Fracture Stress Engineering

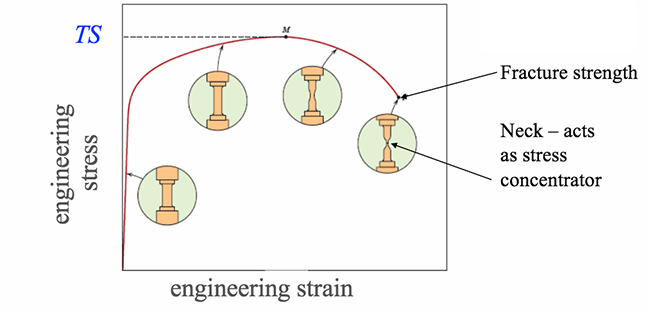

Fracture stress is only less than ultimate tensile strength in an engineering stressstrain diagram This is because the material will experience a maximum stress before it undergoes necking After.

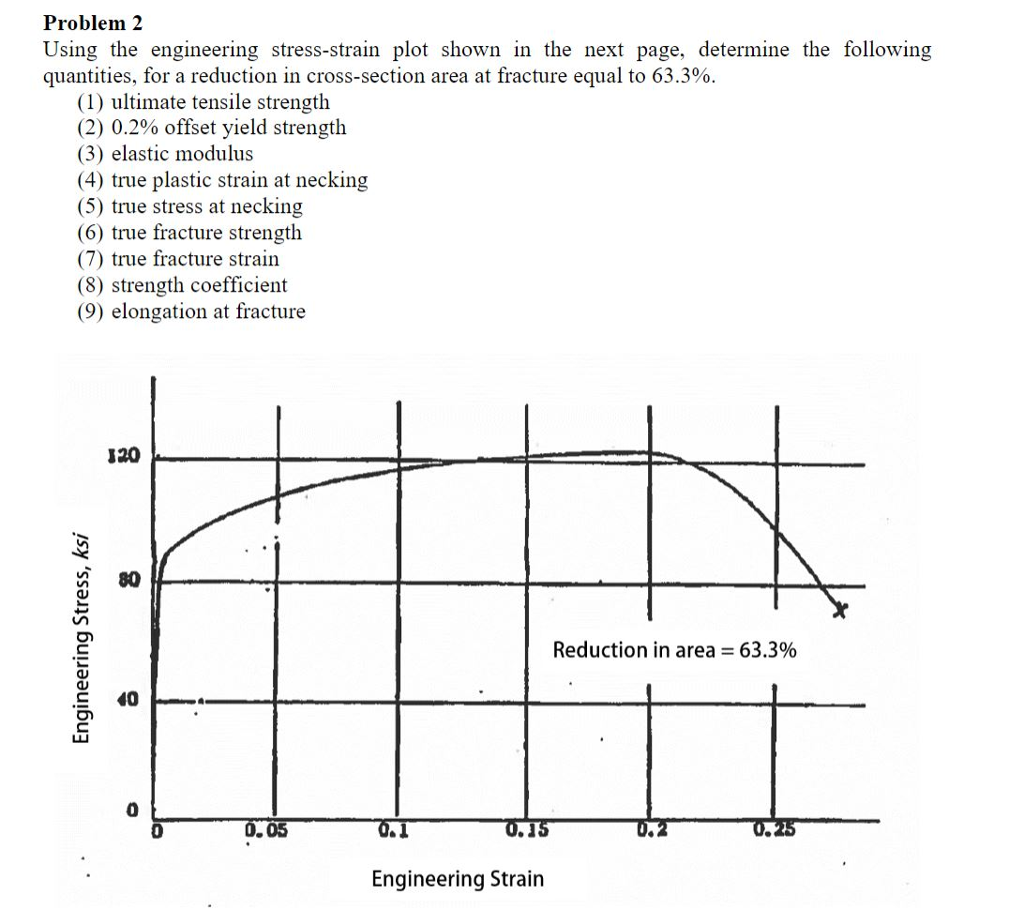

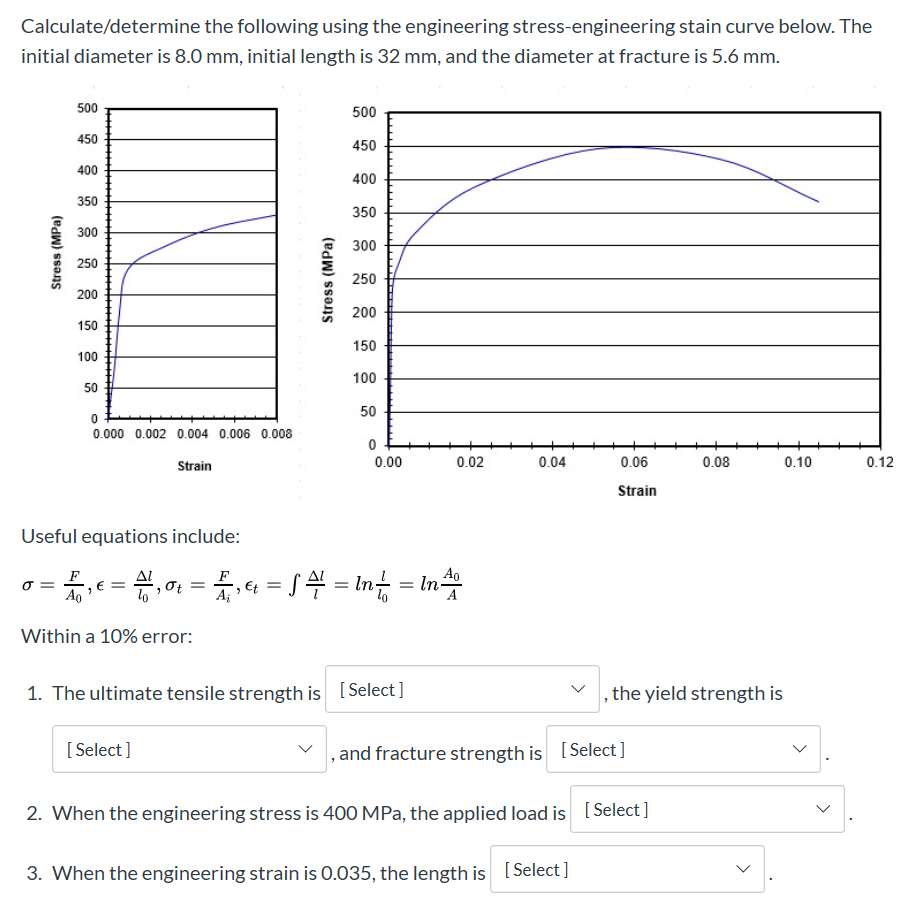

Fracture stress engineering. Engineering stress at fracture according to the table engineering stress at fracture According to the table the engineering stress at fraction σ = 140 Ksi (g) The true stress at necking True stress at necking σ = S UTS ( 1 e UTS ) 3 This is the last data point at which this expression for true stress is valid According to table σ = 180 Ksi ∗ ( 1 070 ) 192 Ksi (h) The modulus of resilience Area under the elastic portion of a stressstrain curve. Fracture strength is a measure of the force needed to break an object Key Terms strain The amount by which a material deforms under stress or force, given as a ratio of the deformation to the initial dimension of the material and typically symbolized by ε is termed the engineering strain The true strain is defined as the natural logarithm of the ratio of the final dimension to the initial dimension. Since the plunge of SS curve indicate that the material structure loss it's integrality to ensure stress transfer (fracture point), so you can just consider the stress at max point in the figure.

A stress fracture is a fatigueinduced bone fracture caused by repeated stress over time Instead of resulting from a single severe impact, stress fractures are the result of accumulated injury from repeated submaximal loading, such as running or jumping Because of this mechanism, stress fractures are common overuse injuries in athletes Stress fractures can be described as small cracks in the bone, or hairline fractures Stress fractures of the foot are sometimes called "march fractures" becau. FRACTURED MECHANICS is the study of flaws and cracks in materials It is an important engineering application because the presence of cracks can significantly decrease the structural strength and reliability of parts The traditional Strength of Material approach does not anticipate the presence of a crack or does so via concentration factors. • K is the stress concentration factor • The presence of cracks on the surface or inside the body may severely reduce the tensile stress that a material can withstand with fracture • Fracture stress depends on the crack radius and crack depth • Fracture stress is also a function of material constant, which need to be determined in.

σ m a x = lim ρ → 0 S ( 1 2 D ρ) ≈ 2 S lim ρ → 0 D ρ (12) Clearly the idea of stress concentration factor breaks down for a crack, since it cannot distinguish between various crack lengths and applied stress levels It is interesting, however, to examine a product, 1 2 σ m a x π ρ = 1 2 ( 2 S D ρ) π ρ = S π D. On the other hand, the true stress is the load devided by the true area, which continues to be smaller by the tensile load The true stress continues to increase to the point of fracture, while the engineering stress decreases to the point of fracture due to the increasing load and the constant crosssectional area The engineering strain is. In petroleum engineering, fracture mechanics theories have been used for more than 50 years Rock fracture mechanics is about understanding what will happen to the rocks in the subsurface when subjected to fracture stress Much of what is used in hydraulic fracturing theory and design was developed by other engineering disciplines many years.

