Apqp Ppap

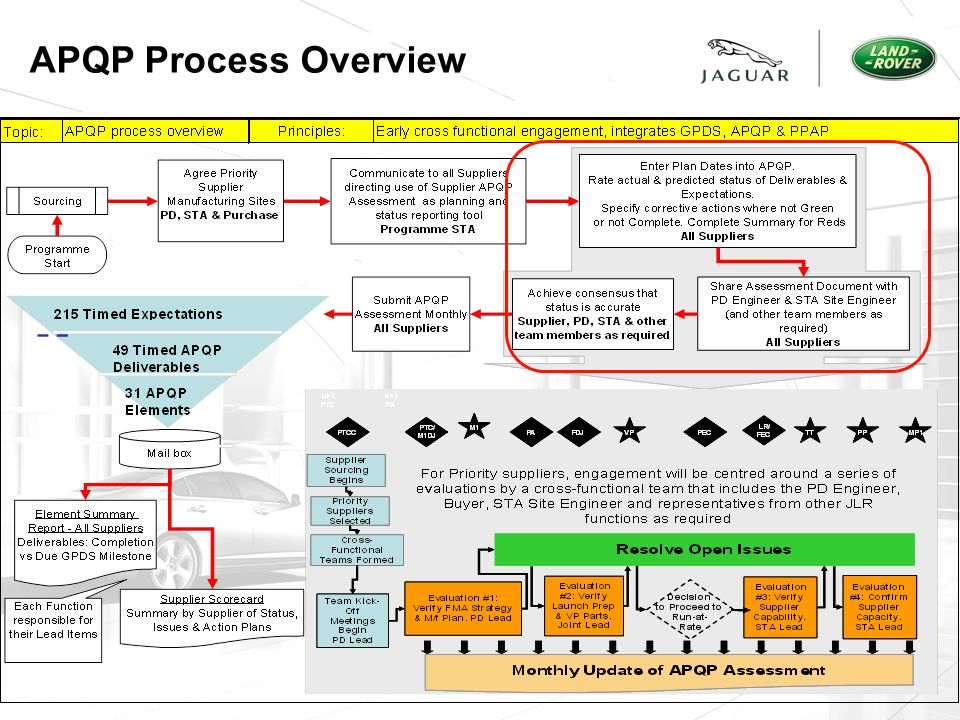

APQP – Advanced Product Quality Planning is a structured approach that is used to design and develop the product and process to meet customer needs and expectations Advanced Product Quality Planning tool is extensively used by Automotive industries to assure quality and performance through effective planning.

