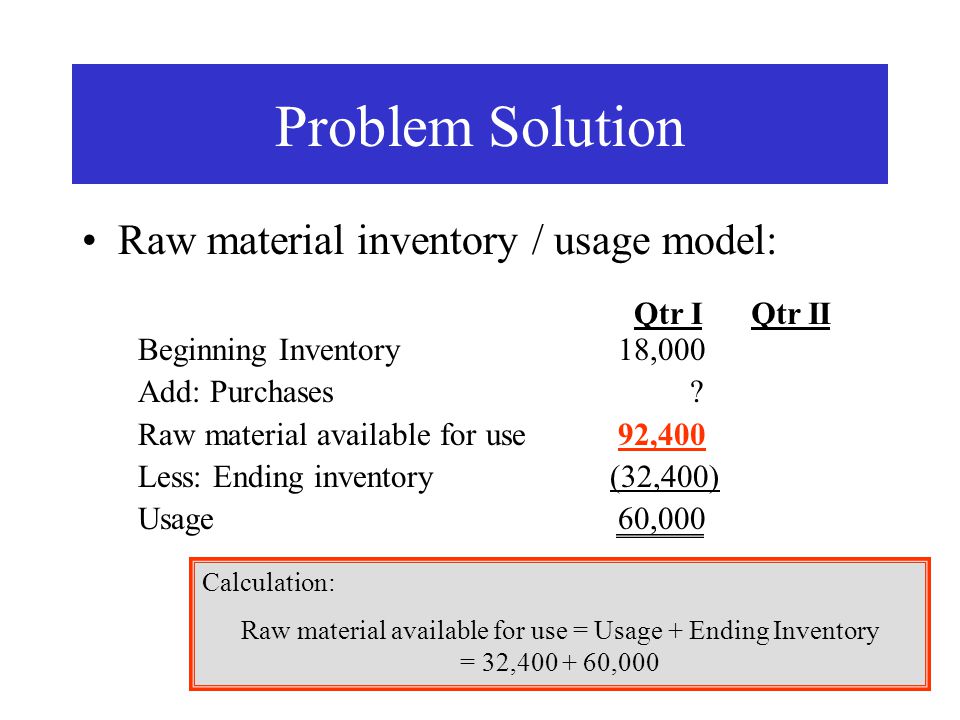

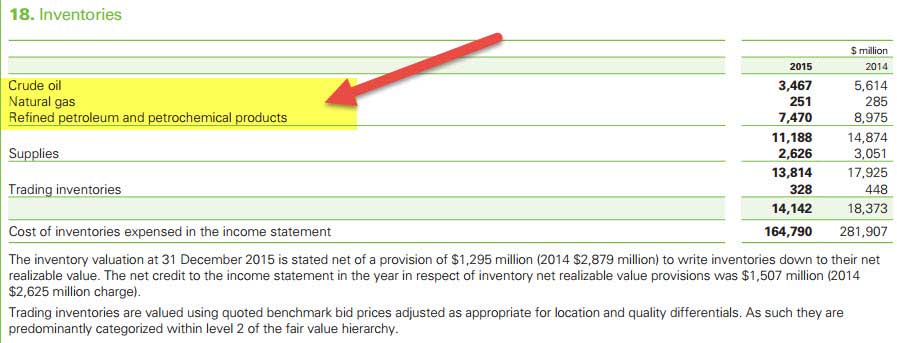

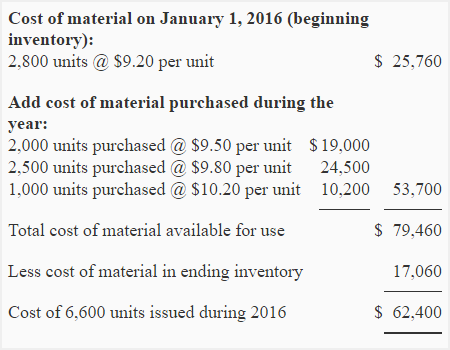

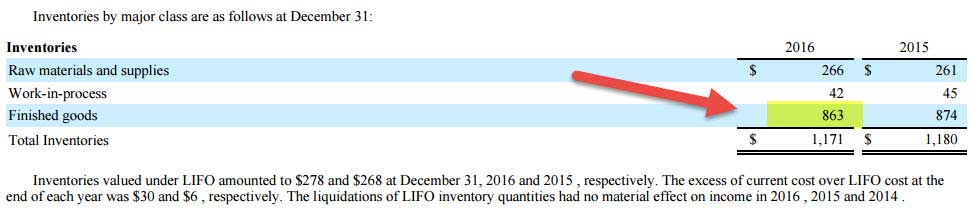

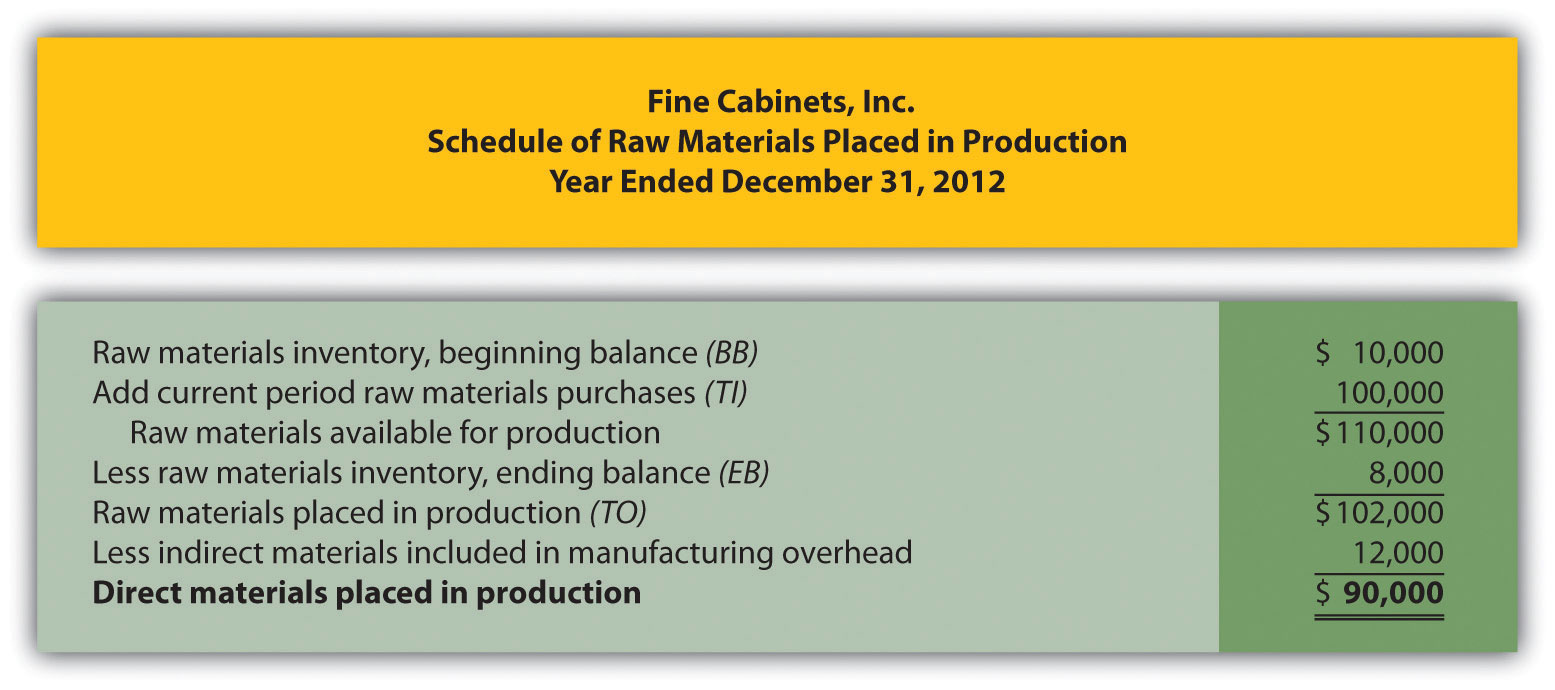

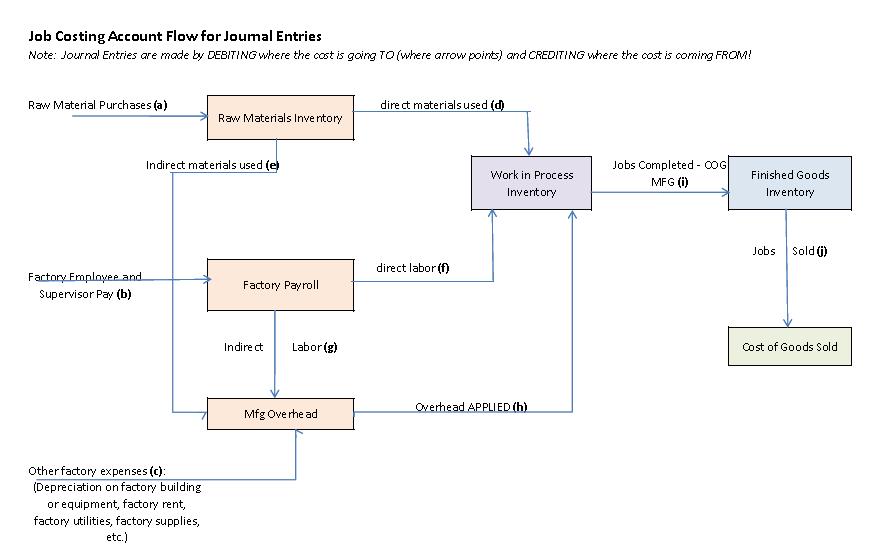

The raw materials inventory formula says that when you purchase raw materials, you debit your raw materials inventory asset account and credit accounts payable If you use up $100 of materials, you'd credit $100 to the raw materials account and debit $100 to works in progress or finished goods. For calculating yield of finished goods (actuals) , the formula is = Actual voulme (Qty) of Production divided by actual volume (Qty) of Raw materials consumed Now, coming to Percentage yield Percentage yield = Actual Yield divided by Standard yield Posted 7 years ago by HS VEDANTA DESHIKA. Raw Material Stock Account Credit Goods Return Account In the first case above, cash is received in return of goods In the second case, defective goods are exchanged with quality goods That is why, we debited our stock account Both entries are correct for return of purchased items Option 2 Debit Cash/Creditor Account.