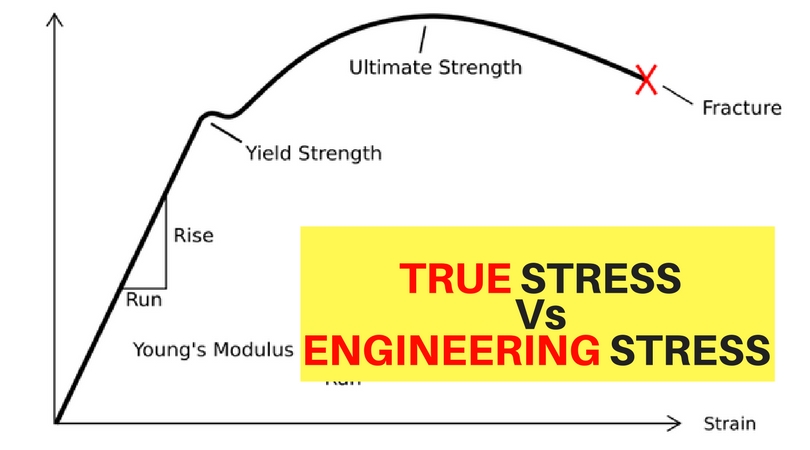

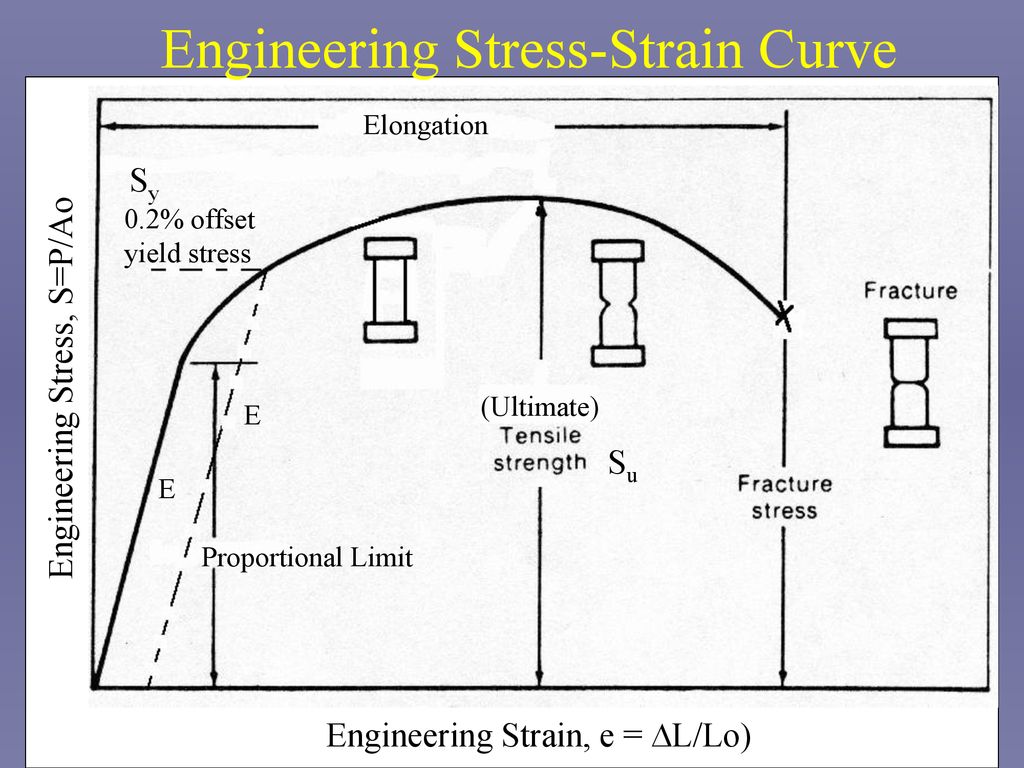

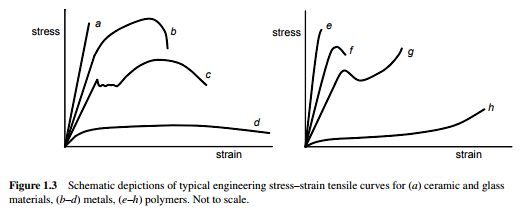

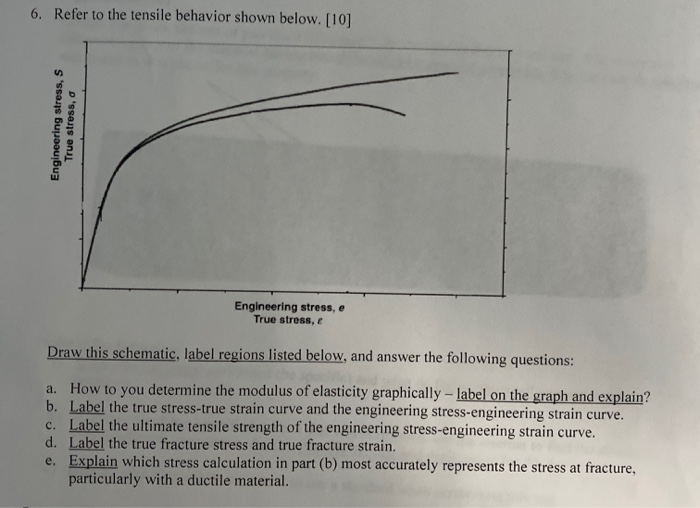

The fall in the engineering stress after the UTS is achieved, due to the presence of the neck, does not reflect the change in strength of the metal itself, which continues to work harden to fracture If the true stress , based on the actual crosssection (A) of the gauge length, is used, the stress–strain curve increases continuously to fracture, as indicated in Fig 25. Tensile strength and fracture toughness, important parameters of the rock for engineering applications are difficult to measure Thus this paper selected three kinds of granite samples (grain sizes = 101mm, 212mm and 3mm), used the combined experiments of physical and numerical simulation (RFPADIP version) to conduct threepointbending (3pb) tests with different notches and introduced. An engineering stressstrain curve is constructed from the load elongation measurements (Fig 1) Figure 1 The engineering stressstrain curve load required to deform the specimen falls off and the engineering stress likewise continues to decrease until fracture occurs Tensile Strength.

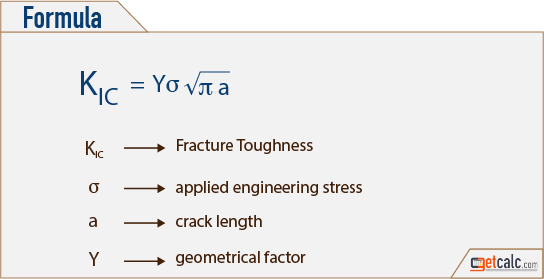

Fracture stress is only less than ultimate tensile strength in an engineering stressstrain diagram This is because the material will experience a maximum stress before it undergoes necking After. Engineering Stress Engineering Strain Shear Stress Elastic or Young's Modulus Calculator Shear Modulus Bolt Stress (σ ) Area Fracture Toughness Thermal Property Deformation Fracture Toughness applied engineering stress crack length geometrical factor Formula from Belt Velocity & Tension. Fracture, In engineering, rupture of a material too weak to sustain the forces on it A fracture of the workpiece during forming can result from flaws in the metal;.

