Lean Production Beispiel

Likewise, if your shareholders want to see production increase over the next year, you’ll have to find ways to meet their expectations while keeping costs low Simply put, you can expect to manage projects that help keep your organization operating effectively, efficiently, and within budget.

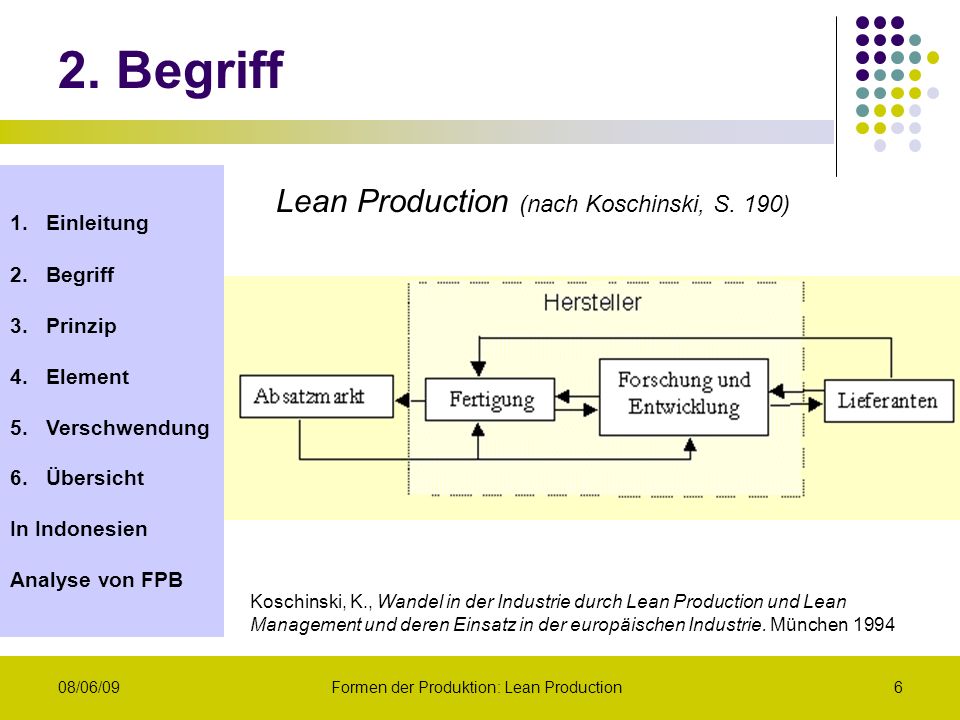

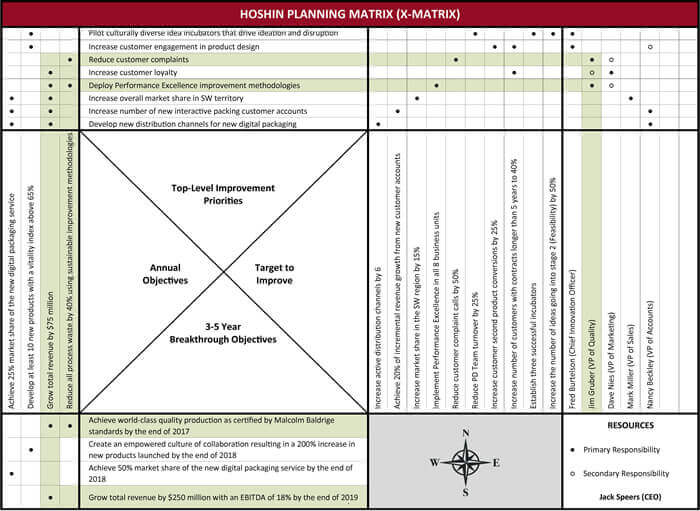

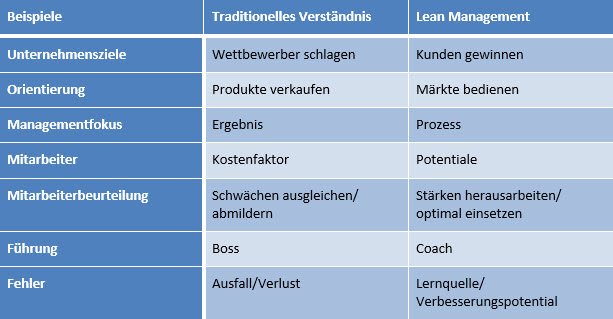

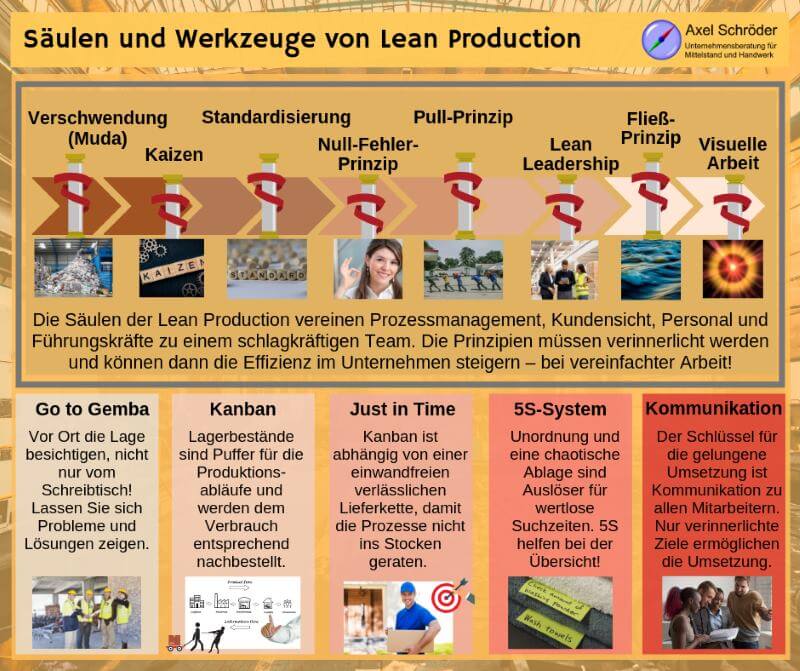

Lean production beispiel. Nonprofit Improving Grant Submission Cycle Time by an Entire Week With Amanda Booth. Seite 9 Bausteine Lean Kultur ganzheitliches KVP Das Gestalten und Überwachen der Systeme ist Teil der täglichen Arbeit der Führungskräfte Standard Work auch für Führungskräfte Führungskräfte leben die LeanPrinzipien vor Leite aus der Unternehmensstrategie Ziele ab und breche sie kaskadenförmig auf Ziele für alle Bereiche herunter. Lean Production (Introduction) Lean production is an approach to management that focuses on cutting out waste, whilst ensuring quality This approach can be applied to all aspects of a business – from design, through production to distribution Lean production aims to cut costs by making the business more efficient and responsive to market needs This approach sets out to cut out or minimise activities that do not add value to the production process, such as holding of stock, repairing.