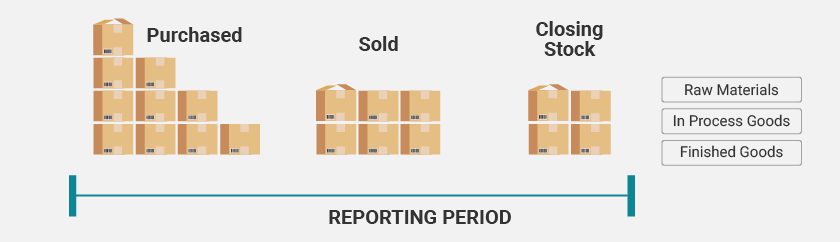

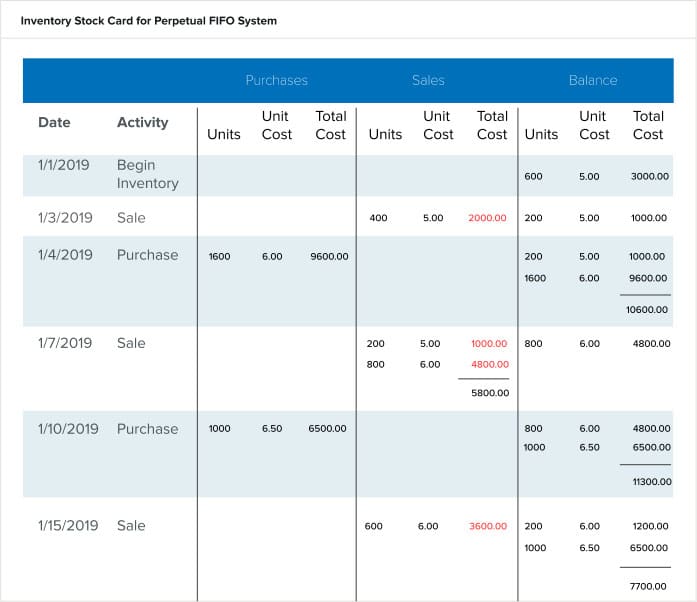

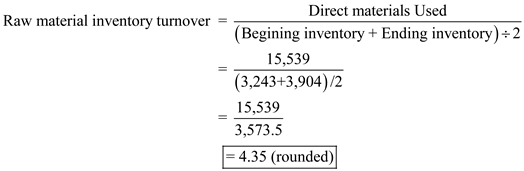

A bill of materials is an extensive list of raw materials, components, and instructions required to construct, manufacture, or repair a product or service. Once you have those numbers, you can calculate raw material inventory turnover by dividing the actual value of raw materials used by the raw materials inventory balance For example, if during the fiscal year raw materials amounting to $1 million were used, and the ending raw materials balance was $0,000, the raw material turnover ratio would equal $1 million divided by $0,000, or 50. Here, the closing stock on a given date is 22 Nos This will be carried forwarded to the next period or the next day as an opening balance With this understanding, you can arrive at the closing stock formula as below Closing stock = (Opening Stock Inward) Outward Opening stock is the unsold stock brought forwarded previous period.