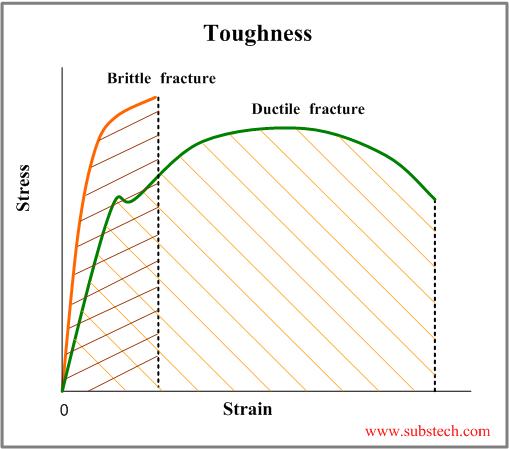

In the tensile test, the fracture point is the point of strain where the material physically separates At this point, the strain reaches its maximum value and the material actually fractures, even though the corresponding stress may be less than the ultimate strength at this point Ductile materials have a fracture strength lower than the ultimate tensile strength (UTS), whereas in brittle materials the fracture strength is equivalent to the UTS. If a displacement develops tangentially to the surface of displacement, it is called a shear crack, slip band, or dislocation Brittle fractu. A brittle fracture is the fracture of a metallic object or other material without appreciable prior plastic deformation It is a break in a brittle piece of metal that failed because stress exceeded cohesion The brittle fracture of normally ductile steels occurs primarily in large, continuous, boxlike structures such as Box beams;.

One of the most important and major concepts in the entire field of Materials Science and Engineering is fracture In its simplest form, fracture can be described as a one body being separated into pieces by forced stress. A standard uniaxial tensile test, which establishes the engineering stressstrain relationship, in general, provides the basic mechanical properties of steel required by a structural designer Modern numerical analysis techniques used for analysis of large strain problems such as failure analysis of steel structures and elements metal forming, metal cutting, and so forth, will require. Abstract This is a proposal to develop the theory of solid engineering material fracture Although fracture is one of the most fundamental concepts in engineered structures, causing much research.

One of the biggest concerns with brittle fracture is that it can occur at stresses well below the yield strength (stress corresponding to the transition from elastic to plastic behavior) of the material, provided certain conditions are present These conditions are a flaw such as a crack;. Fracture strength is a measure of the force needed to break an object Key Terms strain The amount by which a material deforms under stress or force, given as a ratio of the deformation to the initial dimension of the material and typically symbolized by ε is termed the engineering strain The true strain is defined as the natural logarithm. Fracture mechanics is a study of bodies containing such discontinuities or "defects" An applied stress can be thought of as energy input to a body This energy approach to fracture mechanics was proposed by Griffith using the first law of thermodynamic A body under an applied stress is capable of absorbing some energy through elastic deformation.

A fracture is the separation of an object or material into two or more pieces under the action of stress Engineers need to understand fracture mechanisms There are fractures (eg brittle fracture), which occur under specific conditions without warning and can cause major damage to materials. In a uniaxial tensile test, a steel specimen is stressed to the point of fracture at engineering stress of 500 MPa, at which point the final diameter of the specimen is 16 mm Given that the original diameter of the cylindrical specimen was 10 mm, what is the true fracture stress?. Stress Engineering Services has been providing custom engineering solutions to customers since 1972 Learn more about our capabilities and how we can help!.

Fatigue & Fracture of Engineering Materials & Structures (FFEMS) encompasses the broad topic of structural integrity which is founded on the mechanics of fatigue and fracture, and is concerned with the reliability and effectiveness of various materials and structural components of any scale or geometry The editors publish original contributions that will stimulate the intellectual innovation. These often consist of nonmetallic inclusions such as oxides or sulfides trapped in the metal during refining. EFM covers a broad range of topics in fracture mechanics to be of interest and use to both researchers and practitioners Contributions are welcome which address the fracture behavior of conventional engineering material systems as well as newly emerging material systems.

The stress intensity factor (SIF) plays the most pivotal role in the application of linear elastic fracture mechanics (LEFM) principles to practice It is useful in the assessment of safety or reliability of a machine or structural component with a crack. The stress intensity factor (SIF) plays the most pivotal role in the application of linear elastic fracture mechanics (LEFM) principles to practice It is useful in the assessment of safety or reliability of a machine or structural component with a crack. Fracture Mechanics • It was shown that the theoretical cohesive stress is much greater than the observed fracture stress for metals • This lead to the idea of defects or cracks which locally raise the stress to the level of the theoretical cohesive stress • The first successful theoretical approach for brittle fracture was introduced by Griffith.

And a temperature low enough to promote brittle fracture. The stress state of the formation and the fracture criteria is shown in the figure below Looking at a rock element, the total vertical stress is simply the overburden stress, ie Remember , so it does include the pore pressure term. True stress is related to engineering stress Assuming material volume remains constant A A A P A A A P A P o o o o Flexural Strength the stress at fracture under the bending tests It’s also called Modulus of rupture, fracture strength, or the bend strength 3point Bending tests 3 2 2 3 R F L bd F L f fs f fs.