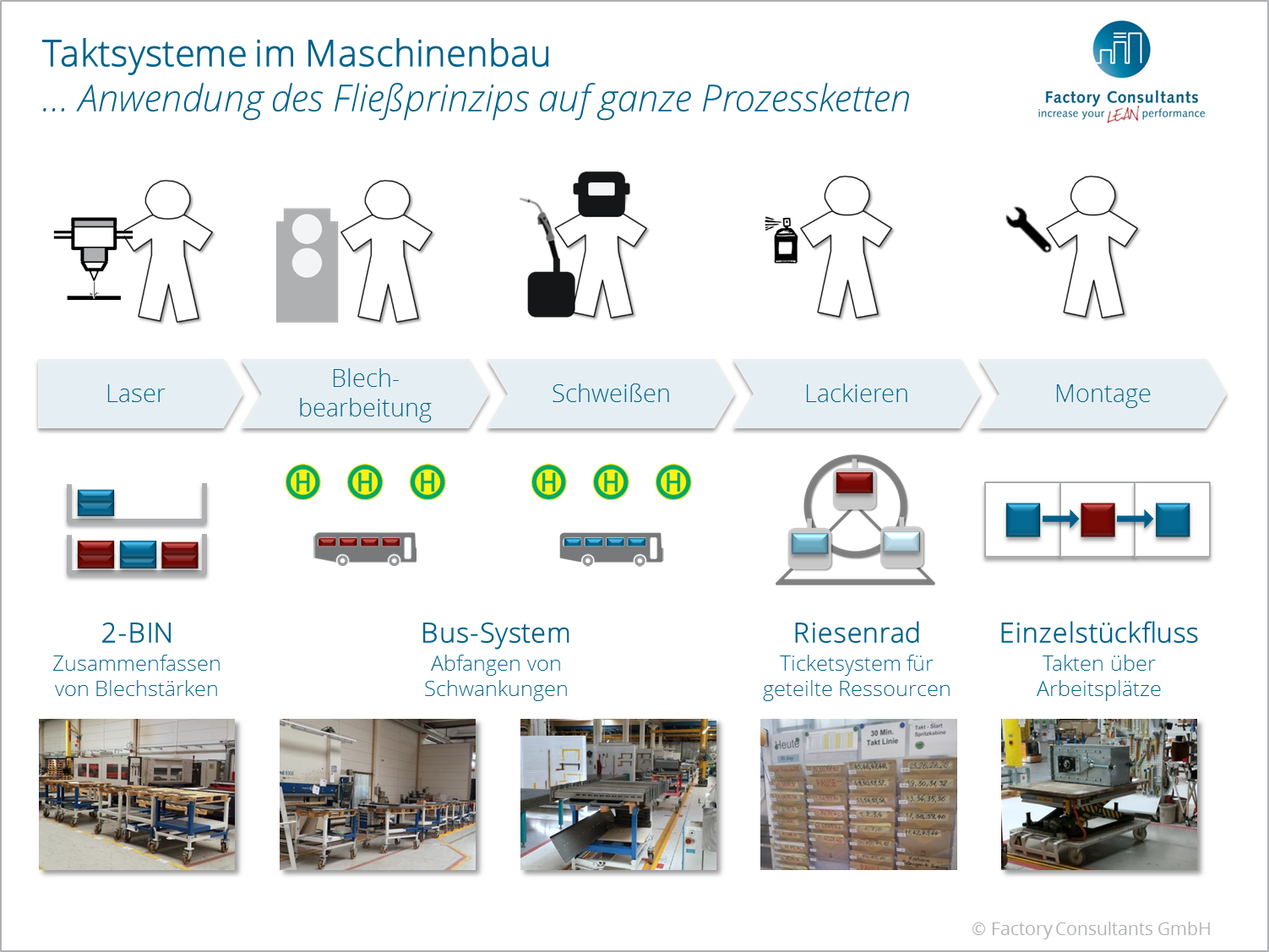

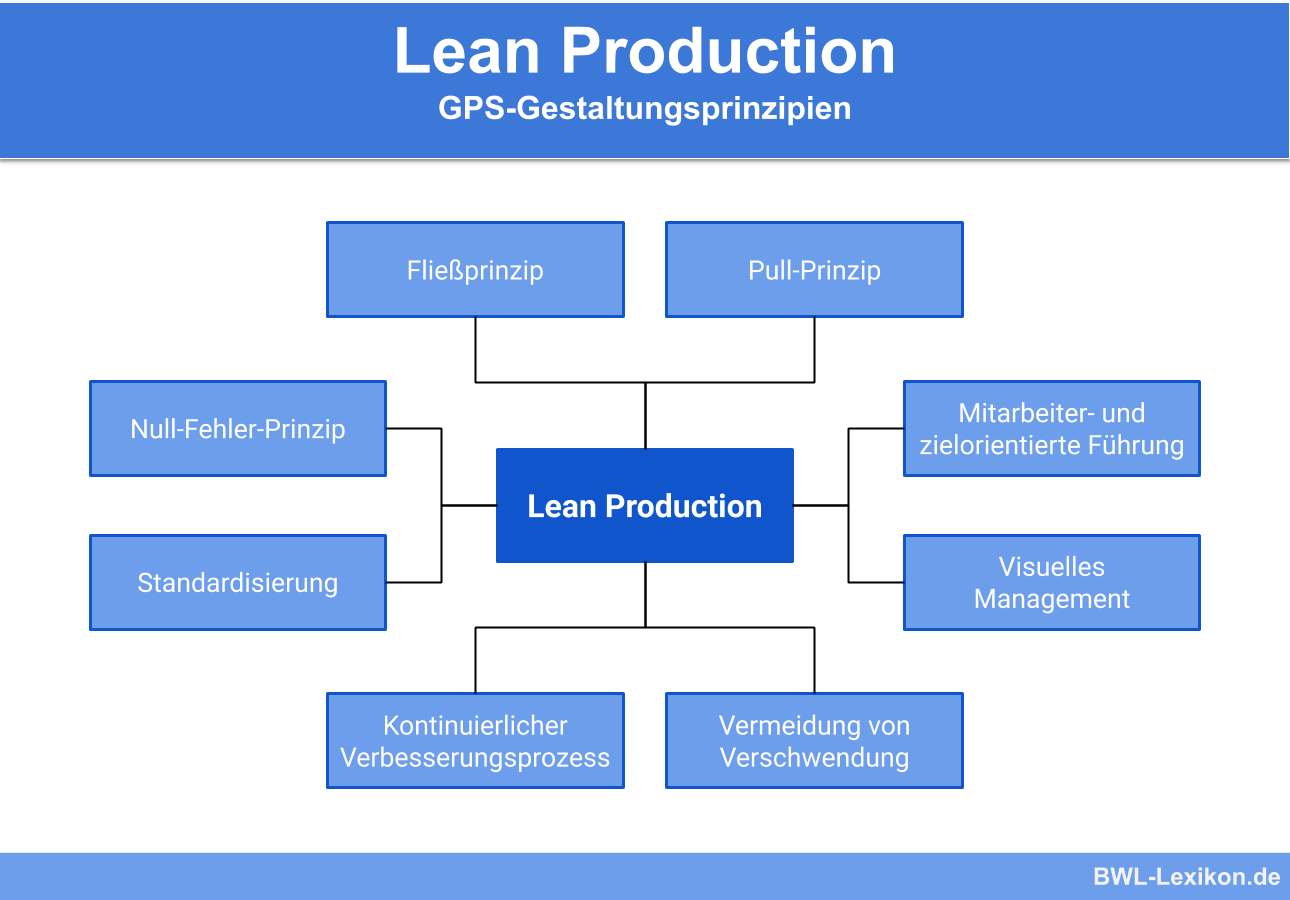

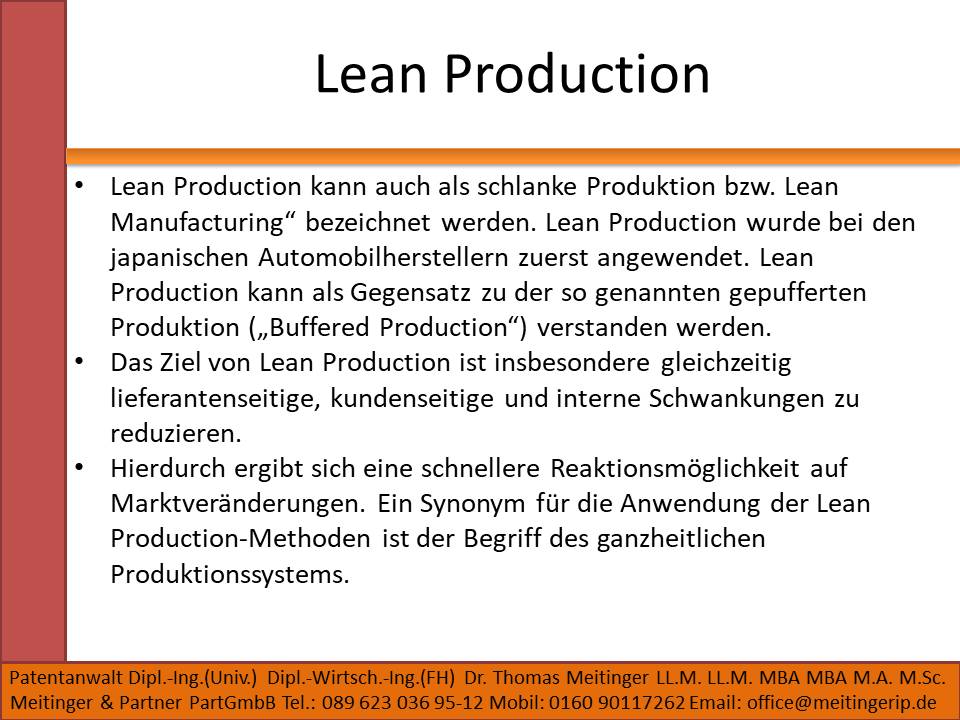

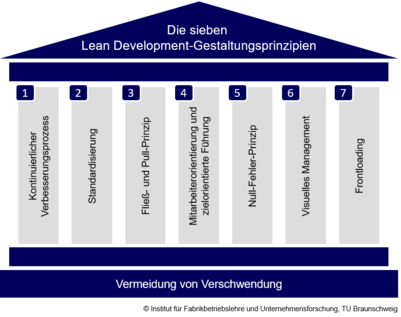

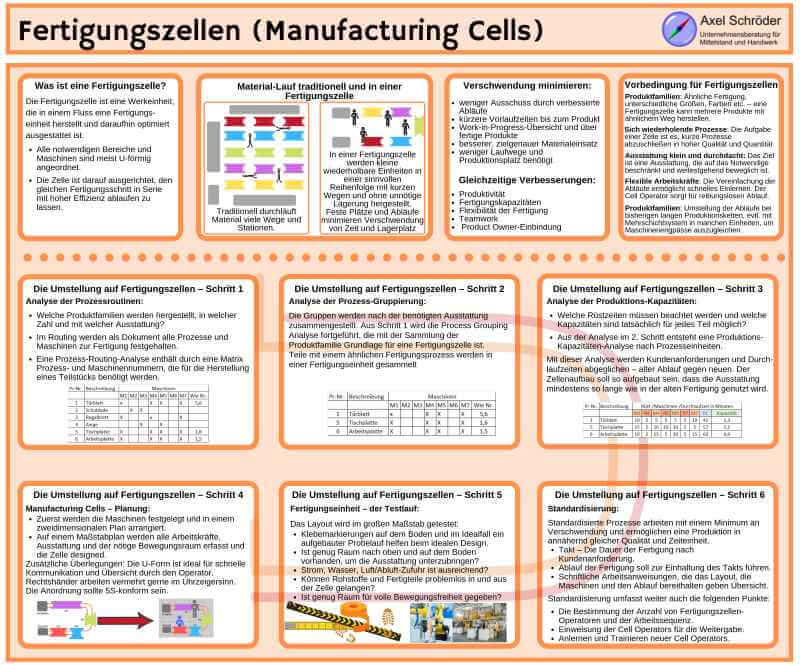

Lean Six Sigma For NonIndustrial Organizations Compared to the past, Lean Six Sigma is now making way into hospitals, banks and municipalities very often The industrial industry primarily utilized Lean Six Sigma methods to produce and deliver products It’s going beyond product delivery and straight into customer satisfaction. Even if a lean production is characterized by very flat hierarchies and many principles seem agile, lean production is not completely agile in itself In order to be able to better serve customer requests, the production philosophy of “Agile Manufactoring” was born. Beispiel Zu der LeanProduction gehören beispielsweise die verschiedenen Verwendungsarten der Standartisierung von sich wiederholenden Prozessen oder Arbeitsabläufen oder das Fließprinzip, dass einen schnellen, durchgängigen und ohne Probleme fließenden Arbeitsablauf garantiert Teile diesen Artikel twittern ;.

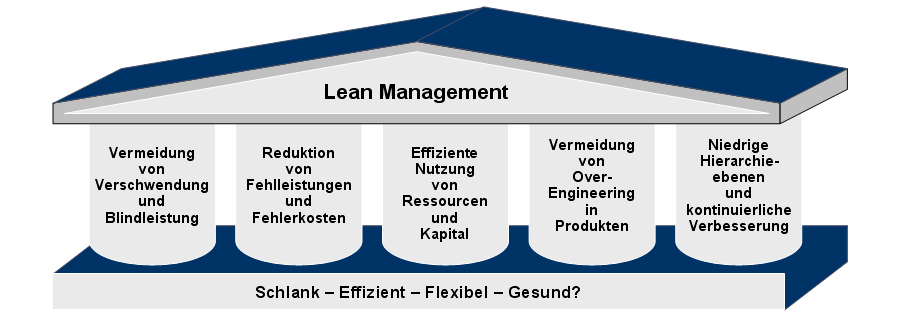

Beispiel Zu der LeanProduction gehören beispielsweise die verschiedenen Verwendungsarten der Standartisierung von sich wiederholenden Prozessen oder Arbeitsabläufen oder das Fließprinzip, dass einen schnellen, durchgängigen und ohne Probleme fließenden Arbeitsablauf garantiert Teile diesen Artikel twittern ;. Lean Management einfach erklärt Definition, Produktion, Personal, Kunden, Pro & Contra "Schlankes Management" als Führungskonzept für Qualität und optimie. MoreSteam is the leading global provider of online training, certification, and technology for Lean Six Sigma Partners Industry associations, leading universities, and partners trust MoreSteam Our Team Meet the people behind the software who are dedicated to helping you solve business problems.