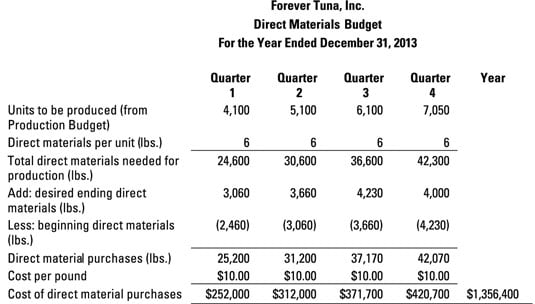

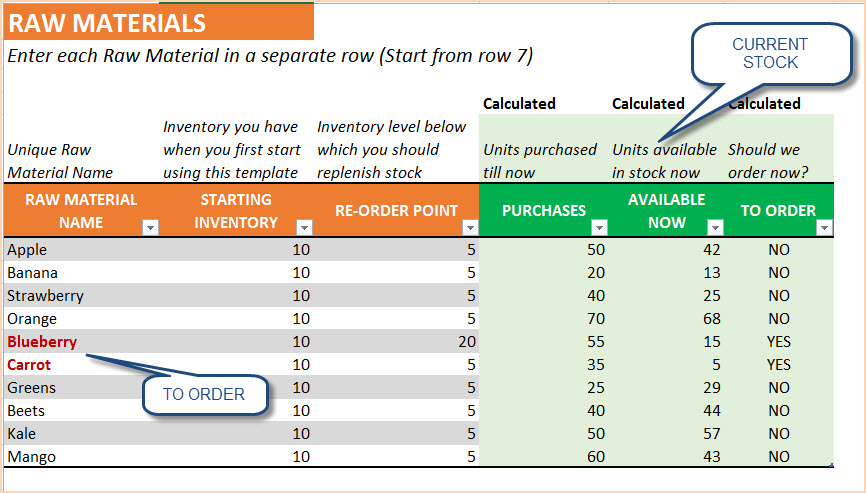

To monitor stock and identify slow moving inventory or that is not converting, stock ageing analysis reports are made The most common stock ageing analysis involve determining the age of product on the basis of data of purchase and particular date ie today’s date or any other date Following is the stock ageing analysis based on today’s. The bill of materials (BOM) quantity is 1, and the production quantity is 110 The formula for the consumption is From series (Quantity) = Consumption Because the production quantity is 110, it falls into the "From 100 series" Therefore, the quantity is. Formula The formulas used to calculate the minimum level of stock are given below Minimum Level of Inventory = (Maximum usage × Maximum lead time) – (Average usage × Average lead time) Or Minimum Level of inventory = Reorder level – (Average usage × Average lead time) Both the formulas are equivalent and produce the same result.

Finish Goods,Raw Material Consupmtion Formula This query is Resolved Report Abuse Follow Query Ask a Query Sushil Shinde Sushil Shinde 29 March 10 For Raw material consumption = Opening stock of R/M Purchase of R/M Closing stock of R/M For Finished Goods= Opening Stock Production closing stock Message likes 2 times. It lies in “Inventory Category” you must manage daily stock for reporting, otherwise, it’s difficult to manage bulk stock with particular date and time Mostly business especially product development warehouses specially design some template or software for managing. Compute the opening stock of raw material from the details given below Raw material purchased $ 37,000 Transport Inwards $7,000 Closing Stock $5,000 Raw material consumed $ 50,000.

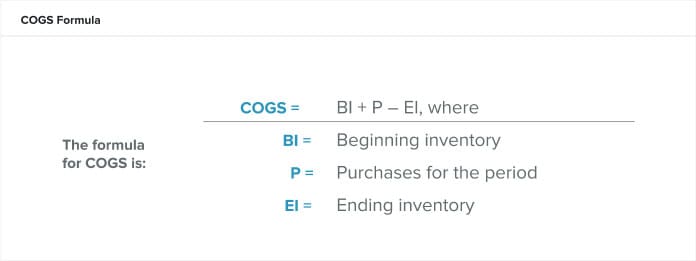

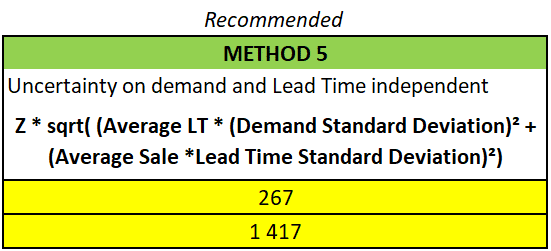

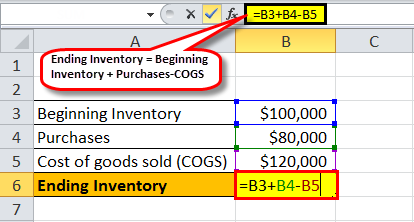

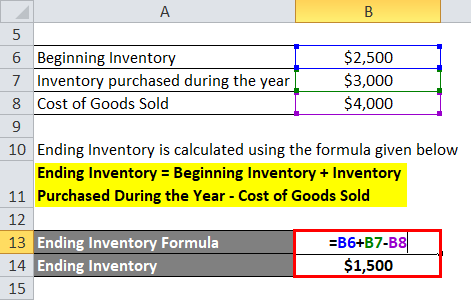

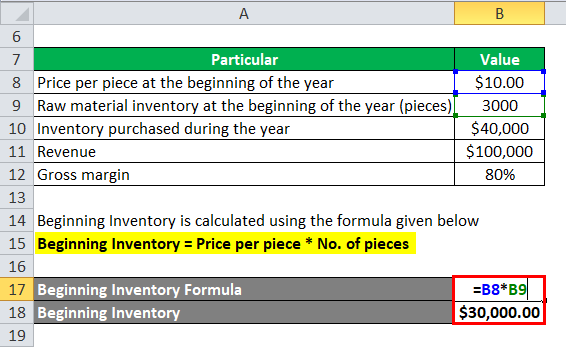

Safety stocks prevent stock outs when there is a high variation in demand and supply But what if the prices of the raw material whose product you sell sharply increases?. So if this type of situation arises and in that instance, if your inventory has got safety stock, then you’ve no idea how much money will be saved. The formula for this is as follows Ending Inventory = Beginning Balance Purchases – Cost of Goods Sold Higher sales (and thus higher cost of goods sold) leads to draining the inventory account The conceptual explanation for this is that raw materials, workinprogress, and finished goods (current assets) are turned into revenue.