The true stress continues to increase to the point of fracture, while the engineering stress decreases to the point of fracture due to the increasing load and the constant crosssectional area The engineering strain is ε=l−l0l0{\displaystyle \varepsilon ={\frac {ll_{0}}{l_{0}}}}. FRACTURED MECHANICS is the study of flaws and cracks in materials It is an important engineering application because the presence of cracks can significantly decrease the structural strength and reliability of parts The traditional Strength of Material approach does not anticipate the presence of a crack or does so via concentration factors. Fracture is the separation of an object or material into two or more pieces under the action of stress The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid If a displacement develops perpendicular to the surface of displacement, it is called a normal tensile crack or simply a crack;.

Fracture stress is stress at breaking point of a material or the stress at which crack forms in the material If crack formation is due to pure tension (eg axially loaded bar) then fracture stress is equal to ultimate tensile strength Rupture of an axially loaded bar under pure tensile stress. A stress of sufficient intensity to develop a small deformation at the crack tip;. Stress fractures are tiny cracks in a bone They're caused by repetitive force, often from overuse — such as repeatedly jumping up and down or running long distances Stress fractures can also develop from normal use of a bone that's weakened by a condition such as osteoporosis.

If the true stress, based on the actual crosssectional area of the specimen, is used, it is found that the stressstrain curve increases continuously up to fracture If the strain measurement is also based on instantaneous measurements, the curve, which is obtained, is known as a truestresstruestrain curve. Topics Covered Basic fracture mechanics, atomic view of fracture, Griffith energy criterion, energy release rate R and driving force curves, stress analysis, crack tip plasticity, mixed mode fracture, crack tip opening displacement, J Integral, JCTOD relationships, crack growth resistance curves, J controlled fracture,dynamic fracture, rapid crack propagation/arrest, creep crack growth. At Stress Engineering Services, we use a comprehensive approach to identifying susceptible equipment, executing the brittle fracture analysis, and performing the process hazards analyses to evaluate and develop mitigation for atrisk vessels and piping.

A fracture is the separation of an object or material into two or more pieces under the action of stress Engineers need to understand fracture mechanisms There are fractures (eg brittle fracture), which occur under specific conditions without warning and can cause major damage to materials. True Fracture Strain The true fracture strain f is the true strain based on the original area A0 and the area after fracture Af (2) This parameter represents the maximum true strain that the material can withstand before fracture and is analogous to the total strain to fracture of the engineering stressstrain curve Since Eq. True Fracture Stress The true fracture stress is the load at fracture divided by the crosssectional area at fracture This stress should be corrected for the, triaxial state of stress existing in the tensile specimen at fracture Since the data required for this correction are often not available, truefracturestress values are frequently in.

Methods of Protection against Fracture i By surface treatment eg, etching and sizing etc Etching of glass in hydrofluoric acid removes the surface cracks and thus improves the strength of glass ii Introduction of compressive stress on the surface of a material makes the surface cracks ineffective. The decrease in the engineering stress is an illusion created because the engineering stress doesn’t consider the decreasing crosssectional area of the sample Let’s start by mathematically defining the true and engineering stressstrain curves, talk about why you might want to use one versus the other, and then dive into the math and show. The stressconcentration confines the process of slip on these slipbands, until finally the crystal separates by shear in two parts along a slip band, ie, separation occurs by sliding off on a slip plane Such a fracture is called shearfracture as extensive slip occurs on active slip plane before separation, and is promoted by shear stresses.

Stress Analysis An accurate stress analysis is an integral part of mechanical design Fatigue is very sensitive to stress, and ensuring the accuracy of load and stress estimates is an important step in fatigue engineering Hill Engineering staff perform stress analysis on a routine basis, often refining design analysis developed by our customer. Fracture mechanics is a methodology that is used to predict and diagnose failure of a part with an existing crack or flaw The presence of a crack in a part magnifies the stress in the vicinity of the crack and may result in failure prior to that predicted using traditional strengthofmaterials methods. A stress fracture is a very small crack in the bone This can happen from repetitive trauma and is commonly seen in athletes – particularly longdistance runners Stress injuries can be found in the shin bone, foot, heel, hip and lower back Treatment for stress fractures usually involves rest while the bone heals and changing your activity level to prevent another injury.

When deforming a sample, engineering stress simplifies by neglecting crosssectional change True stress correctly accounts for the changing crosssectional area The most obvious thing you may notice is that the true stressstrain curve never decreases That is because the material never gets weaker!.