But if you want to create real value and jobs that value people, you must think hard about how your people are working every day That’s because the essence of lean thinking is about the work Lean thinking and practice mean working on the work the valuecreating work that occurs on the frontlines of your enterprise. The job instruction sheet is used to train new operations It lists the steps of the job, detailing any special knack that may be required to perform the job safely with utmost quality and efficiency It can also be useful for experienced operators to reconfirm the right operationsThe job instruction sheet is one of three basic forms for creating standardized work, along with the standardized. And “lean startup,” a set of principles and practices developed in Silicon Valley over the past decade that help entrepreneurs and intrapreneurs launch new products and services 1 Think of lean production as a way to maximize the efficiency.

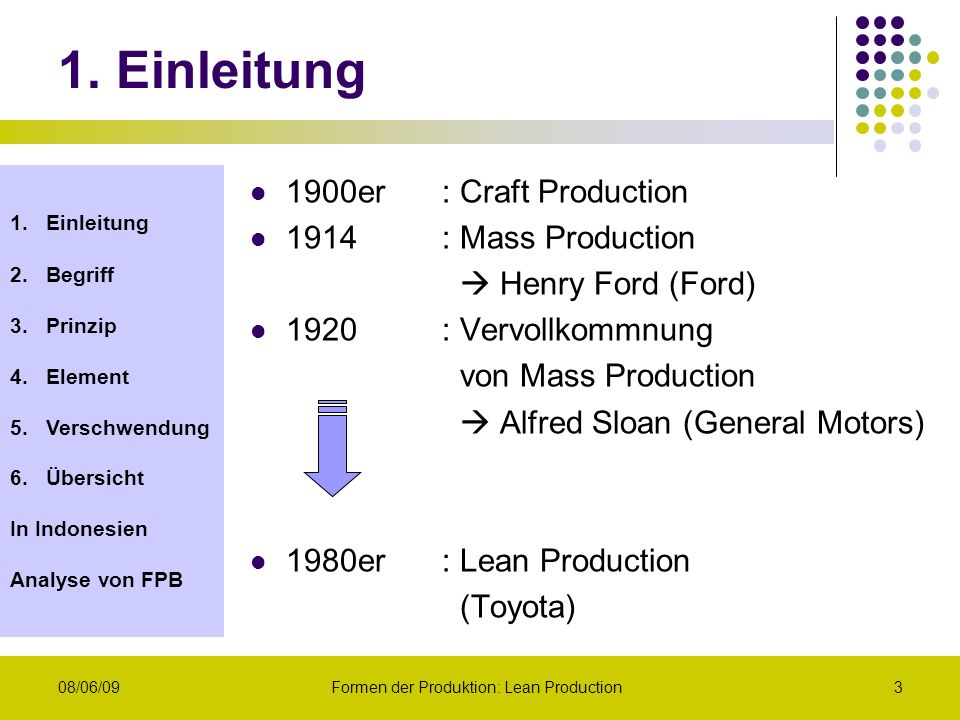

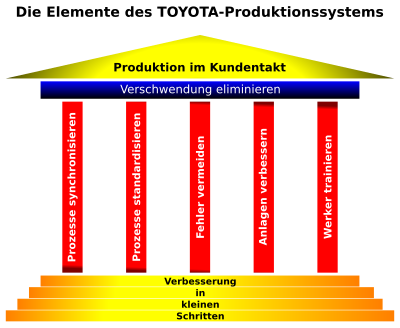

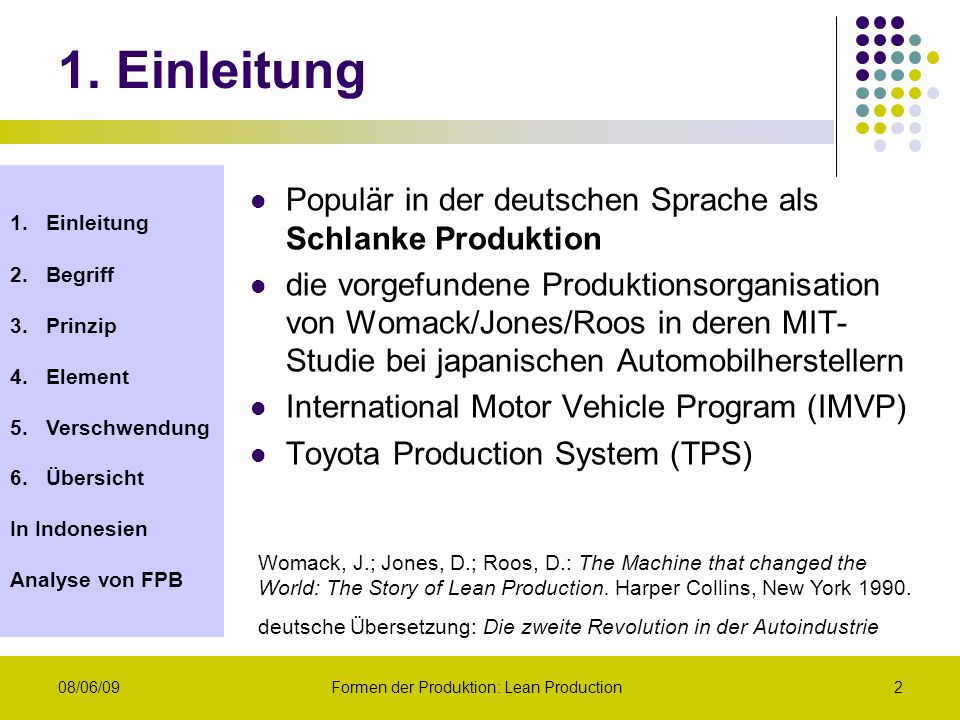

Lean Production am Beispiel Toyota Grundlage für die heutige Lean Production war das ToyotaProduktionssystem, auch TPS genannt Der damalige Vorsitzende der Toyota Motor Cooperation sah sich aufgrund von Sparmaßnahmen, einer Isolationspolitk und einer bestehenden Knappheit an Rohstoffen gezwungen, zu einer JustinTime Produktion überzugehen. Many organizations embrace lean methodology (also known simply as "lean"), a systemic approach to streamlining production, to make operations more efficient Done correctly, lean methodology not only solves problems, but also provides value to customers better and simpler than before Unfortunately, organizations sometimes go overboard with the lean principle of eliminating waste, cutting what’s actually needed to do the job right — paradoxically reducing effectiveness. Lean has two distinct strains “lean production” (also known as “lean manufacturing”), a structured method first developed by Toyota more than 25 years ago that applies to complex processes like manufacturing, logistics, and health services;.