Average Stock Level can also be calculated by the formula Minimum Stock Level ½ of Reorder Quantity ADVERTISEMENTS A = 0 ½ x 300 = 350 units B = 150 ½ x 500 = 400 units Illustration 2 If the minimum stock level and average stock level of raw material A are 4,000 and 9000 units respectively, find out its reorder quantity. 7 Raw Materials Stocks with Material Dividends With a robust dividend, longterm investors have a lot to like about this key materials stock Just remember, however, that size isn't always a. The formula of this safety stock (maximum sale x maximum lead time) – (average sale x average lead time) Taking the previous data, this gives you a safety stock of 427 For the order point, it is always the same formula Safety stock average sale (or average forecast) x average lead time This gives us here 1578.

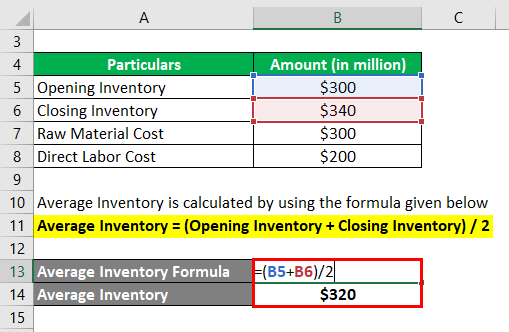

The problem is exacerbated when raw material lead times are long So the question becomes how does one compute an accurate raw material (or WIP) safety stock, so this never happens?. Cost of goods sold = 600 x $2 = $10 $00 $10 = $800 3 Calculate the new finished goods inventory by adding the previous finished goods inventory value to the previous solution (COGM minus COGS) Example $800 $1600 = $2400 So, in this example, Jen’s Candles had a finished goods inventory worth $2400. Opening Stock Formula = Raw Material Cost Work in Progress Values Finished Goods Cost #2 – When current year closing stock is given along with sales and cost of goods sold and gross profit figures Opening Stock Formula = Sales – Gross Profit – Cost of Goods Sold Closing Stock Examples of Opening Stock.

Letter by CA~ Estimate of fees for carrying on Internal Audit;. The typical stock in the S&P 500 index yields about 18% at present However, in the materials sector, it is common to find stocks that offer dividends that pay at two times that rate or better. The raw materials inventory formula says that when you purchase raw materials, you debit your raw materials inventory asset account and credit accounts payable If you use up $100 of materials, you'd credit $100 to the raw materials account and debit $100 to works in progress or finished goods.

The problem is exacerbated when raw material lead times are long So the question becomes how does one compute an accurate raw material (or WIP) safety stock, so this never happens?. The formula to calculate the total cost of your raw materials inventory is Total Raw Materials = Beginning inventory Purchases added – Ending inventory Let’s say you own a scooter manufacturing company For this quarter, your starting inventory was worth $,000. You will just have to consider Op Stock of Raw Materials, Purchase and Cl Stock of raw materials Once Raw Materials are issued whether the same has been converted in finished goods or WIP it is not a matter Just apply this formulaRaw Mat Consumed=Op Stock of Raw MaterialsPurchase of Raw MaterialsCl Stock of Raw Materials.

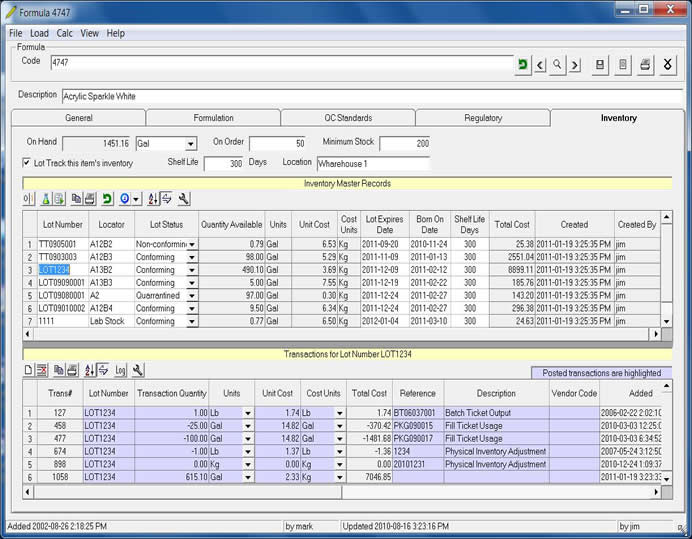

Closing Stock of Raw Material The value of closing stock of raw material is arrived at based on its type Raw Materials directly introduced into the process This is the stock left out of the stock of raw material acquired from sources outside the processes and introduced into the process during the current period. Two variables are used to calculate this KPI (1) the total dollar value (ie, cost) of raw materials in the inventory, and (2) the average dollar value of raw materials used per day To calculate the average raw materials used per day, divide the total dollar amount of raw materials used in a year by 365 days Raw materials should be defined as the parts directly used to manufacture a product (eg, lumber, paper, etc) KPI Formula (Total Value of Raw Materials Inventory / Average Value. The raw material stock table Consists of columns titled (raw material name, unit of measure, stock on hand and additional columns for other details My goal is to link these 3 tables so that the "stock on hand" column for raw materials will automatically update based on the information I enter in Table 1 when we produce product.

Safety stock level for leather packs would be (14 x 21) — (10 x 14) = 154 units and for backpacks (30 x 10) — (10 x 5) = 250 units As the manufacturing process consumes on average 10 packs. Average stock of materials = ½ ( Opening Raw material Computation of Purchase price of Raw Materials Overhead Costing Formula Like & Share Search for Search Recent Posts TCS Rate Chart for FY 19 and 21;. 7 Raw Materials Stocks with Material Dividends With a robust dividend, longterm investors have a lot to like about this key materials stock Just remember, however, that size isn't always a.