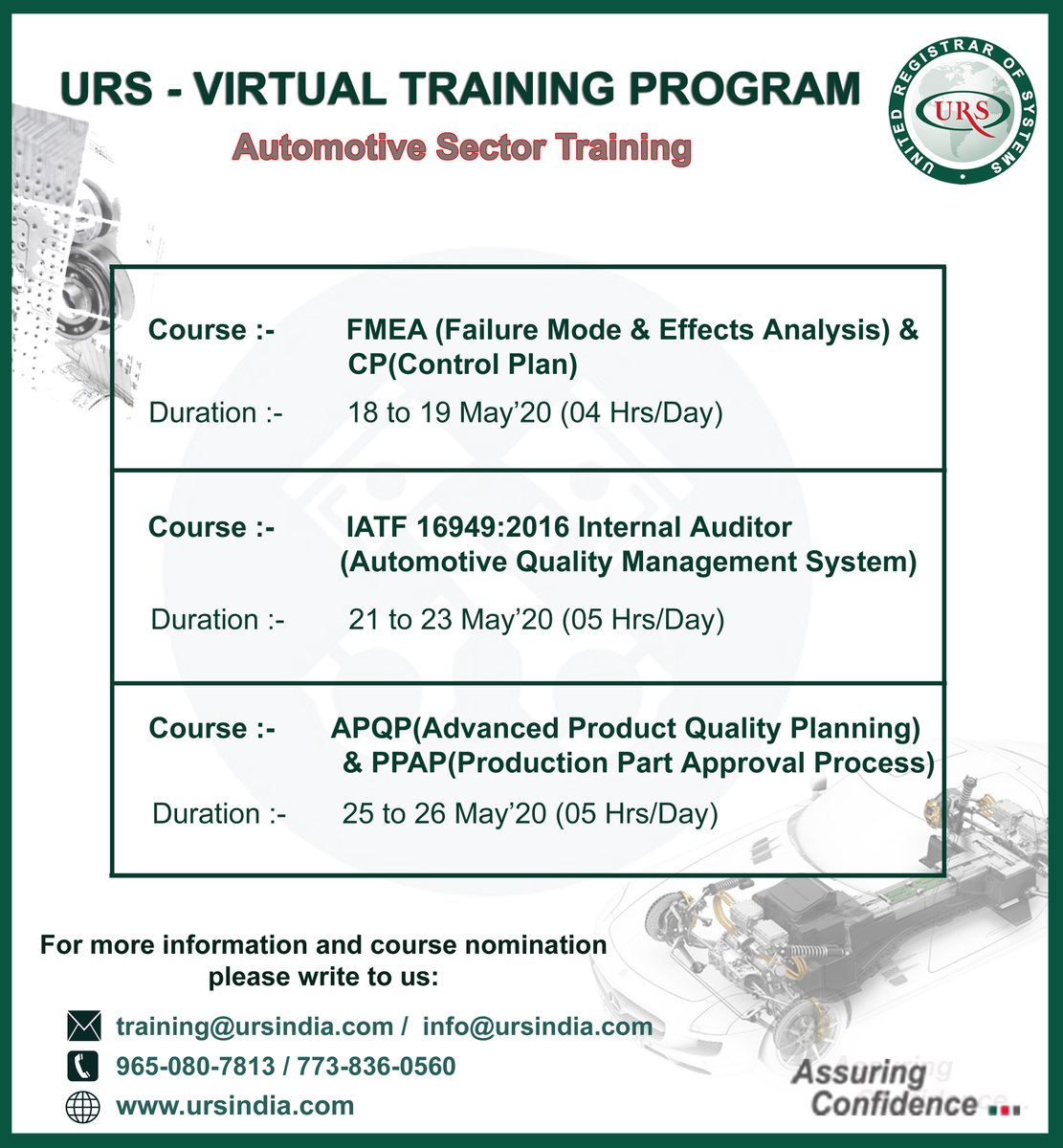

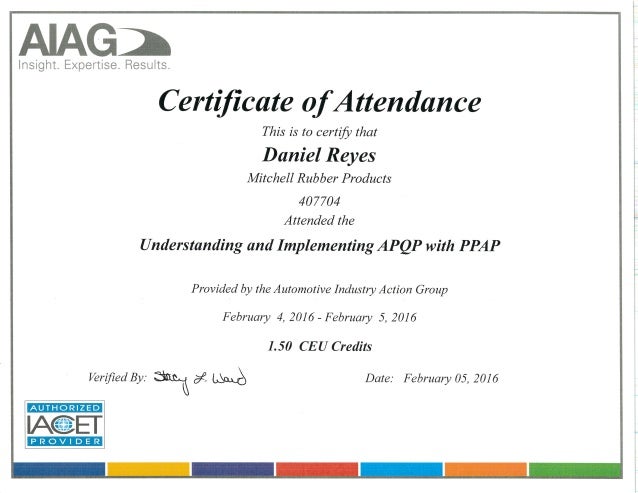

Apqp ppap. Advanced Product Quality Planning (APQP) is a structured method for defining and executing the actions necessary to ensure a product satisfies the customer APQP is program and supplierled and is required of all system, subsystem and component manufacturing locations This includes both internal and external suppliers to Ford. Statistical Process Control (SPC) Measurement Systems Analysis (MSA) Please note, only DFMEA or PFMEA can be taken in a single, one week session These courses will cover the AIAG FMEA 4 th Edition methodology. Each of the Core Tools to help evaluate your current understanding of APQP/PPAP, FMEA, MSA and SPC, and determine opportunities for additional training AIAG Production Part Approval process PPAP 4th Edition Aiag Ppap Manual Pdfpdf Free download Ebook, Handbook, Textbook, User Guide PDF files on the internet quickly and easily APQP training.

Author Jarold March/Bengt Ottosson Last modified by r0454 Created Date 8/4/1999 PM Title PPAP formsxls Other titles 4th Edition Truck PSW 4th Edition PSW Numbered 4th Edition PSW Instructions 4th Edition AAR 4th Edition AAR Numbered 4th Edition AAR instructions 4th Edition Dimensionnal result 4th Edition Material TR 4th Edition Performance TR '4th Edition AAR'!Zone_d. Production Part Approval Process Part Submission Warrant (PSW) The goal of APQP is to facilitate communication between the design team and the rest of the organization Designing is a company function, but often it is done in silos, only to discover during the transition that there are problems that are too late to address. Customize and configure requirements to meet unique needs Define your company's APQP/ PPAP required elements, designate whether they are optional or required, and determine how to satisfy these requirements (ie, uploaded documentations or a user signature) Provide examples and templates for your suppliers to utilize.

How PPAP affects APQP If the PPAP results don't meet customer expectations, that usually means the APQP process isn't working properly The test for both APQP and PPAP is a production trial run If the finished trial product includes defective parts, the manufacturer has to go over the supply chain and find out where PPAP or APQP went wrong. APQP – PPAP – SPC – MSA – FMEA 3 Days, 8 am 5 pm Suppliers to the automotive industry know that Core Quality Tools is synonymous with Customer Specific Requirements The Customers’ Specific Requirements include various degrees and "twists and turns" of the Core Tools. APQP/PPAP Manager Pricing Overview APQP/PPAP Manager pricing starts at $ as a onetime payment They do not have a free version APQP/PPAP Manager does not offer a free trial.