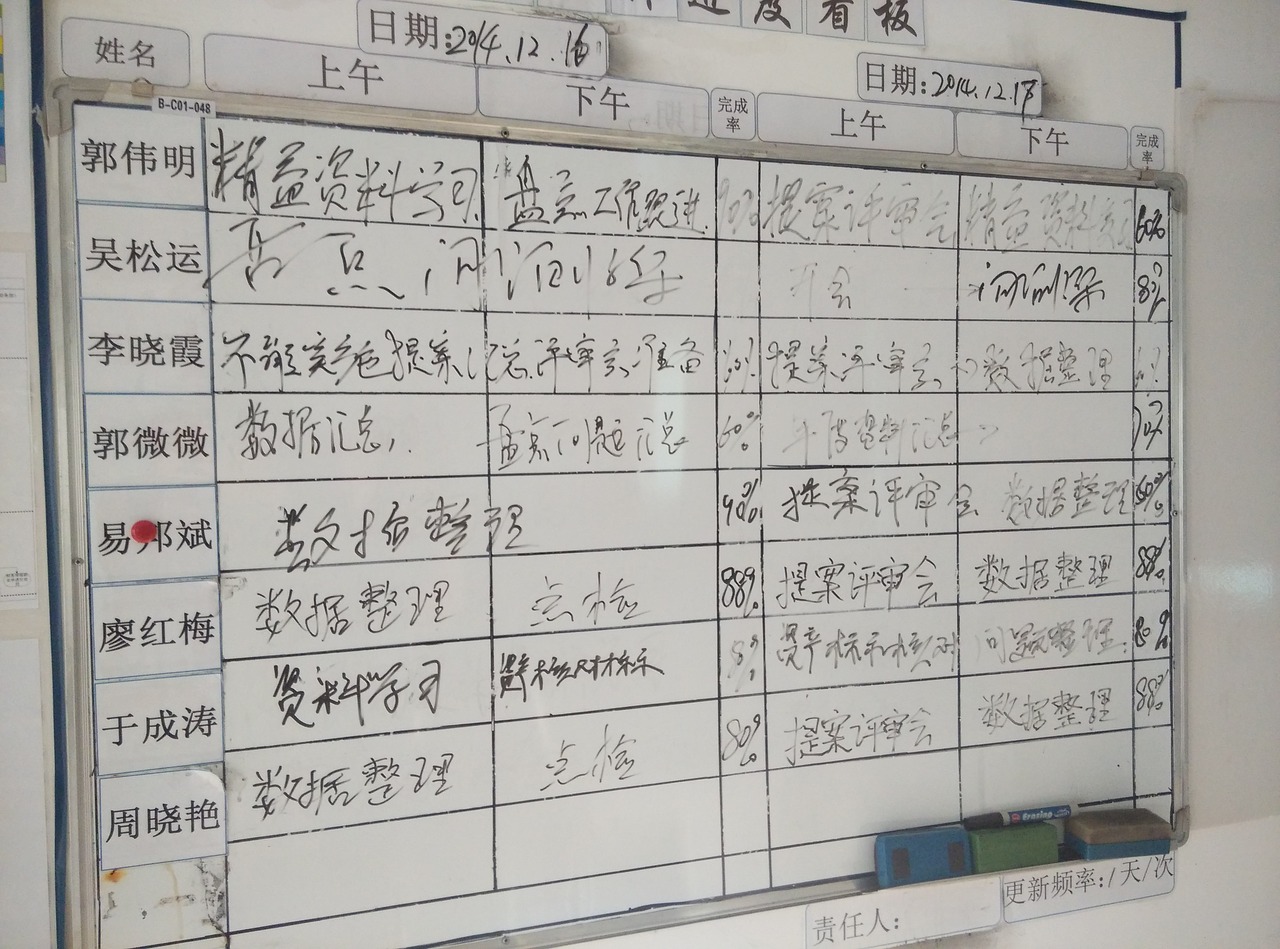

A Takt board is a production tracking board that captures the variances between planned production and actual production This variance can be tracked by shift, by hour, by day or by work order The board is often positioned on the shop floor in order to keep employees uptodate on the company's progress. As the steelmaker’s example suggests, the key to applying advanced analytics in leanproduction environments is to view data through the lens of continuous improvement and not as an isolated series of oneoffs The ability to solve previously unsolvable problems and make better operational decisions in real time is a powerful combination. Mit dem Begriff „lean production“ (dt „schlanke Produktion„) bezeichnet man den sparsamen und effizienten Einsatz von Ressourcen wie Betriebsmitteln, Personal, Werkstoffen und Zeit bei allen UnternehmensaktivitätenDer Begriff wurde 1992 durch die Schriften von James P Womack, Daniel T Jones und Daniel Roos in die wirtschaftswissenschaftliche Diskussion eingeführt.

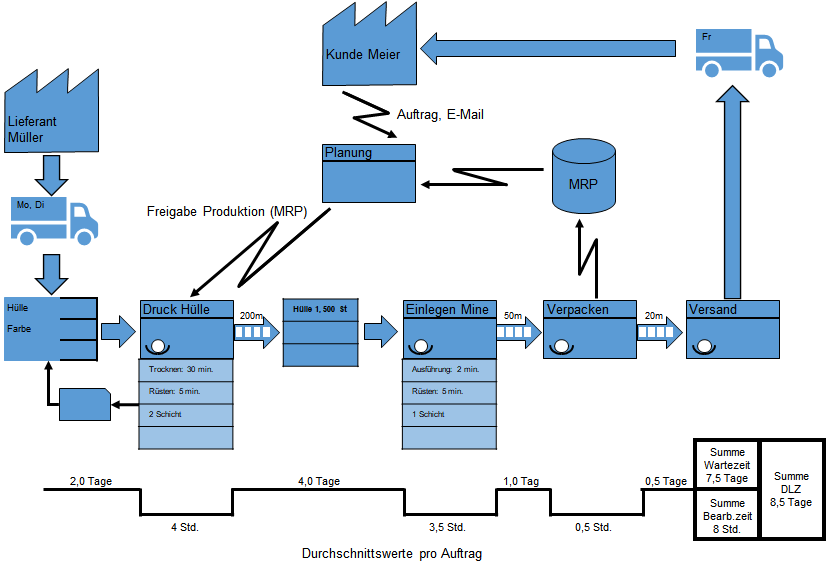

Lean Manufacturing 3 min read Lead time is the amount of time it takes from the moment a customer places an order to the moment the product is out for a delivery This includes any time taken to manufacture materials for the finished product or the time it takes to receive the materials All activities, wasteful or not, add up to the lead time Consequently, it's beneficial to reduce waste by implementing Lean strategies. In lean manufacturing systems, poka yoke also includes a philosophy of constantly working to prevent mistakes from occurring in the first place The internal processes in lean manufacturing systems are supposed to produce quality products the first time Errorproofing in this case is a quality assurance technique that ensures quality is in. The impact that this approach can have on a company’s production environment and lean manufacturing initiatives is clear, but the benefits also extend beyond the factory floor Giving frontline employees a voice in the improvement process can help build a manufacturing culture that excels at problemsolving, encourages innovation, and.

Lean is a production management strategy for achieving significant, continuous improvement in the performance of the total business process of a contractor through elimination of all wastes of time and other resources that do not add value to the product or service delivered to the customer (Womack et al 1996). Production Management 105 Master Production Scheduling a MTS `produces in batches `minimizes customer delivery times at the expense of holding finishedgoods inventory `MPS is performed at the enditem level `production starts before demand is known precisely `small number of enditems, large number of rawmaterial items a MTO `no finished. Lean Zone® Production Methodologies $ ;.

