Manufacturing Excellence Model

Dedicated to the journey of continuous improvement and enterprise excellence Join us at AME Atlanta 21 Join us virtually or in Atlanta for the 21 AME International Conference, Oct 11, 21.

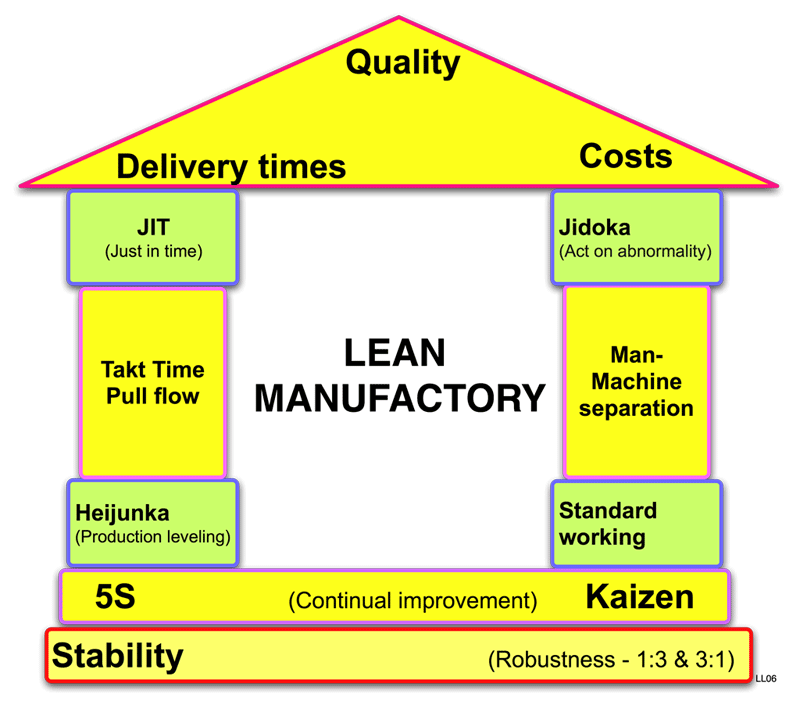

Manufacturing excellence model. This is part of the series of blog posts we are writing called “Measuring for Excellence“, in which we’ll be exploring the strategies and best practices some of the most successful companies employ to build a culture of manufacturing excellence in their organization. At Manufacturing Excellence we’ve spent the last years helping businesses succeed with longterm change and sustainable improvement In that time, we’ve continually developed our approach to make it as effective as possible in ensuring positive change for the companies we work with. This approach has been developed from ‘lean manufacturing’ / ‘just in time’ philosophies The model is equally applicable to large or small organisations in both high and low volume manufacturing environment Manufacturing excellence is based on a set of widely established suite of tools and techniques which together make up a model for.

Manufacturing Excellence program aims at holistic development of people in Manufacturing setups by equipping them with latest technologies / knowhow and other skills set required for their overall grooming as technical and general management experts It enhances productivity & competitiveness through development of people. What follows are the ten core principles of Operational Excellence, as identified by the Shingo Institute in its Shingo Model Respect Every Individual Every person in the organization must have respect for other members of the organization, for management, for the customers, for suppliers and business partners, for the community that it. How to Build More Impactful Centers of Excellence The critical issue when it comes to COEs isn’t whether the work they’re doing is important to the business It is how to ensure that their effort isn’t wasted This article provides two recommendations for how to best leverage the Center of Excellence model in support of business results.

Manufacturing ERP eresource EXCEL eresource ERP is designed for manufacturing excellence With visibility throughout the operation and embedded support for a wide variety of manufacturing processes including maketostock, maketoorder, configuretoorder, engineertoorder , justintime (JIT) manufacturing and materials control, and. Manufacturing Excellence Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free A Review of two books on the subject of attaining Manufacturing Excellence. This prize is unofficially referred to as the “Nobel Prize for Manufacturing” having achieved premier status over the years What The Shingo Model is and is not There are ten guiding principles to the Shingo Model governing the creation of operational excellence while organizing them into four dimensions.