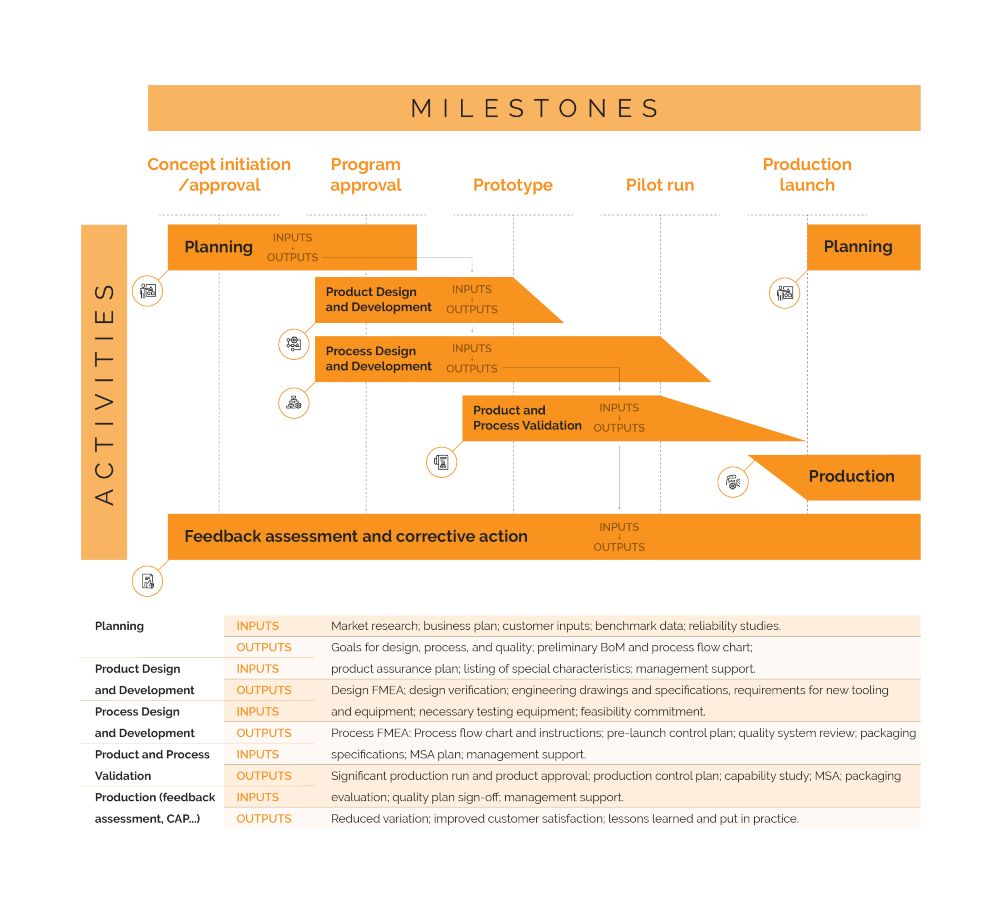

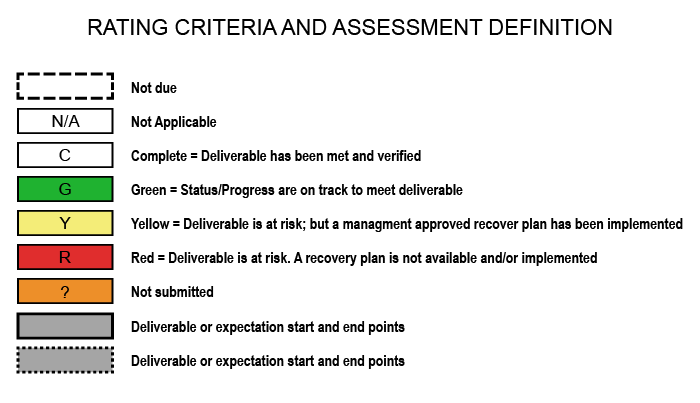

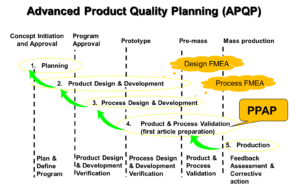

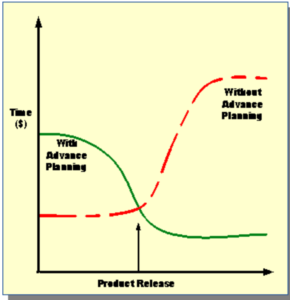

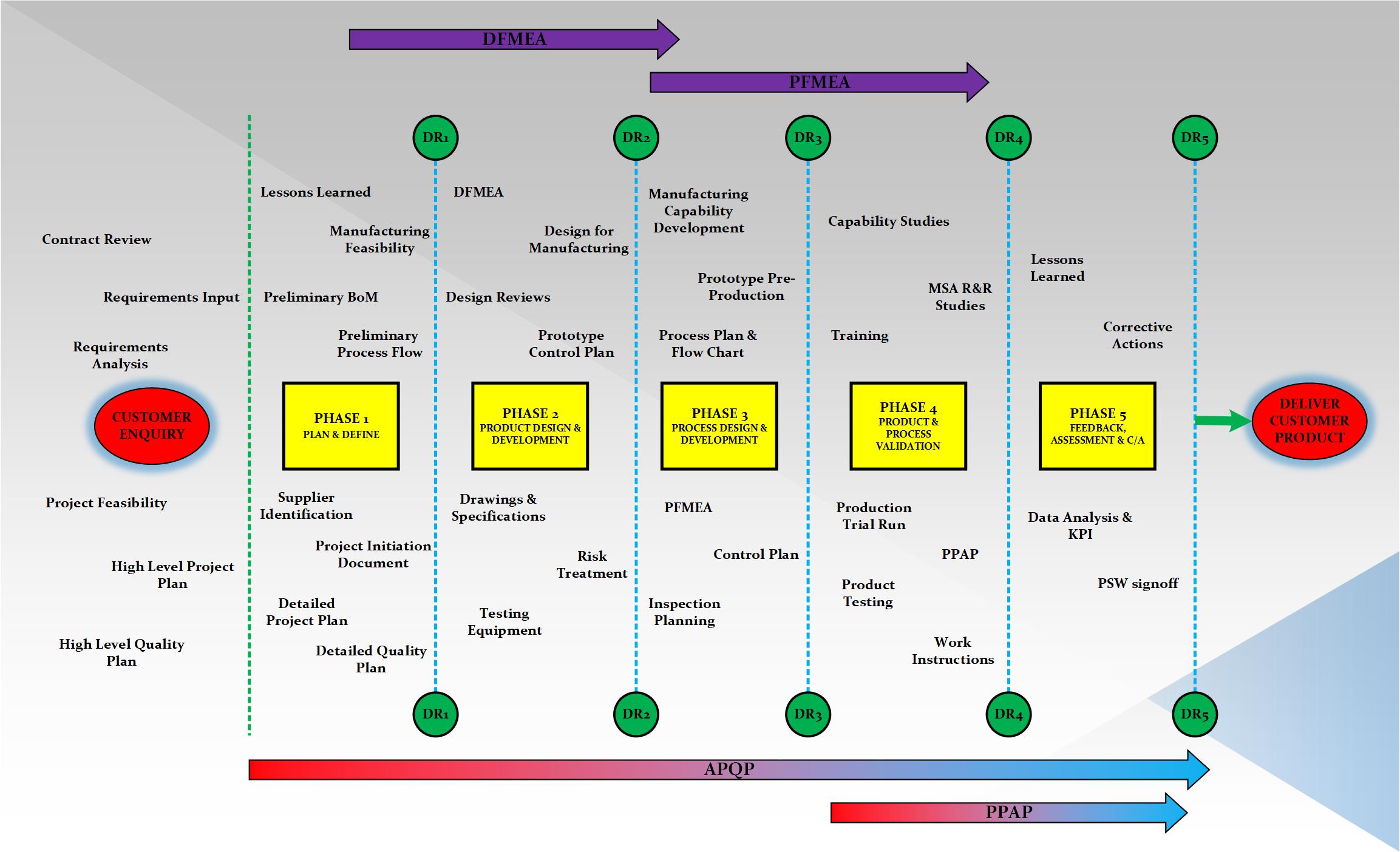

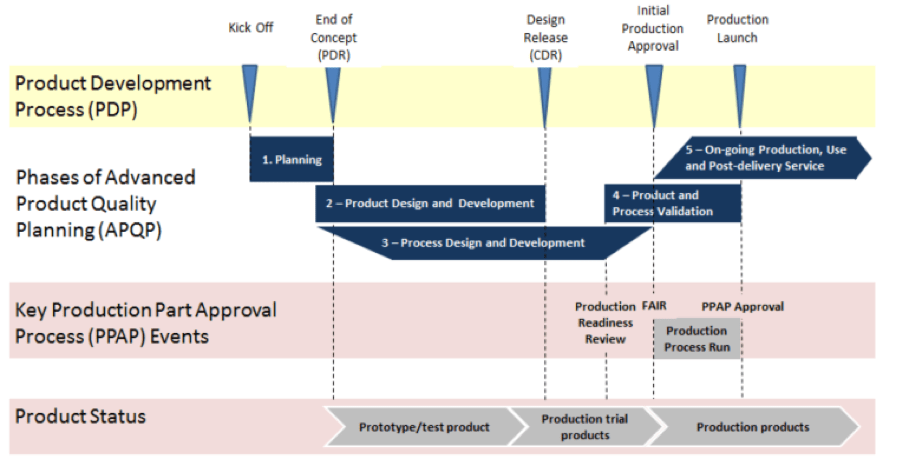

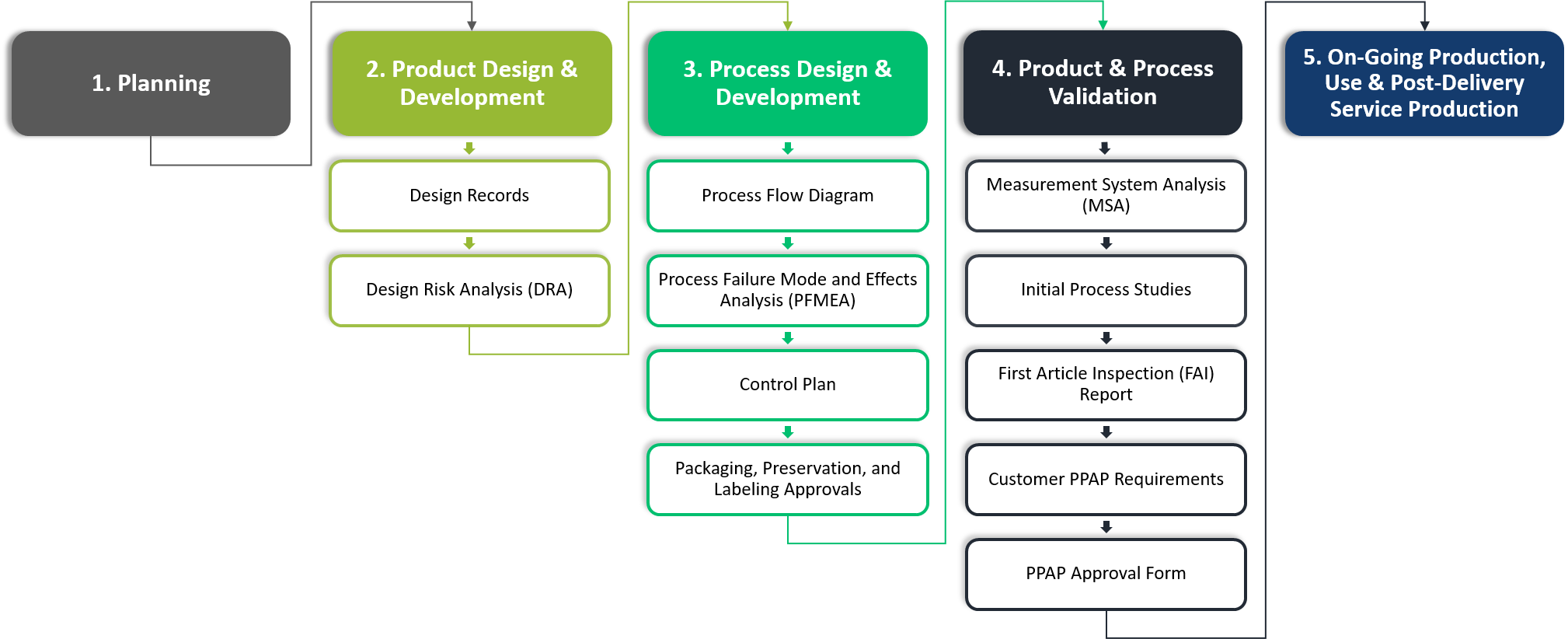

APQP has five phases (see Figure 1) starting with conceptual product needs and extending throughout the product life cycle Figure 1 Product Development Process and Advanced Product Quality Planning (conceptual illustration) PPAP Approval is Gate 4 of APQP and used to validate that the production process has demonstrated. APQP is a process that happens during the product development lifecycle to facilitate transparent communication and feedback throughout the supply chain This process allows suppliers to detect errors early on, incorporate customer feedback, and deliver high quality products PPAP is an output of APQP. APQP (Advanced Product Qualit Planning) or PPAP is a Structured method in defining and establishing steps necessary to ensure that a product satisfies the customer.