Using the three figures you have calculated above, you can now complete the safety stock formula To determine safety stock, simply multiply these three numbers 0128 x 8 days × 85 units = 8704 units Your inventory is now at 8704 units, or 870 as you would round decimals to the nearest number. Topic Raw Material Stock Register Looking for some Raw material stock control template in MS Excel format?. Safety stocks prevent stock outs when there is a high variation in demand and supply But what if the prices of the raw material whose product you sell sharply increases?.

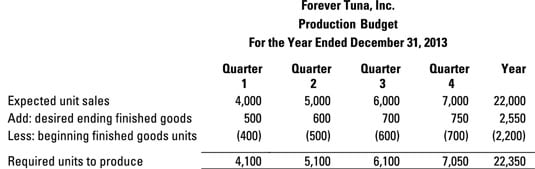

Stock maintain template holds great importance in different businesses due to benefits enjoyed if proper stock management is carried outCosts incurred by companies if operations are stopped due to lack of raw material in the store effects production budget, sales budget and schedules prepared for the specific project or as a whole. If the minimum stock level and average stock level of raw material A are 4,000 and 9000 units respectively, find out its reorder quantity Solution Average stock level = Minimum stock level ½ of Reorder Quantity 9000 = 4000 of Reorder Quantity. You can also create stock items for raw materials with excise applicable 1 Go to Gateway of Tally > Stock Items > Create 2 In Name field enter the stock item Name For example, Bottom Plate12Ltr 3 Group the Stock item Under the Stock Group RM Cooker (if Stock group is not created use Alt C from Under field to create the stock group) 4.

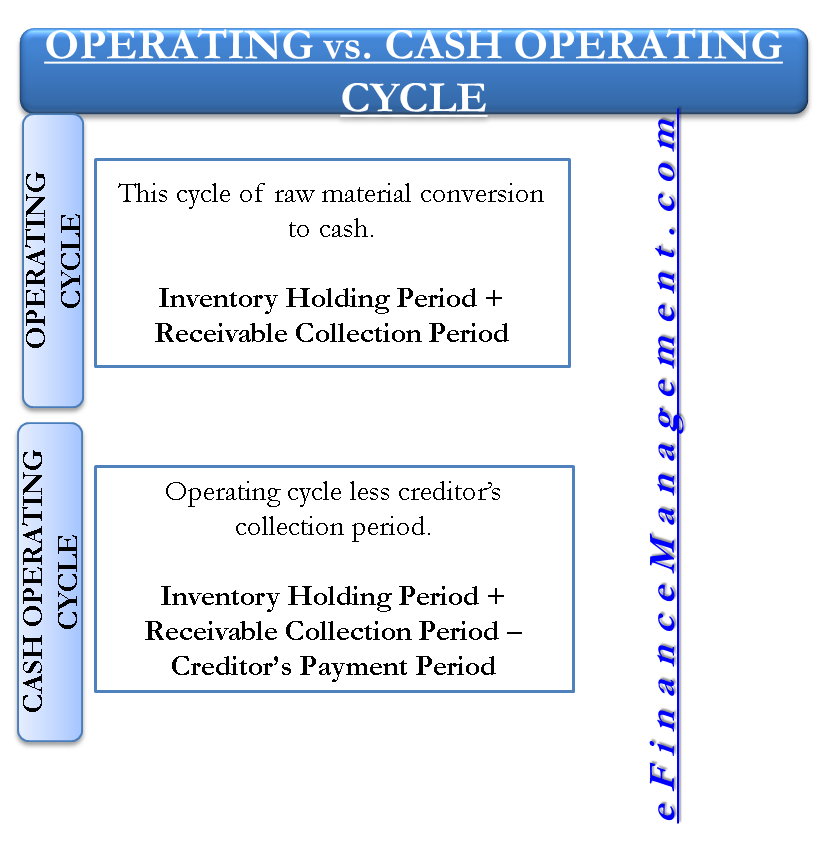

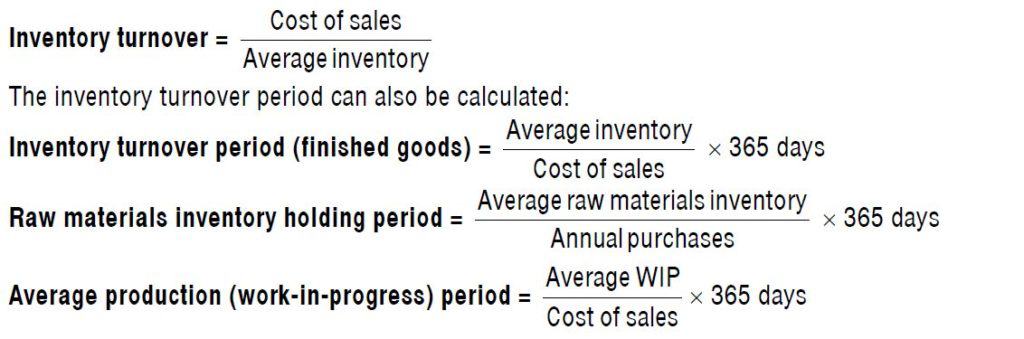

Now calculate average stock of raw material = (4060)/2 = 50 Now calculate raw material holding period = 50×12/ 80 = 750 months It implies that the on average basis the organization holds the raw material which will be consumed in 750 months or in other words it takes 750 months to convert the raw material into work in process. There are two different categories of raw materials — direct and indirect The formula to calculate the total cost of your raw materials inventory is Total Raw Materials = Beginning inventory Purchases added – Ending inventory Let’s say you own a scooter manufacturing company For this quarter, your starting inventory was worth $,000. The formula is given as In other words, the DOH is found by dividing the average stock by the cost of goods sold and then multiplying the figure by the number of days in that accounting period Note that the formula above divides the denominator by the number of days to generate the same result.

The total cost of the manufacturing overheads is $600 To calculate the raw materials inventory, add the cost of the direct materials in production with the manufacturing overhead In this case your raw materials inventory is valued at $6,000 Cost of the direct materials in production Manufacturing overhead. Here’s the ending raw materials inventory formula Ending Raw Materials Inventory = (Raw Materials Inventory Purchased Beginning Raw Materials Inventory) COGS Let’s use a clothing manufacturer as an example Consider BlueCart Tee Shirt Co They make and sell cotton tee shirts They have a beginning raw materials inventory of $10,000. A bill of materials (BOM) defines the components that are required in order to produce a product The components can be raw materials, semifinished products, or ingredients In some cases, services can be referenced in a BOM However, BOMs typically describe the material resources that are required.