The WCM targets excellence in manufacturing as a mean of delighting the customers, employees and other stakeholders on a sustainable basis I want to share lot of information about this model and its methodology I would like to highlight its uniquness and its superirity over other model of Excellence But First, I am attaching the components. Frost & Sullivan’s Global Manufacturing Excellence Model objectively assess a facility on 12 factors that define its being called flexible and lean These capture excellence on cost, quality, delivery, and innovation The subscores are computed based on the facility’s success on 255 “Points of Achievement” (POA) The assessment is. 5 Factors for Achieving Manufacturing Excellence in Good Times or Bad Because manufacturing capacity represents a massive investment that is difficult to relocate or sell off, flexibility and the ability to act quickly to market changes are difficult to cultivate That makes them enormously important for a competitive advantage.

Read More Lean Manufacturing Resources, Guides #3 Shine Shine is most likely the most literal of the pillars for Excellence from the Lean 5S Guide it literally means to remove all the dirt and grime and to keep the workplace clean on daily basis You want to get it clean and keep it clean When you implement this step, two things will happen. The Yagachi ManufacturingExcellence Model The Yagachi approach to Excellence is built on the concept of Lean and a spirited adherence to Certified Systems The tools and systems are deployed and practiced visually across the factories, enabling ease of use, control, and monitoring for every employee. Book Description Following in the tradition of its bestselling predecessor, The 12 Principles of Manufacturing Excellence A Lean Leader's Guide to Achieving and Sustaining Excellence, Second Edition outlines a comprehensive, proven process for delivering worldclass performance while also cultivating the right culture through leadership, mentoring, and hourly associate involvement.

Manufacturing excellence The only way Achieving 'The Vision' of $400 billion by 30 is not going to be easy and is improbable with businessasusual approachTo attain such growth target. Participating companies should be provided with or obtain a copy of EFQM Excellence Model ISBN to be used in conjunction with this document SC21 Performance, Development & Quality SC21 Man Ex overview December 13 2 LIST OF CONTENTS Section Page 1 SC21 Manufacturing Excellence overview 3 2 Diagnostic 4. The WCM targets excellence in manufacturing as a mean of delighting the customers, employees and other stakeholders on a sustainable basis I want to share lot of information about this model and its methodology I would like to highlight its uniquness and its superirity over other model of Excellence But First, I am attaching the components.

Manufacturing tries to minimise this waste and benefit consumers in the form of lower prices Toyota, the world’s largest car manufacturer, was the first company to successfully adopt this model The company’s steady growth from a small company to the world’s largest automaker has made the Japanese carmaker an. 5 Factors for Achieving Manufacturing Excellence in Good Times or Bad Because manufacturing capacity represents a massive investment that is difficult to relocate or sell off, flexibility and the ability to act quickly to market changes are difficult to cultivate That makes them enormously important for a competitive advantage. MANUFACTURING EXCELLENCE Dr Krishnan Umachandran 18 ROLL OUT Components Components This paper extends the study on profitable partial resale model in two directions with both.