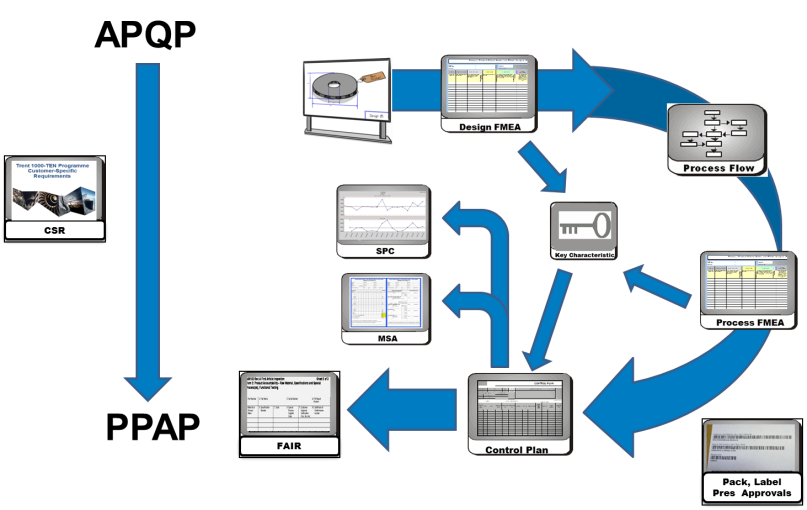

APQP is the entire quality planning process from designing a concept through PPAP (see below) This typically includes, but is not limited to, Design/Process FMEAs, Measurement System Analysis, capability studies, Control Plans and PPAP. 9145 applies Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) to Product Developmentin the Aviation Space And Defense (AS&D) industry 5Phase Product Development Process 1 Planning 2. The Automotive Industry Action Group (AIAG) is a nonprofit association of automotive companies founded in 19 Main content of APQP APQP serves as a guide in the development process and also a standard way to share results between suppliers and automotive companies.

Course Description The AS9145 Aerospace standard was created to define the aviation, space, and defense process requirements for Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) The APQP process defines a methodology for ensuring that the product development processes deployed throughout the aviation, space, and defense industries are fully integrated. Blue Ocean APQP & PPAP / NPI system is a robust, easytouse system designed to effectively manage the whole cycle of NPI process Below are the key features of this system Work flow control whereby user has flexibility to change the work as per specific customer requirements;. Advanced Product Quality Planning (APQP) is a structured method for defining and executing the actions necessary to ensure a product satisfies the customer APQP is program and supplierled and is required of all system, subsystem and component manufacturing locations This includes both internal and external suppliers to Ford.

Although APQP is generally associated with the automotive industry, the quality planning processes can be applied to all industries The “QualityOne” APQP approach is considered to be BestinClass, because it is easily communicated to design teams and suppliers The Production Part Approval Process (PPAP) involves the management of many. APQP (Advanced Product Qualit Planning) or PPAP is a Structured method in defining and establishing steps necessary to ensure that a product satisfies the customer. APQP has five phases (see Figure 1) starting with conceptual product needs and extending throughout the product life cycle Figure 1 Product Development Process and Advanced Product Quality Planning (conceptual illustration) PPAP Approval is Gate 4 of APQP and used to validate that the production process has demonstrated.

How PPAP affects APQP If the PPAP results don't meet customer expectations, that usually means the APQP process isn't working properly The test for both APQP and PPAP is a production trial run If the finished trial product includes defective parts, the manufacturer has to go over the supply chain and find out where PPAP or APQP went wrong. AS9145 APQP & PPAP The AS9145 Aerospace standard was created to establish the aviation, space, and defense (ASD) process requirements for two of the Aviation Core Tools Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP). Although APQP is generally associated with the automotive industry, the quality planning processes can be applied to all industries The “QualityOne” APQP approach is considered to be BestinClass, because it is easily communicated to design teams and suppliers The Production Part Approval Process (PPAP) involves the management of many.

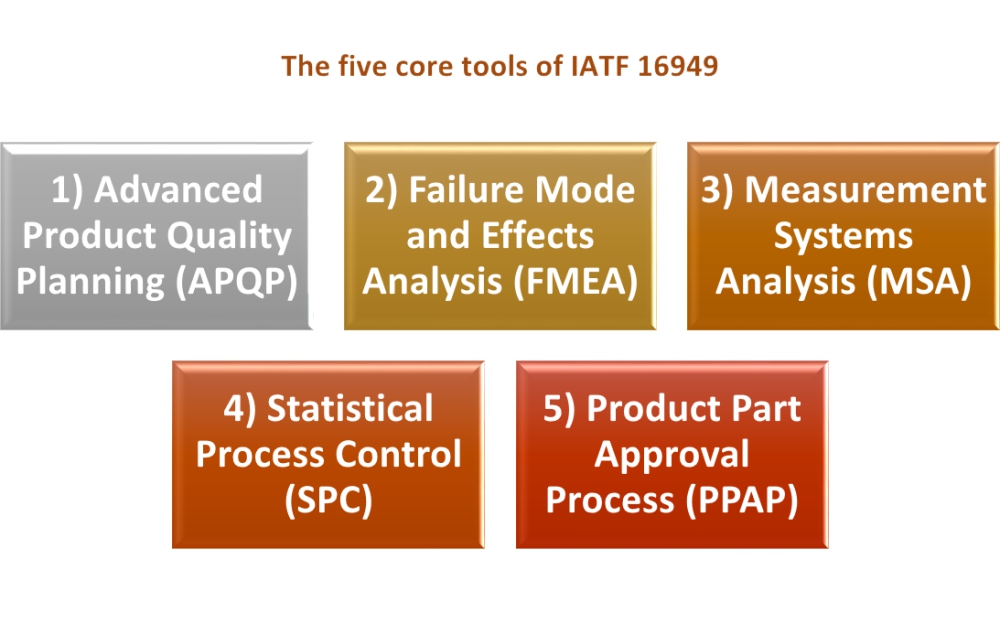

Advanced Product Quality Planning (APQP) is a structured process aimed at ensuring customer satisfaction with new products or processes APQP has existed for decades in many forms and practices Originally referred to as Advanced Quality Planning (AQP), APQP is used by progressive companies to assure quality and performance through planning. PPAP (Production Part Approval Process) is one component of APQP (Advanced Product Quality Planning). The Automotive Quality Core Tools are the building blocks of an effective quality management system They include Advanced Product Quality Planning & Control Plan (APQP), Production Part Approval Process (PPAP), Failure Mode and Effects Analysis (FMEA), Statistical Process Control (SPC) and Measurement System Analysis (MSA).