Fracture Toughness Calculator

Scientific Net Publisher In Materials Science Engineering Stress Strain Curve Credit Metallurgical Engineering Facebook

Engarc L True Stress True Strain Engineering Stress And Engineerin Strain

Fracture Stress Engineering のギャラリー

Fracture Mechanics Of Porous Materials Imechanica

The Stress Strain Curve Intro To Structural Engineering

True Stress True Strain Models For Structural Steel Elements

Columbia University Civil Engineering And Engineering Mechanics Department Engineering Explanations For Part Two Of Our Stress Strain Curve Series We Will Talk About Three Points On The Stress Strain Curve The Yielding Point

Strength Of Materials The Engineer S Reference

Materials Testing Glossary Admet

What Is The Difference Between The True Stress And The Engineering Stress Quora

Converting Engineering Stress Strain To True Stress Strain In Abaqus

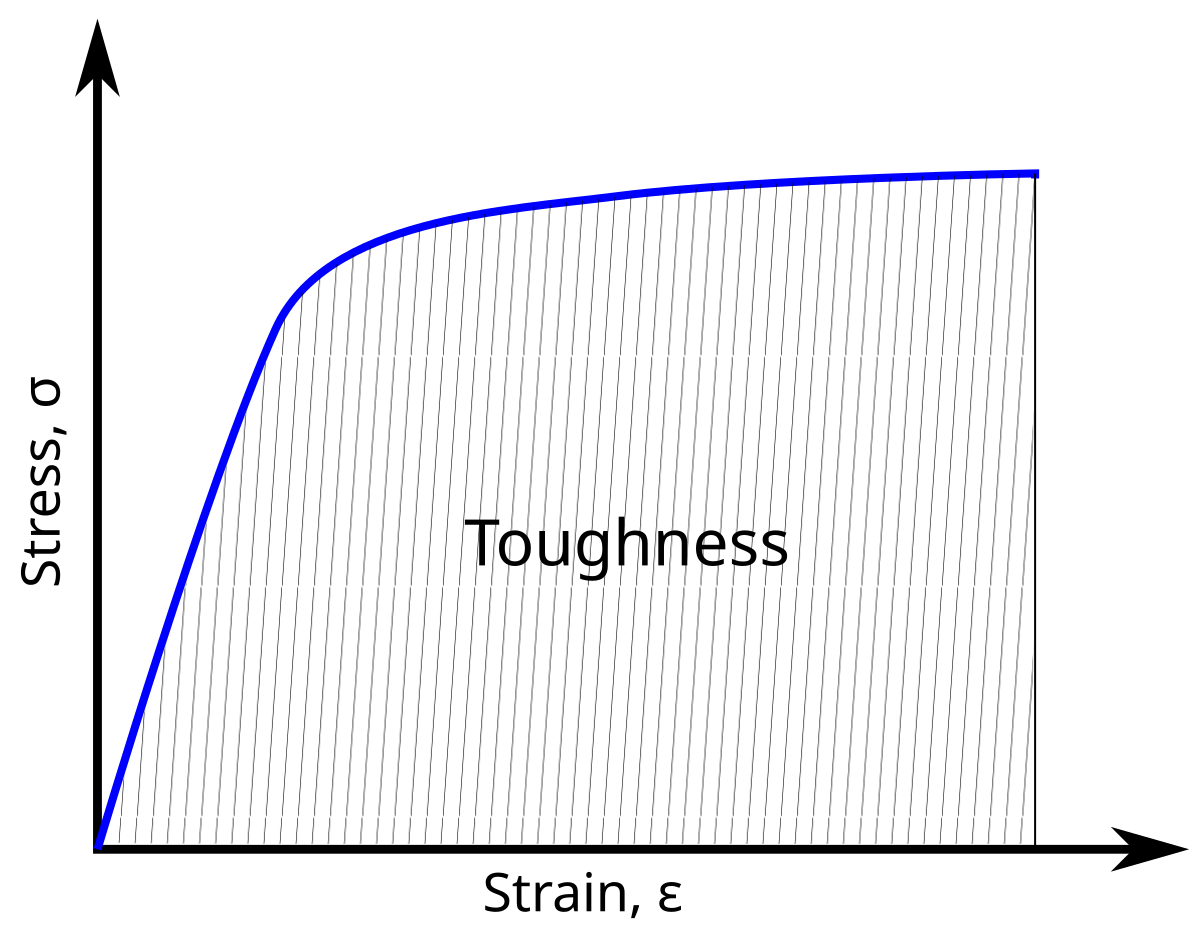

Toughness Wikipedia

Correlation Between Engineering Stress Strain And True Stress Strain Curve

Identification Of Ductile Fracture Parameter With Stress Correction Method Using Notched Round Bar Tensile Test Topic Of Research Paper In Materials Engineering Download Scholarly Article Pdf And Read For Free On Cyberleninka

What Is The Von Mises Stress And The Yield Criterion

Toughness

Steps To Analyzing A Material S Properties From Its Stress Strain Curve Stress Engineering Websites Study Materials

Fracture Point Fracture Strength Stress Strain Curve

Engarc L Stress Strain Diagram

Fracture Point Fracture Strength Stress Strain Curve

Plastic Deformation Matse 81 Materials In Today S World

Solved Problem 2 Using The Engineering Stress Strain Plot Chegg Com

Stress Versus Strain

Which Point In The Engineering Uniaxial Tensile S E Curve Indicates Damage Initiation The Ultimate Strength Point Or The Fracture Point

Materials Testing Glossary Admet

Local Tensile Stress As A Fracture Criterion For Brittle Crack Propagation In Steels Advances In Engineering

Engineering Stress Strain Curve Total Materia Article

Why Is It Not Possible To Obtain The True Fracture Stress Of A Metal From The Engineering Stress Strain Curve Quora