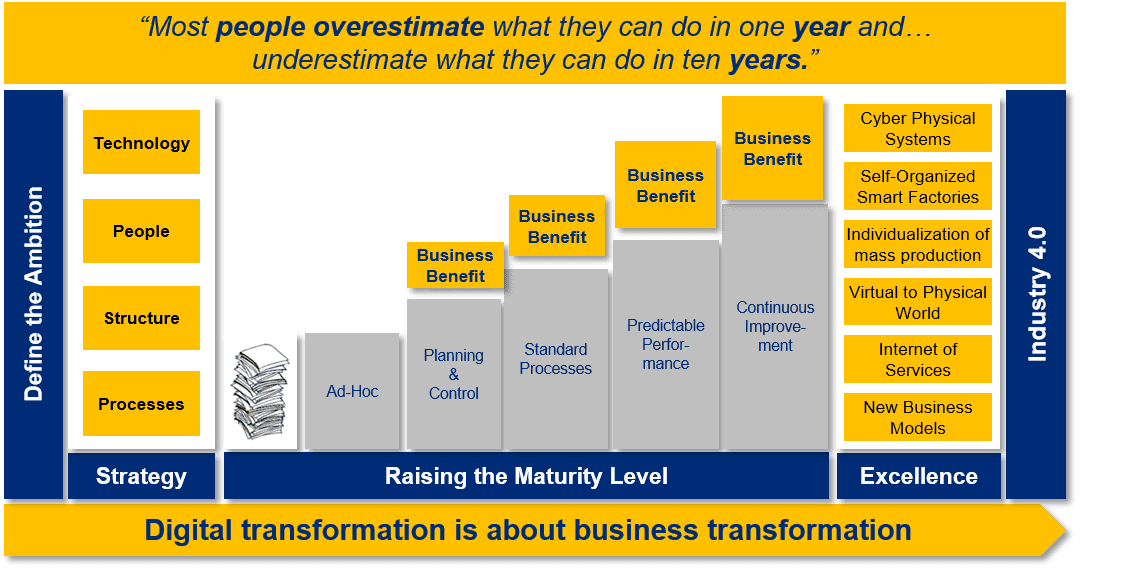

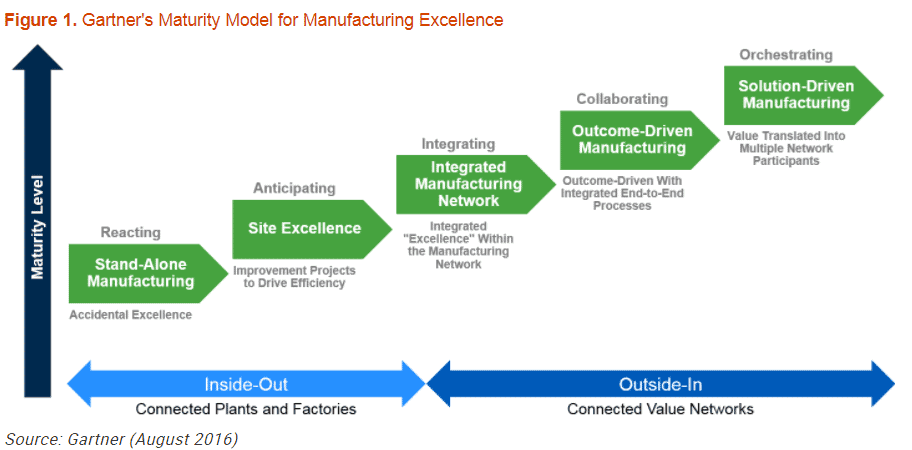

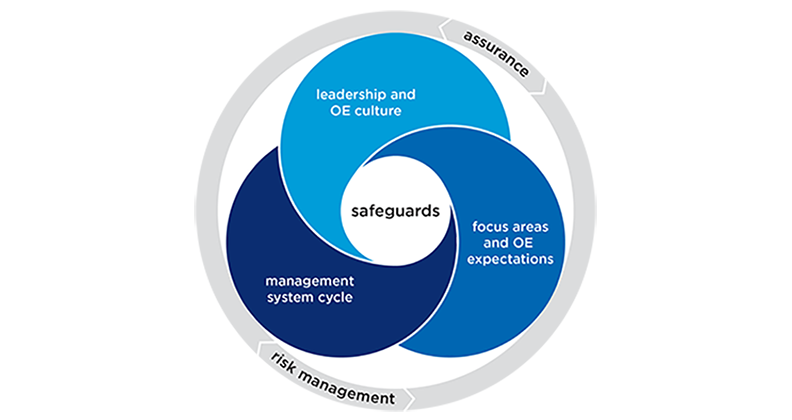

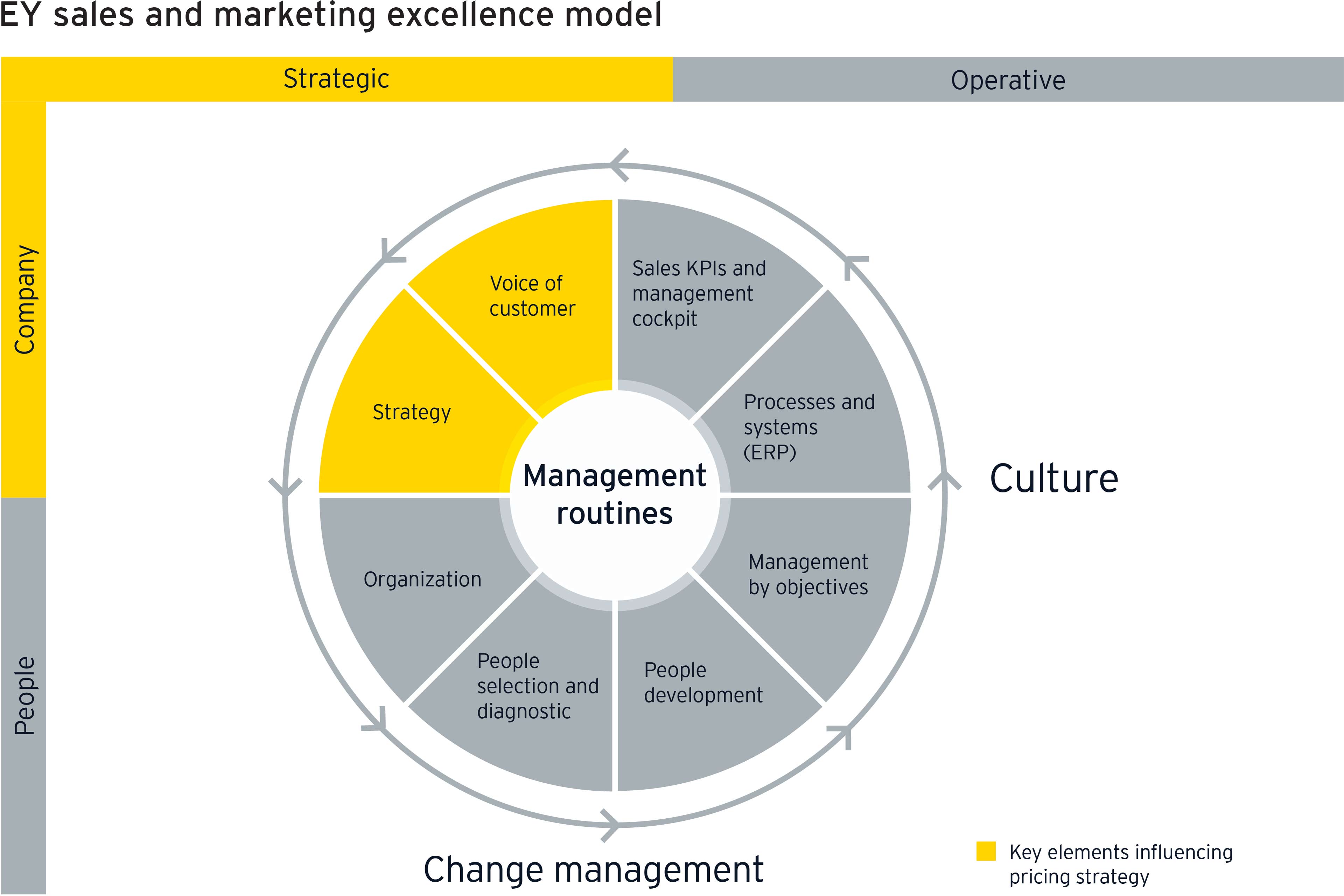

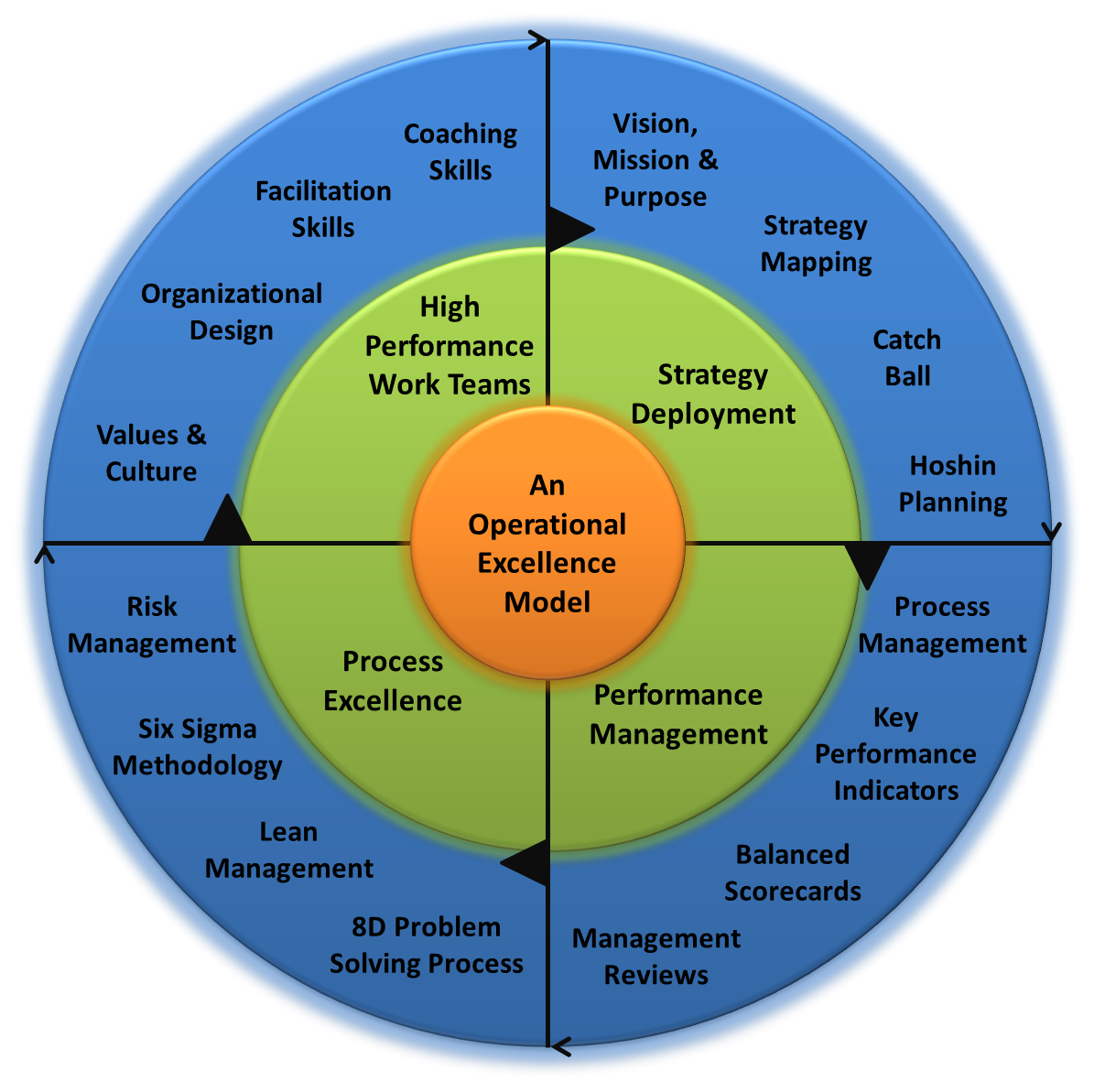

5 Excellence Establishing a Model of We’ve developed a model that can be implemented into new or existing operational excellence programs 6 6 Excellence Establishing a Model of Risk Management and Compliance Goal Operate safely and in compliance with all business and regulatory requirements 7. The very first step on the Operational Excellence model is the strategy pillar, as by definition it refers to the execution of everything that comes after The main criteria of our model focuses on the types of strategy characteristics that facilitate not only its implementation but also the willingness of the people to adhere to it. The Gartner Maturity Model for Manufacturing Excellence is a tool for gauging the health and direction of manufacturing operations Manufacturing and supply chain leaders can use it to create the manufacturing vision, describe the business case for change and track improvements.

The Operational Excellence PPT presentations overview the Plant Wellness Way to Operational Excellence model Getting operational excellence success is difficult until you have a successful operational excellence model to follow The image below shows the course content in the three days of the Operational Excellence PPT presentations. "Excellence" Makes Its DebutSiemens has developed a new service package for manufacturers and operators of machine tools Sinumerik Manufacturing Excellence Gigafren • Manitoba Consortium for Manufacturing Excellence (MCME) A Winnipegbased consortium of 11 manufacturers dedicated to working toward World Class Performance. Get regular updates about Five S, Lean Operations Management, Lean Operations, Lean Management, Lean manufacturing Kaizen Institute India's Blog is a collection of expert insights and industry news to help accelerate your company's growth.