Why PSA adopted APQP & PPAP?. IAQG Holds Webinar Series on APQP and PPAP September 9, 19 IAQG Communications IAQG, SCMH Join the IAQG for a series of webinars, given by the Product and Supply Chain Improvement Team on Advanced Product Quality Planning (APQP) and Production Part Approval (PPAP) as defined in 9145 The sevenpart webinar series is free to all. APQP/PPAP Approval Record Once created, an APQP record can be saved and signed by both its Supplier and its Customer "Print" and "Void" buttons are also available in the topleft of each page (The Void option will permanently cancel the APQP record, so it should only be used when a record is no longer required, or needs to be replaced).

APQP provides a structure for planning, defining, and completing necessary activities to produce products that are ontarget for customer needs and expectations The program requires the use of standard quality tools, such as FMEA, SPC, PPAP, and comprehensive control plans for effectiveness. Why PSA adopted APQP & PPAP?. • Case studies video on APQP, PPAP, FMEA, Process Capability, MSA • Formats 3 You will be also given opportunity to clear you doubt on relevant subject with our expert (EMail) 4 Once ready you will intimate us to send you questionnaire/ link (Objective and Descriptive) for the test 5.

The production part approval process (PPAP) manual;. PRODUCT REALIZATION (APQP/PPAP) SOFTWARE AQuA Pro® is the most effective tool for Advance Product Quality Planning This is the software that started it all In the mid 1980s AQuA Pro® became the very first Advance Product Quality Planning (APQP) software package and a bestseller for Omnex Systems Now we have introduced an all web version. → APQP Advanced Product Quality Planning is a structured approach that is used to design and develop the product and_process to meet customer needs and expectations → Advanced Product Quality Planning tool is extensively used by Automotive industries to assure quality and performance through effective planning.

From the definitions, it is apparent that PPAP is the result of correct use of APQP PPAP is all about collecting data and information created by the APQP phase and presenting the worked out design to the customer for response and sanction In fact, the Act stage of APQP is, in essence, PPAP. The five phases of APQP itself;. 4 The 5 Phases of the PSA APQP 5 The APQP grid 6 Suppliers consultation, planning & defining the program 7 Product development 8 Achievement of specific tools 9 Checking Product / Process 10 Rampup 11 Implementing the PCP during the APQP & PPAP phase 12 Steering the rules of the APQP 13 Summary.

• Case studies video on APQP, PPAP, FMEA, Process Capability, MSA • Formats 3 You will be also given opportunity to clear you doubt on relevant subject with our expert (EMail) 4 Once ready you will intimate us to send you questionnaire/ link (Objective and Descriptive) for the test 5. • Case studies video on APQP, PPAP, FMEA, Process Capability, MSA • Formats 3 You will be also given opportunity to clear you doubt on relevant subject with our expert (EMail) 4 Once ready you will intimate us to send you questionnaire/ link (Objective and Descriptive) for the test 5. APQP is the entire quality planning process from designing a concept through PPAP (see below) This typically includes, but is not limited to, Design/Process FMEAs, Measurement System Analysis, capability studies, Control Plans and PPAP.

APQP – Advanced Product Quality Planning is a structured approach that is used to design and develop the product and process to meet customer needs and expectations Advanced Product Quality Planning tool is extensively used by Automotive industries to assure quality and performance through effective planning APQP is one of the important tool among the Five Core Tools of IATF Standard. APQP/PPAP Manager empowers organizations to manage people and processes more effectively, while streamlining the entire Project Management Lifecycle Monitors the EwQIMS project status;. APQP has five phases (see Figure 1) starting with conceptual product needs and extending throughout the product life cycle Figure 1 Product Development Process and Advanced Product Quality Planning (conceptual illustration) PPAP Approval is Gate 4 of APQP and used to validate that the production process has demonstrated.

Helps you manage EwQIMS with ease;. 4 The 5 Phases of the PSA APQP 5 The APQP grid 6 Suppliers consultation, planning & defining the program 7 Product development 8 Achievement of specific tools 9 Checking Product / Process 10 Rampup 11 Implementing the PCP during the APQP & PPAP phase 12 Steering the rules of the APQP 13 Summary. Advanced product quality planning (APQP) is a system for keeping product quality and customer satisfaction high APQP started in the auto industry in the 1980s as a way for car manufacturers to reduce problems with new models The production part approval process (PPAP) applies similar standards to manufacturers' supply chains.

APQP provides a structure for planning, defining, and completing necessary activities to produce products that are ontarget for customer needs and expectations The program requires the use of standard quality tools, such as FMEA, SPC, PPAP, and comprehensive control plans for effectiveness. APQP provides a structure for planning, defining, and completing necessary activities to produce products that are ontarget for customer needs and expectations The program requires the use of standard quality tools, such as FMEA, SPC, PPAP, and comprehensive control plans for effectiveness. APQP – PPAP – SPC – MSA – pFMEA & VDA pFMEA 3 Days, 8 am 5 pm Suppliers to the automotive industry know that Core Quality Tools is synonymous with Customer Specific Requirements The Customers’ Specific Requirements include various degrees of twists and turns for requirements of the Core Quality Tools.