Prinzipien des Lean Managements Lean Production & Lean Management Elemente der Lean Production Literaturverzeichnis 1 Definition 2 Vor und Nachteile 3 Beispiele in Unternehmen 4 Kritik Definition Lean Production. This type of production system is usually the ultimate goal of any lean system In fact, most of the writing in manufacturing and many of the lean methods concern the flow shop The other methods, job shop and project shop, often feel even neglected to me But then, it is just so much easier to perfect a flow shop than the other two Repeatability!. Lean Budgets is a LeanAgile approach to financial governance, which increases throughput and productivity by reducing the overhead and costs associated with project cost accounting When implementing Agile at scale, many organizations quickly realize that the drive for business agility through LeanAgile development conflicts with traditional budgeting and project cost accounting methods.

Key Performance Indicators for Production Monitoring Posted in Canada, Education, General on 22/04/14 Lean manufacturing focuses on eliminating sources of waste and continuously looking for ways to improve the organization In order to assess and measure the processes, organizations often use Key Performance Indicators (KPIs). Heijunka (pronounced hiJUNEkuh) is a Japanese word that means “leveling” When implemented correctly, heijunka elegantly – and without haste – helps organizations meet demand while reducing while reducing wastes in production and interpersonal processes According to many Lean experts, heijunka is better achieved as a laterstage implementation in a Lean organization, long after. Taiichi Ohno, who is considered the main architect of the Toyota Production System, devoted his career to eliminating waste (Muda) from production processes He probably realized this is the right way to generate value for the customer Ohno was able to identify various activities in different work processes, which can be removed.

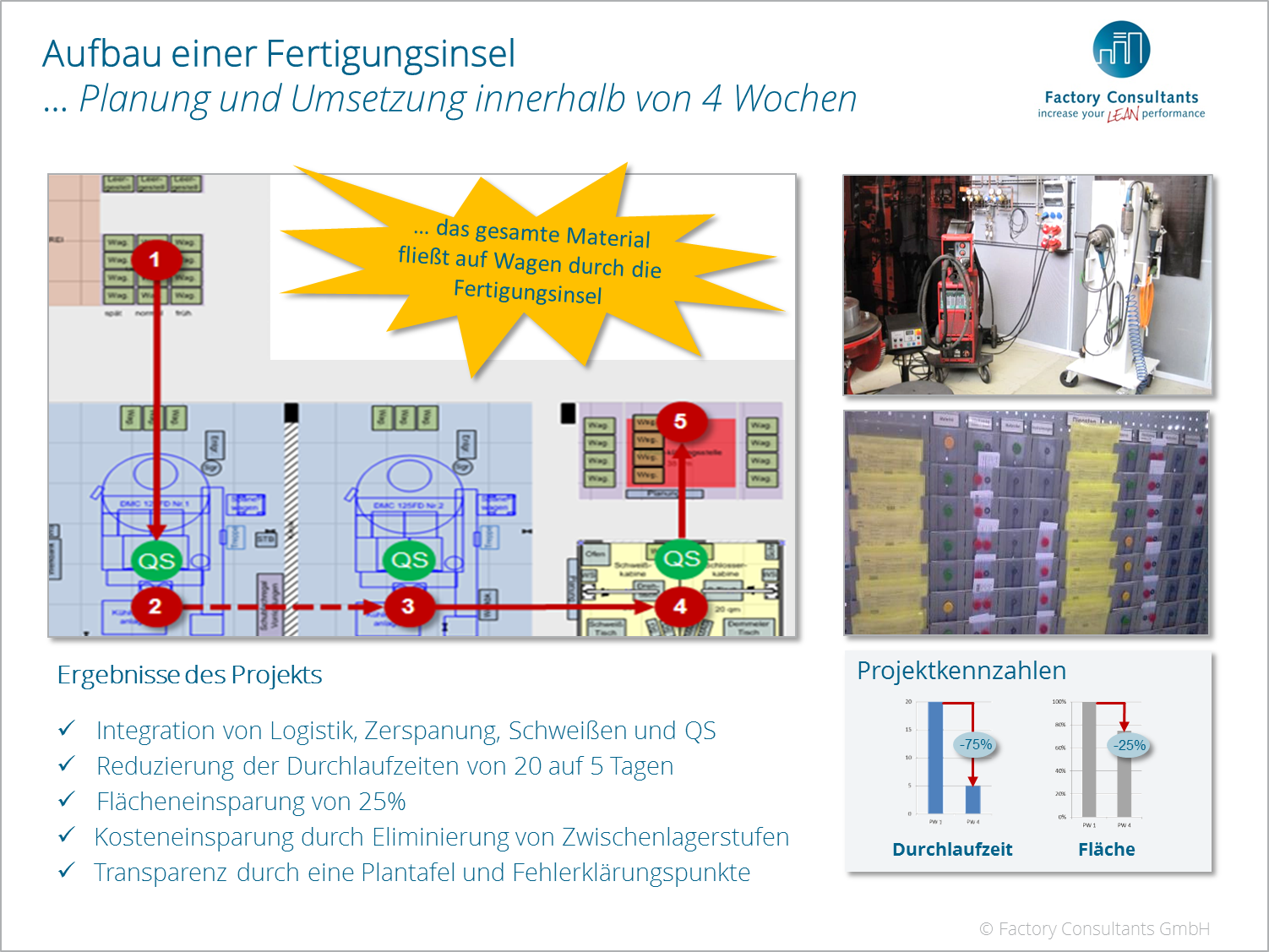

Lean Production Systems are the acknowledged benchmark for the efficient design of production processes in order to enable companies to compete on product variety, lead times, delivery reliability. Ein Beispiel Im Werk Wettenberg, wo überwiegend Bediensysteme und Sicherheitssteuerungen hergestellt werden, haben wir die Fertigung neu strukturiert und Produktionsinseln eingerichtet, die nach dem Prinzip der Lean Production aufgebaut sind. Lean is a suite of four complementary, interconnected principles, each geared towards increasing value to the customer by improving efficiency By applying these simple principles, any business in any sector can not only provide a better service or product to their end users, but also make fundamental, sustainable improvements in profitability.

Frank Bertagnolli ist Professor für Lean Production und Ressourceneffizienz an der Hochschule Pforzheim Er lehrt die Themen Lean und Change Management im Bachelorstudiengang BWL RessourceneffizienzManagement und dem Masterstudiengang Life Cycle & Sustainability. Likewise, if your shareholders want to see production increase over the next year, you’ll have to find ways to meet their expectations while keeping costs low Simply put, you can expect to manage projects that help keep your organization operating effectively, efficiently, and within budget. Manufacturing Lean Six Sigma Project Increases Production by 58% and Lowers Energy Costs by $263K for British Aerospace Supplier, Featuring James Yates;.

One of IMVP’s researchers, John Krafcik, is credited with coining the term “Lean production”1 The system uses less of everything involved in production manpower, investment, engineering, inventory, facilities, and so on, thus the term “Lean” fits well. Lean manufacturing refers to eliminating waste, reducing costs, and improving production with finite resources As a result, many manufacturers have deployed extensive process review and analysis programs to move towards a higher level of lean manufacturing Yet, mobility is poised to make the most dramatic impact on the concept and use of lean. Lean Production Enthält Beispiele · Definition · Grafiken · Übungsfragen Die schlanke Produktion (engl Lean Production), ist ein Konzept, welches die Produktion optimiert Hierzu werden die Produktionssysteme verschlankt, was über acht Gestaltungsprinzipien erfolgt, die nach VDI 2870 festgelegt sind.

Jürgen Reichardt, Christian Gottswinter, and Candy Patrick Schulze (10) Lean Production in der Fabrikplanung am Beispiel eines Automobilzulieferers ZWF Zeitschrift für wirtschaftlichen Fabrikbetrieb Vol 105, No 4, pp. HyPlan Lean‐Kennzahlen‐Tool Kurzbeschreibung Axel Korge Tobias Krause Xiang Nie Stand 1311 Das HyPlan LeanKennzahlenTool ermöglicht es den Nutzern wichtige Kennzahlen zu ermitteln Die Werkzeuge von HyPlan unterstützen kleine und mittlere Unternehmen (KMU) bei der Einführung von LeanManagement. Lean close definition When you close something such as a door or lid or when it closes , it moves so that a Meaning, pronunciation, translations and examples.

Lean Production ist ein Term, den westliche Wissenschaftler und Praktiker einer Produktionsmethode gegeben haben, die sie bei Toyota in Japan studiert haben Es handelt sich also um die westliche Interpretation eines japanischen Produktionssystems Dieses System hat sich seit etwa 1960 über mehrere Jahrzehnte entwickelt, es besteht aus einer Reihe von Werkzeugen, aber insbesondere aus grundsätzlichen Herangehensweisen und Philosophien. Six Sigma Improves the Environment A Look at a Baxter Manufacturing Six Sigma best practices are instrumental in changing the way businesses operate Motorola recognized this in the 1980s when the company employed Six Sigma principles in manufacturing processes. Six Sigma Root Cause Analysis Online Training (Complete with Certification) $ 2999 Lean Six Sigma White Belt Online Training (Complete with Certification) $ 2999 The Greatest LEAN Pull Game Ever!.