Stress Versus Strain

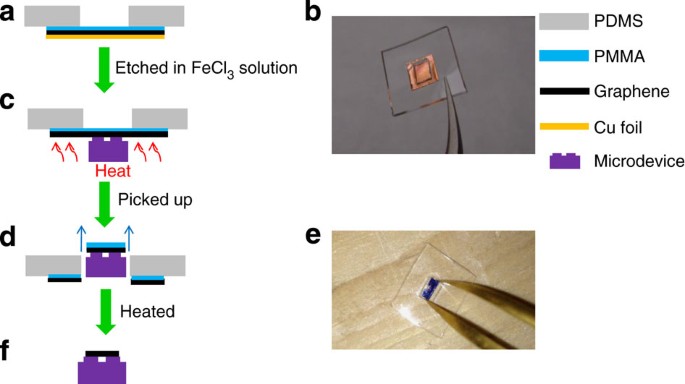

Fracture Toughness Of Graphene Nature Communications

Q Tbn And9gcrbuohd10sff9elvul6qav5o9uq6abfdahhewm3v4mu0zl3 7mh Usqp Cau

Ppt The Various Engineering And True Stress Strain Properties Obtainable From A Tension Test Are Summarized By The Categorized Listing Of Table 1 1 Powerpoint Presentation Free To Download Id 3aea75 Njq5o