SoftExpert APQPPPAP SoftExpert Advanced Product Quality Planning, or APQP, is a software developed to automate the methods for managing the development and change of products It serves as a guide in the product development process, while also standardizing the methods of sharing results between suppliers and manufacturers. 4 The 5 Phases of the PSA APQP 5 The APQP grid 6 Suppliers consultation, planning & defining the program 7 Product development 8 Achievement of specific tools 9 Checking Product / Process 10 Rampup 11 Implementing the PCP during the APQP & PPAP phase 12 Steering the rules of the APQP 13 Summary. Shana Deering is an APQP/PPAP Subject Matter Expert and trainer for Verify Inc Shana has over 15 years’ experience in A&D and the initiation of these processes for the supply chain For more information on APQP/PPAP in the Aerospace and Defense supply chain please contact Hank Hagedoorn Director, Marketing Verify Inc.

Customize and configure requirements to meet unique needs Define your company's APQP/ PPAP required elements, designate whether they are optional or required, and determine how to satisfy these requirements (ie, uploaded documentations or a user signature) Provide examples and templates for your suppliers to utilize. PPAP is a Part of APQP From the definitions, it is apparent that PPAP is the result of correct use of APQP PPAP is all about collecting data and information created by the APQP phase and presenting the worked out design to the customer for response and sanction In fact, the Act stage of APQP is, in essence, PPAP. PPAP Manager is a cloudbased solution that streamlines and automates the Production Part Approval Process, saving up to 50% of the time, reducing the cost of poor quality, ensuring compliance with industry standards, and improving your product’s quality.

PPAP as part of aPQP The PPAP package is closely related to the Advanced Product Quality Planning Process (APQP) used during the design and development of new vehicles to reduce the risk of unexpected failure Advanced product quality planning (or APQP) is a framework of procedures and techniques used to develop products in industry, integrating quality tools with management functions. APQP – PPAP – SPC – MSA – pFMEA & VDA pFMEA 3 Days, 8 am 5 pm Suppliers to the automotive industry know that Core Quality Tools is synonymous with Customer Specific Requirements The Customers’ Specific Requirements include various degrees of twists and turns for requirements of the Core Quality Tools. Why PSA adopted APQP & PPAP?.

The production part approval process is an output of APQP processes and techniques PPAP highlights the evidence established through the APQP In addition, APQP has become an important factor for aerospace & defense industry segments as it's a key component of the AS9145 standard. 9145 applies Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) to Product Development in the Aviation Space And Defense (AS&D) industry 5Phase Product Development Process 1 Planning 2 Product Design and Development 3 Process Design and Development 4 Product and Process Validation 5. The 9145 standard was created to define the aviation, space, and defense process requirements for Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) The APQP aspects of this standard define a methodology for ensuring that the product development processes deployed throughout the aviation, space, and defense.

Capability to assign responsibility for both NPI leader and members. Home / Courses / Quality Tools & Techniques / APQP & PPAP APQP Many organisations are struggling with the concept of advanced quality planning and how to incorporate this methodology into existing framework Published jointly by DaimlerChrysler, Ford and General Motor, advanced product quality planning is required in the IATF Quality Systems Requirements manual, but it can be used for. APQP/PPAP Manager is our incredibly practical software that facilitates any addition, edit, or monitoring needed for projects.

Production Part Approval Process (PPAP) is a valuable tool for establishing confidence in component suppliers and their production processes In today’s competitive manufacturing environment controlling cost and maintaining a high level of quality have become vital to a company’s success. Implement the APQP process, develop control plans and complete the PPAP efficiently and effectively In this twoday workshop participants will acquire the skills necessary to complete all five Advanced Product Quality Planning (APQP) phases from "voice of the customer" through final output, including control plan methodology and Production. Production Part Approval Process (PPAP) Process Failure Mode Effects Analysis (PFMEA) and Control Plans;.

APQP (Advanced Product Qualit Planning) or PPAP is a Structured method in defining and establishing steps necessary to ensure that a product satisfies the customer. SoftExpert APQPPPAP SoftExpert Advanced Product Quality Planning, or APQP, is a software developed to automate the methods for managing the development and change of products It serves as a guide in the product development process, while also standardizing the methods of sharing results between suppliers and manufacturers.

Fillable Online Response Form Apqp Ppap Elcinacom Fax Email Print Pdffiller

Advanced Product Quality Planning Apqp And Production Part Approval Process Ppap Online Presentation

Apqp Ppap Key Terms Definitions For Aerospace Organizations Plexus International

Apqp Ppap のギャラリー

What Is The Apqp Advanced Product Quality Planning Process Qualityinspection Org

Apqp Advanced Product Quality Planning Quality One

Ppap Introduction To Automotive Ppap

Ppap Training Program Reliatrain

Ppap Process Flow Chart Example The Future

Automotive Apqp Ppap With Aiag Vda Fmea And Functional Safety

Ppap Apqp Core Tools For Automotive Bv

Advanced Product Quality Planning Apqp Ppap Software Omnex

Apqp Checklist

Advanced Product Quality Planning Softexpert Apqp Ppap

Q Tbn And9gcrmagvjc3tztktznvc Zg Vbyfzujrvaevbxk5q9mo Usqp Cau

Apqp Ppap Integrated Implementation With As9100 Youtube

Ppt Nordin Mimouni Supplier Quality Manager Rev 01 Nov 29th 18 Powerpoint Presentation Id

Provide The Best Apqp Ppap Process Document Matrix Package By Jkleisley

As9100 News Ppap In The Aerospace Sector What Is It As9145 Requirements For Advanced Product Quality Planning And Production Part Approval Process

Plaskar Plastic Injection Mold Production Apqp Ppap

Apqp Ppap

Consultations Apqp Ppap Usluga Tqmsoft

Apqp Training Ppap 4th Edition Apqp Ppap Training Series

Quiz Worksheet Pm Apqp Ppap Documentation Study Com

Ts Core Tools Ppap Spc Sqc Fmea Apqp Msa Control Plan Ts Jaipur Rajasthan Ncr

Www Sma De Fileadmin Content Global Partner Documents Supplier Quality Gsq 010 Supplier Apqp Ppap V2 Pdf