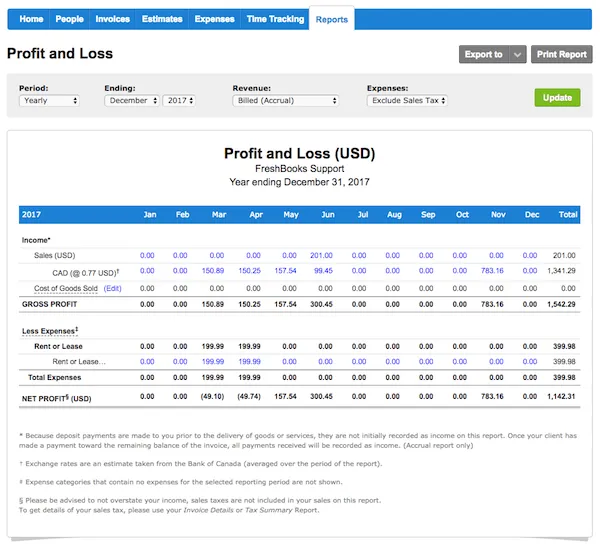

Factory cost of production during the year = Raw materials consumed Direct wages Other direct expenses Manufacturing overhead Opening WIP – Closing WIP 3 Finished Goods Storage Period. Definition Raw materials are the inputs or resources that a company uses to manufacture its finished productsIn other words, this is the unprocessed material like metal stock, rubber blanks, or unrefined natural resources that companies use in there manufacturing processes to produce finished goods to sell to consumers What Does Raw Materials Mean?. Time to uncover the value of your remaining inventory, and this is simple, simple multiple your remaining inventory by the cost for one unit of raw material $90 laces x $150 = $135 And there you have it, the remaining raw material inventory level’s value comes in at $135.

Raw materials inventory is the total cost of all component parts currently in stock that have not yet been used in workinprocess or finished goods production There are two subcategories of raw materials, which are Direct materials These are materials incorporated into the final product For example, this is the wood used to manufacture a. For calculating yield of finished goods (actuals), the formula is = Actual voulme (Qty) of Production divided by actual volume (Qty) of Raw materials consumed Now, coming to Percentage yield Percentage yield = Actual Yield divided by Standard yield Posted 7 years ago by HS VEDANTA DESHIKA. Manufacturing – inventory and sales manager – excel template – v2 free download raw material stock format in excel__/LINKS\_ Facebook https//www.

Do not include indirect raw materials (eg, wood finish placed on a manufactured chair, etc) in this calculation KPI Formula Total Cost of Goods Sold / ((Inventory Value of Raw Materials at Start of Measurement Period Inventory Value of Raw Materials at End of Measurement Period) / 2). You can also create stock items for raw materials with excise applicable 1 Go to Gateway of Tally > Stock Items > Create 2 In Name field enter the stock item Name For example, Bottom Plate12Ltr 3 Group the Stock item Under the Stock Group RM Cooker (if Stock group is not created use Alt C from Under field to create the stock group) 4. The answer is properly calculated Component Safety Stock (CSS) Syllabus 1 Rationale behind Component Safety Stock (CSS) 2.

Raw materials inventory is the total cost of all component parts currently in stock that have not yet been used in workinprocess or finished goods production There are two subcategories of raw materials, which are Direct materials These are materials incorporated into the final product For example, this is the wood used to manufacture a. Calculators, engineering calculators Enter value, select units and click on calculate Result will be displayed. Raw material stock statement is considered necessary these days, as it shows the real worth of the assets Reporting template excel is also asked by the board of directors as well as loan providing bodies to consider whether the company is able to return the loan with interest amount regularly or not These sheets are also required by project managers to determine whether working on the.

Periodic Inventory System Methods And Calculations Netsuite

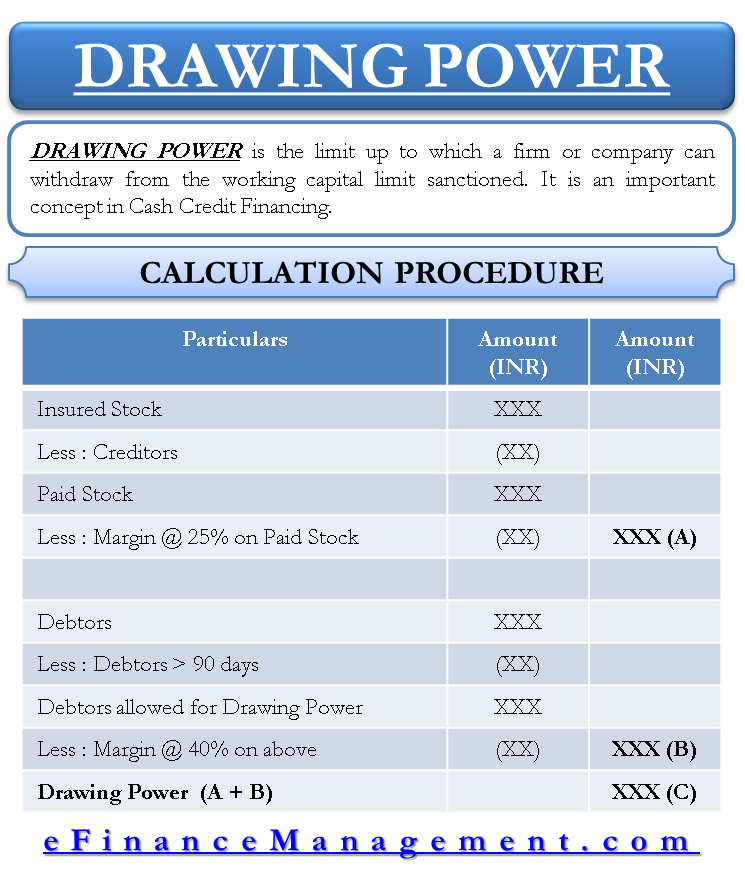

Drawing Power

Manufacturing And Non Manufacturing Costs Online Accounting Tutorial Questions Simplestudies Com

Raw Material Stock Formula のギャラリー

Working Capital Cycle Days Ratios Financial Edge Training

Inventory Aging Report And How To Calculate The Ultimate Guide

Working Capital

Calculate Ending Inventory Formula Explanation Video Lesson Transcript Study Com

Managerial Accounting Spring 19 Lab 2 Chapter 3 Excel Computer Problem The Following Data Refer To Miller Widget Company For The Year X1 Course Hero

How To Maintain A Par Inventory Sheet For Your Restaurant Limetray S Restaurant Management Marketing Blog