Einstein is quoted as having said that if he had one hour to save the world he would spend fiftyfive minutes defining the problem and only five minutes finding the solution This quote illustrates an important point before jumping right into solving a problem, we should step back and invest time and effort to improve our understanding of it. Strategische Philosophien oder Praktiken wie zum Beispiel Kaizen, Lean Manufacturing, Six Sigma, Total Quality Management und Continuous Improvement werden in vielen Organisationen verwendet, um Prozesse zu optimieren, die Produktivität zu steigern und in einer zunehmend globalisierten Wirtschaft einen Wettbewerbsvorsprung zu wahren Trotz. 301 Moved Permanently nginx.

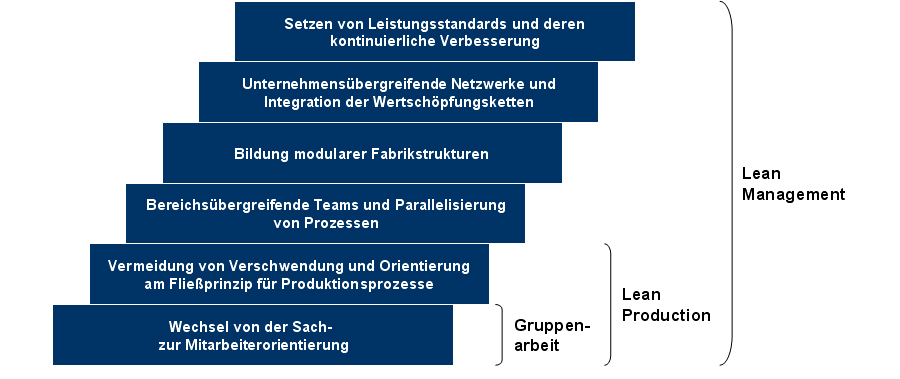

Lean Production is the most wellknown form of Lean Management Waste is continuously reduced and eliminated in order to maximise the proportion of value adding work Work is carried out in accordance with documented standards that are regularly verified and improved a required. Das Volkswagen Stammwerk Wolfsburg ist auf dem Weg zu mehr Produktivität und Effizienz mit beispielhaftem Veränderungstempo unterwegs und gewann deshalb den. $ 499 Lean Six Sigma Project Charter Online Training (Complete with Certification) $ 499 Lean Six Sigma SIPOC Diagram Online.

How Lean Six Sigma Saved $4 Million at UCSD Medical Center, Featuring Lily Angelocci;. The Process Study Sheet is used to define and record the time for work elements in a process Before timing, opbserve and list the work elements required to produce one element Then observe and define the actual time required for each individual work elementTiming TipsCollect real times at the processPosition yourself so you can see the operator's hand motionsTime each work element. Beratungsbeispiel Lean Production Erhöhung der Overall Equipment Effectivness (Gesamtanlageneffektivität) Ein Unternehmen, das mit mehreren Anlagen und Maschinen elektronische Komponenten fertigt, stand aufgrund der nicht ausreichenden Anlagenkapazität vor der Entscheidung, eine neue Produktionsanlage zu kaufen.

Einstein is quoted as having said that if he had one hour to save the world he would spend fiftyfive minutes defining the problem and only five minutes finding the solution This quote illustrates an important point before jumping right into solving a problem, we should step back and invest time and effort to improve our understanding of it. Einstein is quoted as having said that if he had one hour to save the world he would spend fiftyfive minutes defining the problem and only five minutes finding the solution This quote illustrates an important point before jumping right into solving a problem, we should step back and invest time and effort to improve our understanding of it. Key Performance Indicators for Production Monitoring Posted in Canada, Education, General on 22/04/14 Lean manufacturing focuses on eliminating sources of waste and continuously looking for ways to improve the organization In order to assess and measure the processes, organizations often use Key Performance Indicators (KPIs).

Jürgen Reichardt, Christian Gottswinter, and Candy Patrick Schulze (10) Lean Production in der Fabrikplanung am Beispiel eines Automobilzulieferers ZWF Zeitschrift für wirtschaftlichen Fabrikbetrieb Vol 105, No 4, pp. Lean is a suite of four complementary, interconnected principles, each geared towards increasing value to the customer by improving efficiency By applying these simple principles, any business in any sector can not only provide a better service or product to their end users, but also make fundamental, sustainable improvements in profitability. And “lean startup,” a set of principles and practices developed in Silicon Valley over the past decade that help entrepreneurs and intrapreneurs launch new products and services 1 Think of lean production as a way to maximize the efficiency.

The core idea of lean manufacturing is actually quite simplerelentlessly work on eliminating waste from the manufacturing process So what is waste?. Lean has two distinct strains “lean production” (also known as “lean manufacturing”), a structured method first developed by Toyota more than 25 years ago that applies to complex processes like manufacturing, logistics, and health services;. It's easy to remember the 7 Wastes of Lean with the acronym TIMWOOD Learn what each letter stands for and how to counteract each waste TIMWOOD stands for the Seven Wastes of Lean transportation, inventory, motion, waiting, overproduction, overprocessing, and defects.

Poka yoke is a lean manufacturing tool that refers to “mistakeproofing” or “errorproofing” a process It was originally coined by Shigeo Shingo in the 1960s and implemented at Toyota as part of the Toyota Production System (TPS). But if you want to create real value and jobs that value people, you must think hard about how your people are working every day That’s because the essence of lean thinking is about the work Lean thinking and practice mean working on the work the valuecreating work that occurs on the frontlines of your enterprise. Waste is defined as any activity that does not add value from the customer’s perspective.

Lean manufacturing, also known as lean production or simply lean, is a management philosophy based on the idea of maximizing efficiency without compromising productivity This approach originated in Japan at Toyota Motor Company Western manufacturers began learning about lean in the early 1990s. The famous shoe and clothing giant has also adopted lean manufacturing techniques Much like other businesses, Nike saw less waste and higher customer value, but also some unforeseen benefits Lean manufacturing was shown to reduce poor labor practices in their overseas manufacturing plant by up to fifteen percent This was mainly due to lean manufacturing valuing the worker more than previous labor practices. Even if your early use cases lean toward a specific department (operations, quality assurance, supply chain management, etc), manufacturing is so holistic that it always helps to have the option to tap into your comprehensive data Accurate and Consistent Data.

Home6 16 Specht Fabriksoftware

Lean Production Erfordert Umdenken Bild 1 6

Lean Beratung Factory Consultants Gmbh Fabrikplanung Und Lean Management Fur Produzierende Unternehmen

Lean Production Beispiel のギャラリー

Lean Production Definition Erklarung Beispiele Ubungsfragen

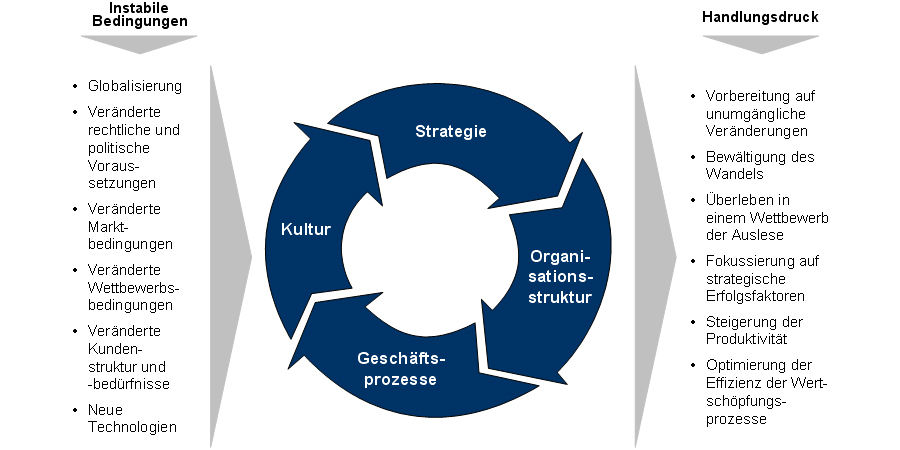

Lean Management Und Kein Ende Auf Dem Weg Zum Lean Business System Mit Der Change Formel

Rustoptimierung Mit Smed Lean Management Beratung

Wi Uni Giessen De Gi Dl Showfile Schwickert Apap Wi Gi 10 04 Pdf Download Gesch Tzt Pdf

Lean Production Goes Digital Was Andert Sich Fur Die Industrie

Lean Production Dede Syaehumishbah Ppt Herunterladen

90 Vsm Ideas Value Stream Mapping Lean Six Sigma Lean Manufacturing

Commitment In Geschaftsbeziehungen Das Beispiel Lean Production Neue Sollner Albrecht Amazon De Bucher