Using a wholesystems view of Program and Functional work, the Performance Excellence Model (PEM) helps measure the key value propositions that make a difference for program and enterprise success This presentation introduces the Performance Excellence Model (PEM), but will mostly. A Roadmap for Global Manufacturing Excellence 5 PILLAR 1 A GLOBAL OPERATIONS SOLUTION DELMIA Apriso for manufacturing operations management offers the technology foundation that enables manufacturers to easily develop, model, test, and deploy standardized business processes to every site. A Manufacturing Excellence Programme with a focus on driving worldclass quality and production practices, as well as building people skills and a robust culture is being driven across the Blue Star factories The Company’s focus on manufacturing excellence is born out of its core philosophy of ‘customer first’ This philosophy is visible.

White Paper A Manufacturing Marshall Plan To help manufacturers successfully navigate the postpandemic economy, AME is proud to share insights on how today’s companies can prevent postpandemic supply chain disruptions, advance their manufacturing productivity and reskill workforces. The Operational Excellence PPT presentations overview the Plant Wellness Way to Operational Excellence model Getting operational excellence success is difficult until you have a successful operational excellence model to follow The image below shows the course content in the three days of the Operational Excellence PPT presentations. Operational Excellence is a mindset, not a methodology It is the relentless pursuit of finding ways to improve performance andprofitability It seeks to lower risk, lower operating costs, and to increase revenue by ensuring that each and every employee can see the flow of value to the customer and fix that flow before it breaks.

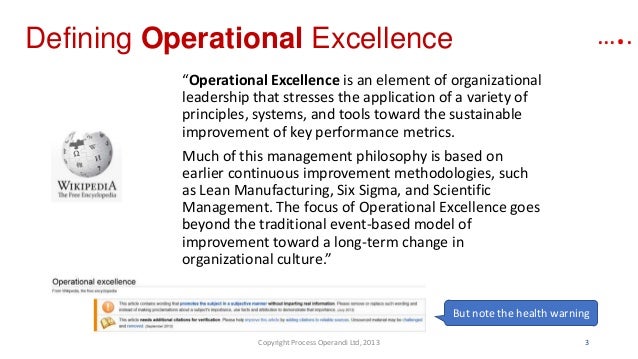

Manufacturing Excellence Much of this philosophy is based on earlier continuous improvement methodologies, such as Lean Manufacturing, Six Sigma, and Scientific Management The focus of Operational Excellence goes beyond the traditional eventbased model of improvement toward a longterm change in organizational culture. Keywords quality, QMS, excellence, EFQM, model 1 Quality Management System Application The Faculty of Mechanical Engineering joined the project focused on applying the Quality Management System at the VSB Technical University of Ostrava at the end of the year 04 in the concurrence with the pilot application of QMS at the Faculty of. Operational Excellence 10 Core Principles Every year, the Shingo Institute of the Jon M Huntsman School of Business gives out an award for operational excellence called the Shingo Prize This prize is based on company culture, company results, and how well every employee demonstrates the Guiding Principles of the Shingo Model.

Participating companies should be provided with or obtain a copy of EFQM Excellence Model ISBN to be used in conjunction with this document SC21 Performance, Development & Quality SC21 Man Ex overview December 13 2 LIST OF CONTENTS Section Page 1 SC21 Manufacturing Excellence overview 3 2 Diagnostic 4. Lean is a common approach to operational excellence in manufacturing, and flow is an important Lean concept Socalled onepiece flow concerns moving each unit through production individually, rather than in batches Employing this method increases efficiency by connecting processes and, thereby, enhancing flow in the value stream. MANUFACTURING EXCELLENCE Dr Krishnan Umachandran 18 ROLL OUT Components Components This paper extends the study on profitable partial resale model in two directions with both.

A Roadmap for Global Manufacturing Excellence 5 PILLAR 1 A GLOBAL OPERATIONS SOLUTION DELMIA Apriso for manufacturing operations management offers the technology foundation that enables manufacturers to easily develop, model, test, and deploy standardized business processes to every site. At Manufacturing Excellence we’ve spent the last years helping businesses succeed with longterm change and sustainable improvement In that time, we’ve continually developed our approach to make it as effective as possible in ensuring positive change for the companies we work with. Book Description Following in the tradition of its bestselling predecessor, The 12 Principles of Manufacturing Excellence A Lean Leader's Guide to Achieving and Sustaining Excellence, Second Edition outlines a comprehensive, proven process for delivering worldclass performance while also cultivating the right culture through leadership, mentoring, and hourly associate involvement.