What Is Safety Stock

Ending Work In Process Double Entry Bookkeeping

Materials Accounting Powerpoint Slides

What Is A Work In Progress Wip Robinhood

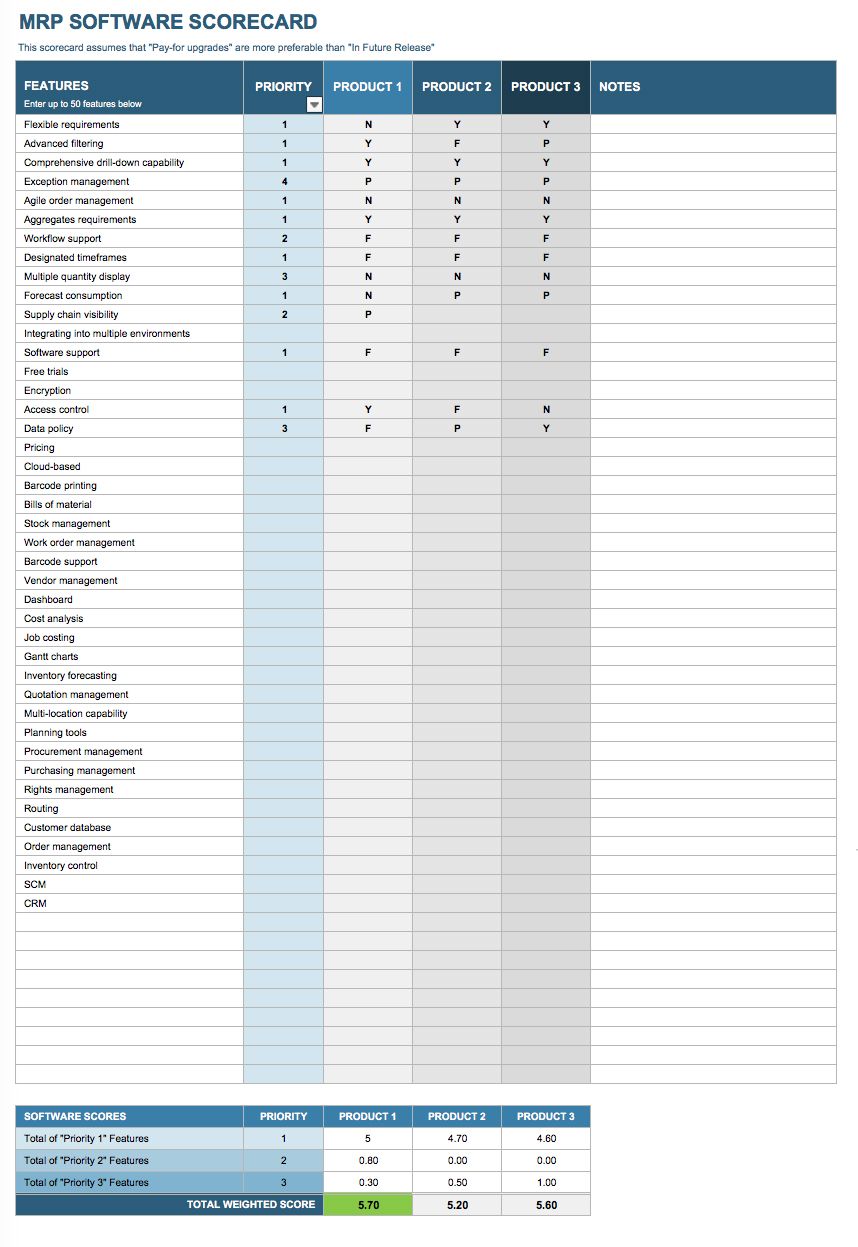

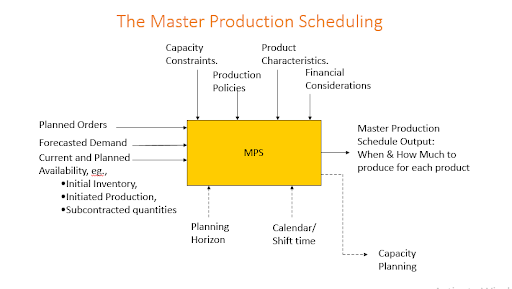

Everything You Need To Know About Material Requirements Planning Mrp Smartsheet

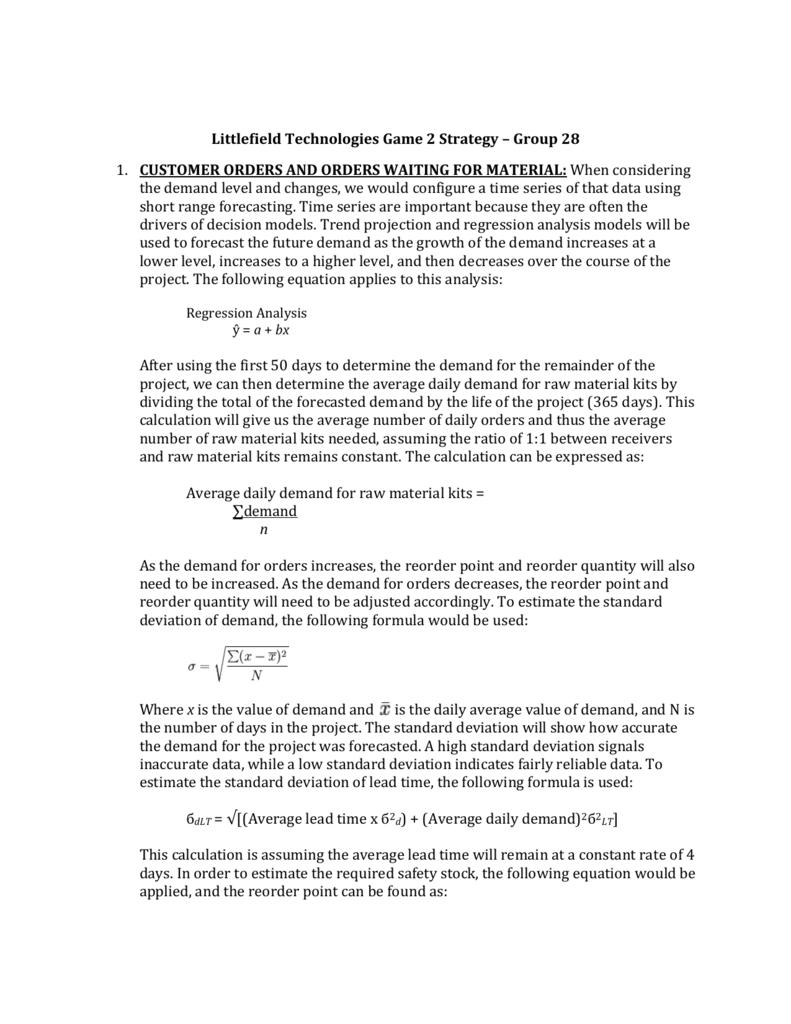

Littlefield Technologies Game 2 Strategy Group 28 1 Customer

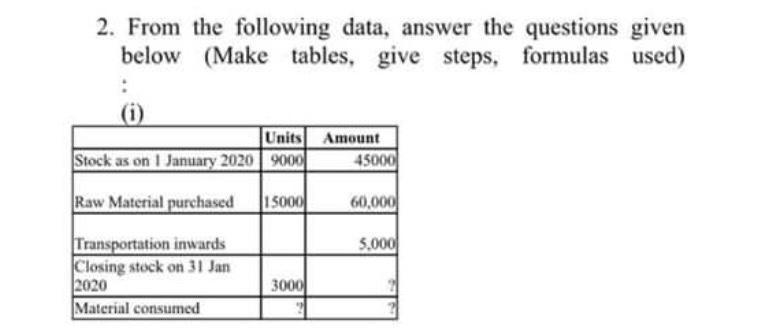

Solved 2 From The Following Data Answer The Questions G Chegg Com

Download Cost Sheet With Cogs Excel Template Exceldatapro

Inventory Control

6 Best Safety Stock Formulas On Excel Abcsupplychain

Manufacturing And Non Manufacturing Costs Online Accounting Tutorial Questions Simplestudies Com

Inventory Model Simulation With Spreadsheets Datacamp

Raw Material Inventory Management The Definitive Guide

What Is Inventory Turnover Inventory Turnover Formula In 3 Steps

_files/image004.jpg)

Sage 50 Accounting Integration Getting Started

What Is Inventory Management 10 Guides To Mastering Commerce

What Is Closing Stock Examples Calculations Tally Solutions

Demonstration Problem Ppt Download

What Is Cost Of Goods Sold Cogs And How To Calculate It

Operating Cash Operating Cycle Formula Calculation Example Analysis

Ending Inventory Formula Step By Step Calculation Examples

Raw Material Inventory Management The Definitive Guide

Managerial Accounting 15th Ed Chapter 3

Production Budget Definition Explanation And Examples Play Accounting

Inventory Turnover How To Calculate Inventory Turns

Inventory Management Software For Manufacturing Mrpeasy

Understanding P L Statement Part 2 Varsity By Zerodha

Financial And Managerial Accounting Wild Shaw And Chiappetta Fifth Edition Wild Shaw And Chiappetta Fifth Edition Mcgraw Hill Irwin Copyright C Ppt Download

Finding The Closing Stock Valuation Using A Single Formula Stack Overflow

Days Inventory On Hand Lean Math

Inventory Control

Raw Material Supply An Overview Sciencedirect Topics

Opening Stock Meaning Examples Top 3 Types Of Opening Stock

10 Inventory Metrics You Need To Know Inventory Management Metrics

3 Types Of Inventory Raw Material Wip Finished Goods

Cost Of Goods Manufactured Cogm How To Calculate Cogm

Raw Material Stock Register Format In Excel Excel124

Valuing Inventory Boundless Accounting

Process Cost System

Manufacturing Account Format Double Entry Bookkeeping

Working Capital Requirements In A Manufacturing Business Plan Projections

Manufacturing A Quality Premix The Poultry Site

Periodic Inventory System Methods And Calculations Netsuite