Auto Refrigeration Brittle Fracture Stress Engineering Services Inc

Q Tbn And9gct8qzxo T8sviqsopp Bisx8t3mddgaelea S3nqszea0y7glhj Usqp Cau

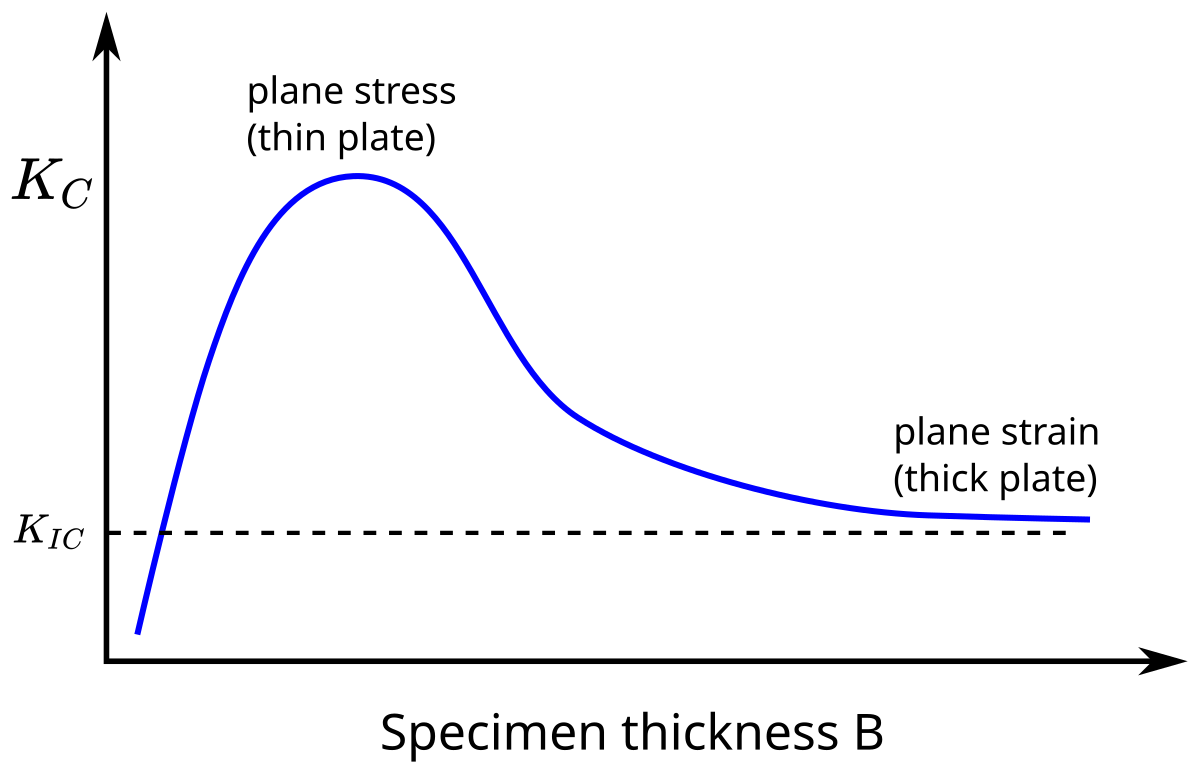

Fracture Toughness Wikipedia

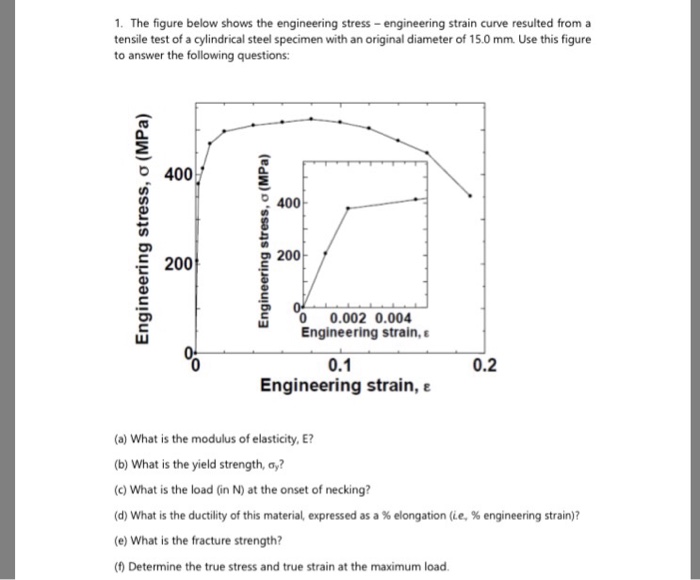

Solved 1 The Figure Below Shows The Engineering Stress Chegg Com

Brittle Fracture 15 Brittleness Fracture

Mechanical Properties Of Materials Mechanicalc

Tailoring Fracture Strength Of Graphene

Q Tbn And9gctk9iq8odyr8oad6ztec3f7a2cfwevlxhbui8zaefsdyzdh0s1n Usqp Cau

Strength Vs Hardness Vs Toughness Engineering Stack Exchange

Mechanical Properties Of Materials Mechanicalc

Ocw Tudelft Nl Wp Content Uploads Materiaalkunde 1 Slides Chapter8 Pdf

Investigation On True Stress Strain Curves Of Flat And Corner Regions Of Cold Formed Section Using 3d Digital Image Correlation Method

Stress Strain Curve Wikipedia

Seminar Assignments Assignment 2 Solutions Studocu

Http Academic Uprm Edu Pcaceres Courses Mateng3045 Eme8 2 Pdf

Why Is It Not Possible To Obtain Fracture Stress Of A Material From A Nominal Stress Strain Curve Quora

Cee 3710 Strength Versus Stiffness

True Stress Vs Engineering Stress Explained

Typical Engineering Stress Versus Strain Curves At Different Fracture Download Scientific Diagram

.jpg)

Engineering Applications Of Micro Cantilever Fracture Testing

Stress Strain And The Stress Strain Curve Materials Science Engineering

The Curve Of Engineering Stress Engineering Strain And The Position Of Download Scientific Diagram

Elasticity Stress Strain And Fracture Boundless Physics

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

Factor Of Safety

Fracture Toughness And Fatigue Crack Growth Behavior Of Rail Track Material Scientific Net

Analytical And Experimental Study Of Stress Sensitivity Effect On Matrix Fracture Transfer In Fractured Tight Reservoir Journal Of Petroleum Science And Engineering X Mol

2

Correlation Between Engineering Stress Strain And True Stress Strain Curve

Factor Of Safety

Mechanical Properties Of Metals Ppt Download

Fracture Mechanics

Stiffness And Deflection Mechanical Properties Of Materials

Yield Strength Strength Mechanics Of Materials Engineers Edge

Fracture Toughness Wikipedia

Loading Rates And Tensile Properties Fracture Toughness Twi

True Stress Strain Curve True Stress Strain Curve Vs Engineering True Stress Strain Curve Hindi Youtube

Stress Strain Curves Of Metallic Materials And Post Necking Strain Hardening Characterization A Review Tu Fatigue Amp Fracture Of Engineering Materials Amp Structures Wiley Online Library