Lean Six Sigma Lean Und Six Sigma Seminare

Kompetenz Fur Lean Management Pdf Kostenfreier Download

Sauberkeit Macht Spass Graphic Consult

Schlanke Produktion Wikipedia

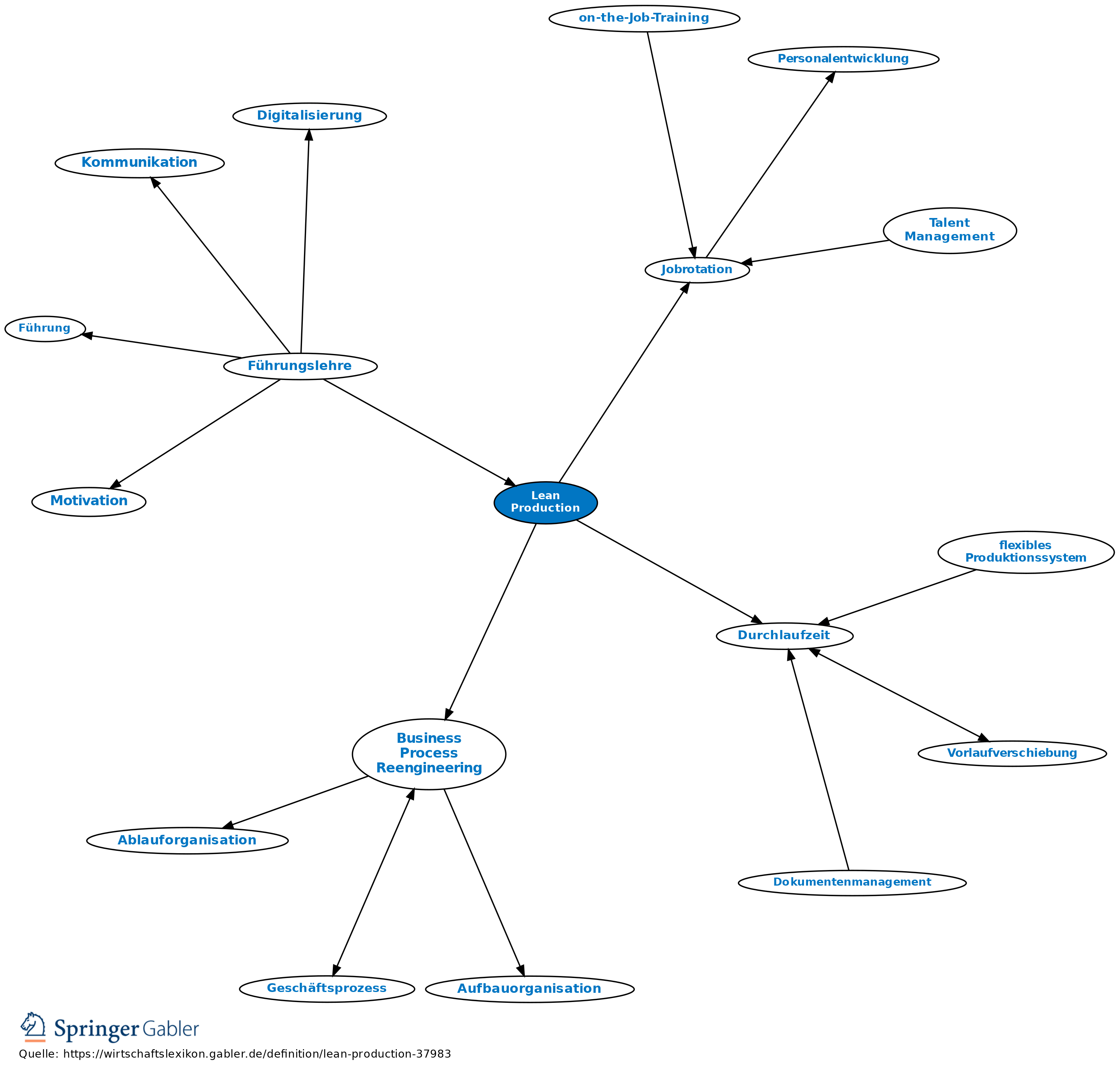

Lean Production Definition Gabler Wirtschaftslexikon

Lean Management Und Lean Production

Lean Production Definition Konzept Und Beispiel

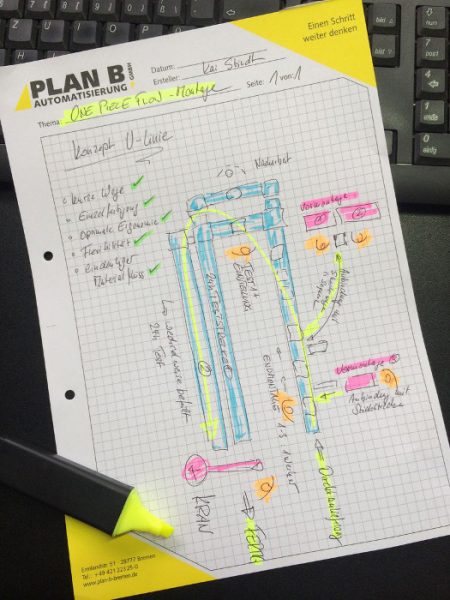

One Piece Flow Beispiel Aus Der Praxis

Wie Lean Production Menschlich Wird

Www Iwex De Download File File Id 117 File Code 4d131a2507

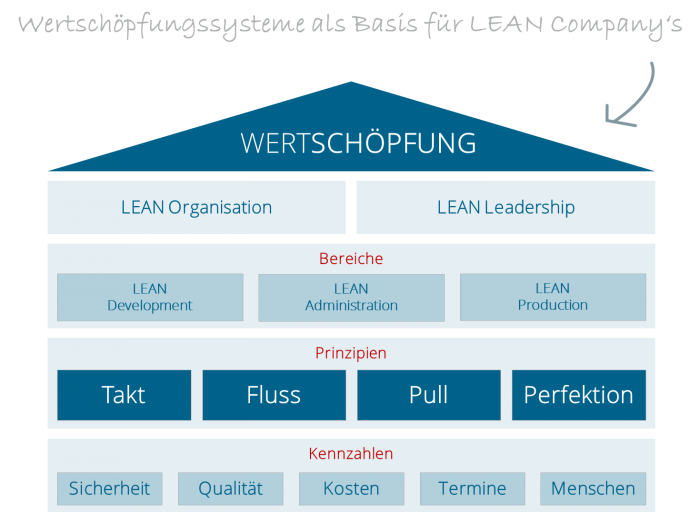

Ganzheitliche Produktionssysteme

Lbc8cwvxe4py5m

Lean Production Manager Tuv Sud Akademie

Lean Production Und Lean Management Herzlich Willkommen

Lean Administration Instrumente Der Lean Production Grin

Was Ist Lean Logistik Strategie Der Effizienz Mecalux De

Lean Production Begriffe Auf Einen Blick Item Blog

Gut Durchgetaktet Mit Lean Production All Electronics

Kanban System Einfach Erklart So Geht Lean Production

Kaizen Massnahmen Fur Die Schlanke Produktion Asprova Ag

Lean Beratung Factory Consultants Gmbh Fabrikplanung Und Lean Management Fur Produzierende Unternehmen

Waste Of Overprocessing Causes Costs Examples Solutions Symptoms

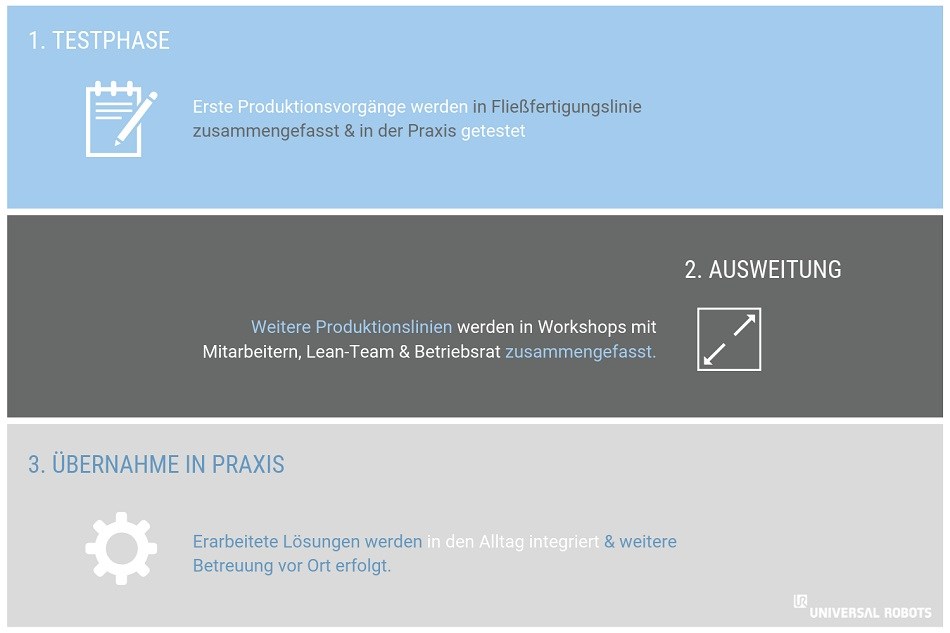

Lean Production In Der Elektronikbranche Universal Robots

Was Ist Lean Management Definition Methoden Ifm

Prof Dr Frank Balsliemke Hochschule Osnabruck

Muda 7 Abfalle Nach Lean Manufacturing Sesa Systems

Pdf Roadmap For The Implementation Of Lean Production Systems Semantic Scholar

Der Kunde Hat Konjunktur So Brechen Lean Production Und Intelligente Plattformen Klassische Produktionszyklen Auf Digitus