First In First Out Fifo Method In Periodic Inventory System Accounting For Management

Inventory Manager

Set A Direct Materials Budget As Part Of Your Master Budget Dummies

Calculating Cost Of Goods Sold In Manufacturing Mrpeasy

Working Capital

Operating Cycle Definition Formula Calculation Example

6 Best Safety Stock Formulas On Excel Abcsupplychain

What Is Dock To Dock Time And How Is It Calculated

3 Types Of Inventory Raw Materials Wip And Finished Goods Youtube

Managerial Accounting 15th Ed Chapter 3

Days Sales In Inventory Dsi Overview How To Calculate Importance

Materials Purchases Budget Accounting Education

How To Calculate Safety Stock Safety Stock Formula Orderhive

Excel Inventory Sheet Template Word Excel Templates

Materials Accounting Powerpoint Slides

Set A Direct Materials Budget As Part Of Your Master Budget Dummies

Raw Materials Inventory Definition Formula And Turnover

:max_bytes(150000):strip_icc()/TeslaQ2-19IncomeStatementInvestopedia-1466e66b056d48e6b1340bd5cae64602.jpg)

Does Gross Profit Include Labor And Overhead

3 Types Of Inventory Raw Material Wip Finished Goods

Income Statements For Manufacturing Companies

How To Maintain Fabric Trim And Accessory Record In An Excel Sheet

Free Inventory And Stock Management Tool In Excel Zervant Blog

How To Use The Safety Stock Formula A Step By Step Guide

Ending Inventory Formula Step By Step Calculation Examples

Relevant Cost Of Material Rules Example

Inventory Turnover Ratio Formula Meaning Example And Interpretation

Solved Refer To Qs 18 12 And Compute Raw Materials Inventory T Chegg Com

Inventory Management 101 The Master Production Schedule Mps Explained Optipro Software

Ratio Analysis

Inventory Flow Analysis Springerlink

Raw Materials Inventory Definition Formula And Turnover

Inventory Purchases Budget Plan Projections

Production Budget Definition Explanation And Examples Play Accounting

Ending Inventory Formula Calculator Excel Template

Excel Inventory Template For Manufacturing Businesses Bill Of Materials

Understanding P L Statement Part 2 Varsity By Zerodha

3 4 Journal Entries For The Flow Of Production Costs Managerial Accounting

Ending Inventory Formula Calculator Excel Template

Sample Excel Sheet Calculating Inventory Holding Costs Driveyoursucce

Stock Ageing Analysis Reports Using Excel How To Pakaccountants Com

What Is Safety Stock

Days Inventory Outstanding Top 2 Examples With Excel Template

Raw Material Supply An Overview Sciencedirect Topics

Ending Inventory Formula Calculator Excel Template

Sample Excel Sheet Calculating Inventory Holding Costs Driveyoursucce