© 21 · Foundation for Manufacturing Excellence · All rights reserved website design and development by Imagemakers. This is part of the series of blog posts we are writing called “Measuring for Excellence“, in which we’ll be exploring the strategies and best practices some of the most successful companies employ to build a culture of manufacturing excellence in their organization. His book, The 12 Principles of Manufacturing Excellence—A Lean Leader's Guide to Achieving and Sustaining Excellence, 2nd Edition, was released September, 15 by CRC Press, Taylor & Francis Group, as a Productivity Press book The original book, a best seller, was published in October, 11.

Toyota Operational Excellence Management Model Khalil, R Abstract— The Japanese Car Industry is growing to take market segment in all regions of the world The major manufacturers operate on all continents with production facilities spread across the world. The future of operational excellence for manufacturing is not in words like productivity, efficiency, and standardization It will be in concepts like growth, innovation, and customization The world is more connected and fastpaced than it has ever been, and the manufacturing industry needs to keep pace. Manufacturing tries to minimise this waste and benefit consumers in the form of lower prices Toyota, the world’s largest car manufacturer, was the first company to successfully adopt this model The company’s steady growth from a small company to the world’s largest automaker has made the Japanese carmaker an.

We have been pondering for some time how we can articulate a model that reflects the issues we repeatedly see, while creating a framework on which an improvement strategy can stand After many years of discussions, contemplations, reflection, enquiry (and more than one bottle of red!), we realised that manufacturing excellence can be understood. Manufacturing excellence model On 25th December By Home December 25 manufacturing excellence model. In their simplest forms, these methodologies of manufacturing excellence are all about eliminating waste (lean) and reducing variation in the production process (reliability) Any approach to manufacturing excellence owes a huge debt to Dr Shigeo Shingo The idea of continuous change is a key concept embodied in Kaizen, or “change for better.