Home5 16 Nyhuis Fabriksoftware

Lean Production Und Lean Management Herzlich Willkommen

Analyzing Industry 4 0 Models With Focus On Lean Production Aspects Springerlink

Lean Production Dede Syaehumishbah Ppt Herunterladen

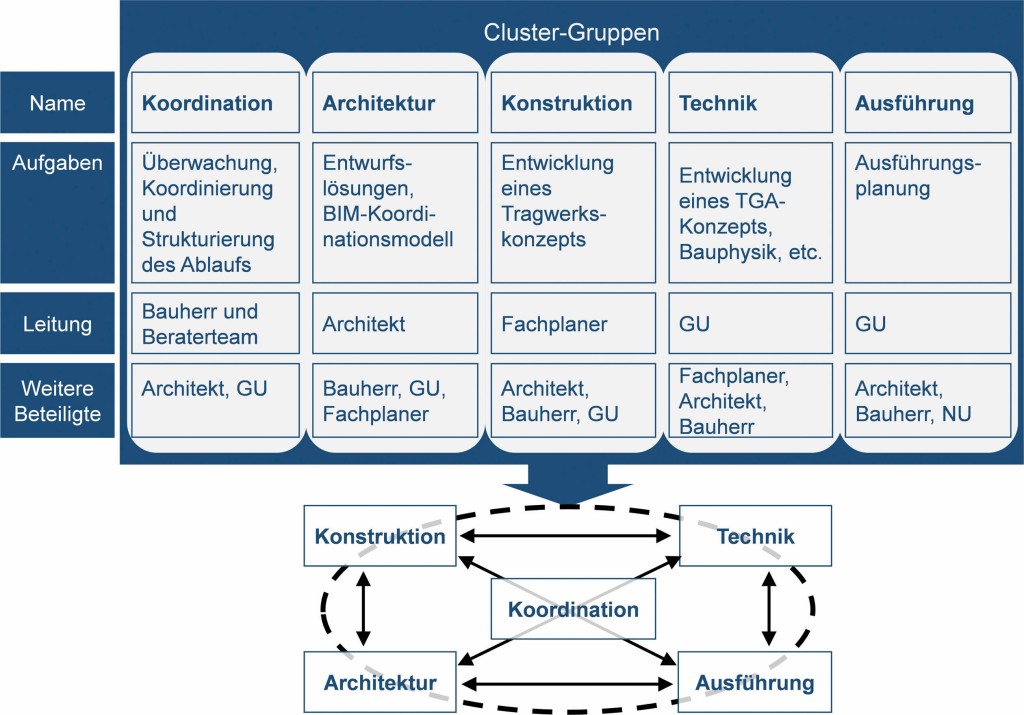

Wechselwirkungen Zwischen Lean Construction Und Der Arbeitsmethode Bim Am Beispiel Der Bim Ingenieur De

Genese Verlauf Und Niedergang Von Managementmoden Aus Sicht Des Neo Institutionalismus Am Beispiel Der Lean Production German Edition Hubrich David Karl Amazon Com Books

Leanproductionmanufacturing Span Class B Floatr Exp Img Downimg B Hide Span Span Class B Floatr Exp Img Upimg Span Div Class Datavc Div Class B Vpanel B Divsec Div Class B Mtext Overview Div Div Div Div Div Div Div Class Acc

Lean Production Am Praktischen Beispiel Erfahren Prozesstechnik Portal

Schmersal Deutschland Lean Production

Lean Management In Der Medienbranche Das Beispiel C H Beck Nordlingen

Lean Production Firma24 7

Digital4industry Lu Wp Content Uploads 19 07 Ipl Fedil Presentation Pdf

Lean Development Wikipedia

Lean Production Beratung Und Consulting Targus

Lean Production Lean Manufacturing Schlanke Produktion Quality De

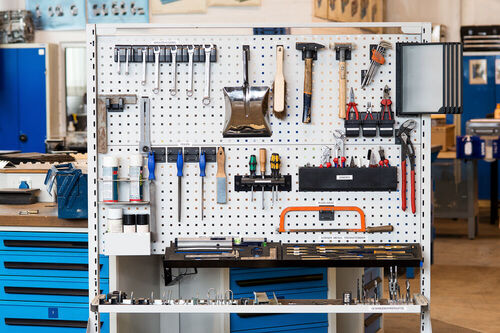

Methode 5s Erklarungen Beispiel Lean Sesa Systems

What Is The Hoshin Kanri X Matrix

Obeya Room Toyota Way Visual Management Lean Enterprise Innovation Management

Toyota Production System Tps House Of Lean World S Best Manufacturing System Youtube

Manage It It Strategien Und Losungen

Analyzing Industry 4 0 Models With Focus On Lean Production Aspects Springerlink

Lean Production In Der Fertigenden Industrie Pdf Kostenfreier Download

Lean Production Beratung B P Gruppe

Lean Management Und Lean Production

Lean Production Mudamasters

Toyota Produktionssystem Wikipedia

Lean Management Und Lean Production

Lbc8cwvxe4py5m

Low Cost Automation Geringe Kosten Hohe Produktivitat

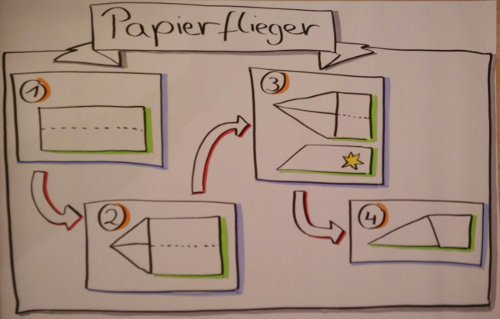

Kanban Papierflieger Spiel Steemit

Zehn Typische Lean Bugs Die Erfolgreiches Lean Management Verhindern Leanpublishing Leanbase

Bol Com Mikropolitik Im Lean Management David Pieper Boeken

Lean Beratung Factory Consultants Gmbh Fabrikplanung Und Lean Management Fur Produzierende Unternehmen

Home6 16 Specht Fabriksoftware

Die 7 Verschwendungsarten In Lean Wie Sie Ihre Ressourcen Optimieren

Lean Production Das Prinzip Der Schlanken Produktion Industrie Wegweiser

Die Rolle Von Kanban Fur Die Lean Production Item Blog

Symbole Und Kennzahlen Der Wertstromanalyse Wertstromanalyse Value Stream Mapping Business Wissen De

Lean Office Lean Management In Buro Und Verwaltung Unternehmensberatung Axel Schroder

Www Boeckler De Pdf P Fofoe Wp 097 18 Pdf

Lean Production Grundlagen Und Hilfsmittel Fur Eine Schlanke Produktion Unternehmensberatung Axel Schroder

Lean Management Definition Prinzipien Und Methoden

Lean Manufacturing Am Beispiel Der Goethe Ag

Lean Games Spielerisch Zu Mehr Effizienz Unternehmensberatung Axel Schroder

Six Sigma Infocenter Six Sigma College

Schlanke Produktion Lean Production Und Lean Manufacturing It Production

Home5 16 Nyhuis Fabriksoftware

Lean Management Fallbeispiele Lean Management Beratung

Lean Production Grundlagen Und Hilfsmittel Fur Eine Schlanke Produktion Unternehmensberatung Axel Schroder

Lean Manufacturing Indeva Group

Lean Production Dede Syaehumishbah Ppt Herunterladen

One Piece Flow Der Direkte Weg Zur Lean Production Item Blog

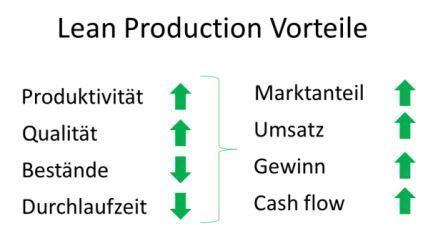

Lean Production Vorteile Kennen Und Heben

Lean Production Vom Wertstrom 4 0 Zur It Zielarchitektur

5gqipqx1 Eq5 M

Leanhealth Ch What Tool Spaghetti Diagramm

Lean Production Methoden Schlanke Produktion Pdf Kostenfreier Download

How To Create An Effective Daily Management System Planet Lean

Schmersal Deutschland Lean Production

Lean Production

Lean Production Simulation Beispiel 1 Leancom Gmbh Youtube