Stress Strain Curve An Overview Sciencedirect Topics

Predicting Fracture In Civil Engineering Steel Structures State Of The Art Journal Of Structural Engineering Vol 143 No 3

Physical Chemical Properties

Fracture Toughness Substech

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

Www Osti Gov Pages Servlets Purl

Solution Manual For Manufacturing Processes For Engineering Materials 6th Edition By Kalpakjian By A Issuu

Fracture Toughness Measurement Types And Typical Values Matmatch

Converting Engineering Stress Strain To True Stress Strain In Abaqus

Chapter 6 Mechanical Properties Ppt Video Online Download

Fracture Mechanics A Tour Of Basic Principles Chapter 8 Geologic Fracture Mechanics

Stress Strain Curve An Overview Sciencedirect Topics

Solved Sketch Figure 1 3 Curve B A Ductile Metal Label It With The 1 Answer Transtutors

Fracture Mechanics With Residual Stress Product Brief Esrd Engineering Software Research And Development Inc

Mechanical Properties And Testing Of Metallic Materials Fatemi Major Reference Works Wiley Online Library

Http Academic Uprm Edu Pcaceres Courses Mateng3045 Eme8 2 Pdf

1 A Stages Of Tensile Test B True And Engineering Stress Strain Curve Download Scientific Diagram

Fracture Toughness Measurement Types And Typical Values Matmatch

Solved Calculate Determine The Following Using The Engine Chegg Com

Www Igsoc Org Journal 22 86 Igs Journal Vol22 Issue086 Pg135 143 Pdf

Materialfracture Background Material Fracture Stress Versus Strain Wiketomica

Stress Strain Curve Wikipedia

Fracture Mechanics Concepts Micro Macro Cracks Tip Blunting Toughness Ductility Yield Strength Youtube

Stress Strain And The Stress Strain Curve Materials Science Engineering

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

The Engineering Stress Engineering Strain Curve Of Carbon Structural Download Scientific Diagram

The Effect Of Residual Stresses And Strain Reversal On The Fracture Toughness Of Tial Alloys Materials Science And Engineering A X Mol

Stress Strain And The Stress Strain Curve Materials Science Engineering

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

Elastic Fracture Toughness For Ductile Metal Pipes With Circumferential Surface Cracks Scientific Net

Solved 6 Refer To The Tensile Behavior Shown Below 10 Chegg Com

Materials Engineering Science Processing And Design 2nd Edition

Q Tbn And9gcthfra1m3i0hx2z0gonsy0l Ct1isa3heprf6cjvtouheotxbrl Usqp Cau

Web Adanabtu Edu Tr Files Iyilmaz Duyuru Dosya Me 7 E2 80 93 chapter 3 P3 Pdf