Rocket Trucentrix Automate The Ppap Process Within Apqp Rocket Software

Smart Qms Apqp Ppap Npi Module Blue Ocean Data Solutions

Ppap

Features Ppap Manager

E Apqp Implementation

Supplier Apqp Gated Review Elsmar Apqp Gated Apqp Gated Review Apqp Phases Pre Production Control Plan Resource List Job Award Ppap I Readiness Ppap Ii

Advanced Quality Planning Production Part Approval Process Apqp Ppap Integrated Implementation With As9100d On Vimeo

Smart Qms Apqp Ppap Npi Module Blue Ocean Data Solutions

Apqp Ppap Support Mcdae Global Inc

Core Tool Training Apqp Ppap Spc Msa More Posts Facebook

1 Apqp Ppap Advanced Product Quality Planning Quality Management System

7 2 3 Aerospace Apqp Manual 10may17 1

1 Apqp Ppap Advanced Product Quality Planning Quality Management System

Product Planning Ppap Production Process Se Apqp Ppap Softexpert Youtube

What S The Difference Between Apqp And Ppap

Apqp Ppap Fmea Spc Msa Training Services In New Area Faridabad Master Group

Ppap Apqp Core Tools Pour L Industrie Automobile Bv

Advanced Product Quality Planning Apqp Production Part Approval Process Ppap Design Business

What Is Apqp Iatf Store

Apqp Lean Manufacturing And Six Sigma Definitions

Advanced Product Quality Planning Apqp 5 Core Quality Tools Apqp And Ppap Youtube

Supporting Npi With As9145 Advanced Product Quality Planning

Core Tools Apqp Ppap Msa Spc Fmea Aiag Vda Quality Hub India

Se Apqp Ppap Softexpert Software

Urs Testing Inspection Certification Urs We Are Pleased To Announce Online Training For Automotive Sector Iatf Apqp Ppap Fmea And Cp Ursindia Iatf Iatftraining Iatf Automotivesector Apqp Ppap

Core Tools Apqp And Ppap

Apqp Ppap

五大质量工具详解及运用案例 Apqp Fmea Ppap Msa Spc 谭洪华 Amazon Com Books

Apqp En

Iatf Five Core Tools What Are They

Apqp Ppap Msa Training आईएसओ प रम ण करण क सल ट स In Chikhli Jros Auto Parts Id

Apqp Plato Ag Solutions By Software

Q Tbn And9gcqvytz1w2uzzbfqleyvuqqgsem9q4ic2mjfjl4vkzl2gn4gyrp0 Usqp Cau

Apqp Ppap

Virtual Collaborative Apqp Software Solution Integrated With Aiag Vda Fmea

Technical Review Ppap Apqp Chaudhary Fulbodh Ebook Amazon Com

Pdf Measurement Of Effectiveness Of New Products Implementation Process According To Apqp Ppap Requirements Proposition Of Indices Semantic Scholar

Advanced Product Quality Planning And Production Part Approval Process St Marys Nwirc

Ppap Training Qualitytrainingportal

Apqp Advanced Product Quality Planning Supplier Version Ppt Download

A P Q P P P A P Successful Ppap Through Structured Apqp Process Five Phases Of Apqp With Pdf Document

Ppap Production Part Approval Process Imds Ppap

What Is The Purpose Of A Ppap

Q Tbn And9gctxmrcp0zm0yioeqlejosjlfjszba86gkyfm3qptutvlchj2xrc Usqp Cau

Advanced Product Quality Planning Apqp Production Part Approval Process Ppap

Quality Core Tools Quality One

Core Tool Training Apqp Ppap Spc Msa More Home Facebook

Ppap Production Part Approval Process Automotive Quality Solutions

Apqp Ppap Training Course Training Institutes Master Quality Vision Faridabad Id

Apqp Advanced Product Quality Planning Quality One

What Is Ppap Qualitytrainingportal

Bright Direction Core Tool Training Apqp Ppap Spc Msa More Facebook

Will Apqp Ppap Add Real Value Midaero Consultancy

Aiag Apqp Ppap

Production Part Approval Process Ppap Ppap And Apqp Training Lean Six Sigma Informative Video Talk

Jumanji Group Limited Apqp Ppap Program

As9145 Aerospace Apqp And Ppap Workshop Quality Support Group

Automotive Qms Your Competition Is Ahead Of The Curve

Apqp Advanced Product Quality Planning Quality One

Apqp Ppap Doqs

Apqp Ppap Reikalavimai Quality Loupe

What Is The Apqp Advanced Product Quality Planning Process Qualityinspection Org

Apqp Ppap Questionnaire Technology Engineering Business

As9145 Apqp Ppap Requirements For The Aerospace Defense Industry

Workshop Apqp Ppap Mikrocentrum

Aqua Pro Product Realization Apqp Ppap Software By Omnex

Apqp Ppap Software Advanced Product Quality Planning

Apqp Ppap Manager Intelex

Q Tbn And9gcttjjepinxp7zyeauyx1jlpmf1wqlfn8qu6knsa1mu 22z Kzie Usqp Cau

Qa Session 1 Welcome To Apqp Manual And Workbook In Details Apqp4wind Apqp Ppap Process Flow Production Part Approval Process Ppap

Journals Sagepub Com Doi Pdf 10 1177

As9145 Apqp And Ppap For Aerospace Simpleque

Ppap Apqp Vanderhorst Brothers Inc

Pdf Apqp Ppap Software Overview Dfmea Process Flow Pfmea Control And More

As En Sjac 9145 16 Apqp Ppap Meeting Requirements

Fhi Nl App Uploads Sites 71 17 02 Neways Micro Electronics Micro Assembly For The Automotive Market How To Excecute Pdf

Apqp Advanced Product Quality Planning Quality One

Omnex Certification In Apqp Ppap

Apqp Ppap Evidence Workbook