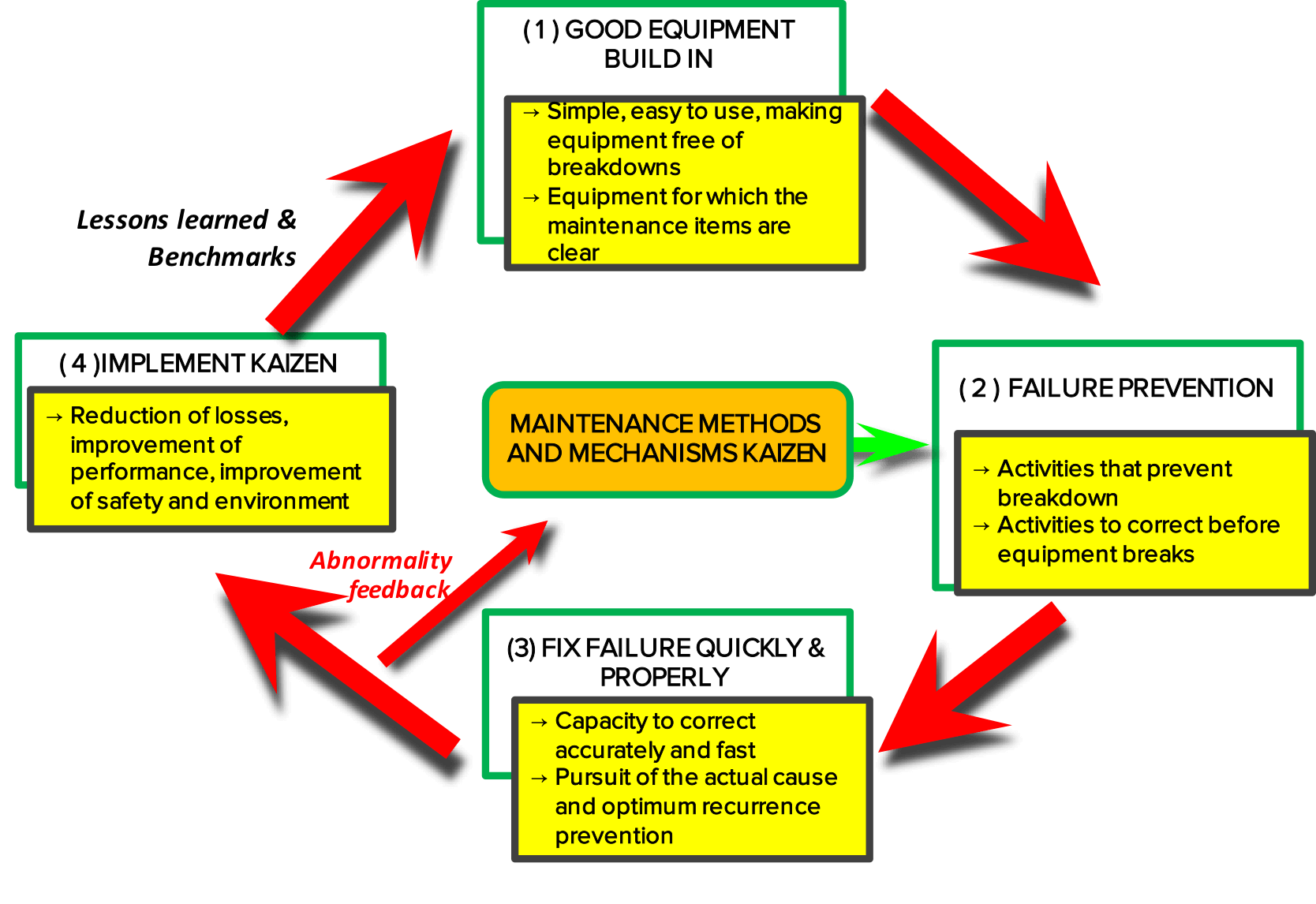

Centerline Program The Centerline Program is a structured methodology that is a component of a total manufacturing strategy It defines a set of technical machine parameters that represent “good run” settings in a production process supported by Manufacturing Excellence Principles, provides a stepbystep implementation methodology, and supports the development of all the prerequisites. Operational excellence is considered as a competitive weapon for firms, both in service and manufacturing Firms should therefore carefully study their operation strategy choices due to the high. The Excellence Model was founded on the values and tools of Six Sigma and incorporates the principles and strengths of Lean Manufacturing, Total Productive Maintenance, Total Quality Management, Maintenance Excellence™ and similar programs that define best practices, into a single, holistic, continuous improvement process.

Manufacturing excellence 1 To bring our industrial operations to World Class Level Introduction To Manufacturing Excellence Presented by YS Lin Email email_address Mobile 6936 2. The Operational Excellence Manufacturing Project Johnson Controls launched a Manufacturing Excellence Strategy in 13 to achieve its vision of becoming the most operationally capable company in the world The centerpiece of the strategy, which was developed by a global cross business unit team, is the Johnson Controls Manufacturing System (JCMS). This approach has been developed from ‘lean manufacturing’ / ‘just in time’ philosophies The model is equally applicable to large or small organisations in both high and low volume manufacturing environment Manufacturing excellence is based on a set of widely established suite of tools and techniques which together make up a model for.

Operational Excellence is a mindset, not a methodology It is the relentless pursuit of finding ways to improve performance andprofitability It seeks to lower risk, lower operating costs, and to increase revenue by ensuring that each and every employee can see the flow of value to the customer and fix that flow before it breaks. 5 Factors for Achieving Manufacturing Excellence in Good Times or Bad Because manufacturing capacity represents a massive investment that is difficult to relocate or sell off, flexibility and the ability to act quickly to market changes are difficult to cultivate That makes them enormously important for a competitive advantage. Manufacturing Excellence Much of this philosophy is based on earlier continuous improvement methodologies, such as Lean Manufacturing, Six Sigma, and Scientific Management The focus of Operational Excellence goes beyond the traditional eventbased model of improvement toward a longterm change in organizational culture.

Get regular updates about Five S, Lean Operations Management, Lean Operations, Lean Management, Lean manufacturing Kaizen Institute India's Blog is a collection of expert insights and industry news to help accelerate your company's growth. The Operational Excellence Manufacturing Project Johnson Controls launched a Manufacturing Excellence Strategy in 13 to achieve its vision of becoming the most operationally capable company in the world The centerpiece of the strategy, which was developed by a global cross business unit team, is the Johnson Controls Manufacturing System (JCMS).

Ducati 4 07 Qxp Association For Manufacturing Excellence

Operational Excellence Powerpoint Template Sketchbubble

Digital Manufacturing S Scaling Potential The Next Normal Mckinsey

Manufacturing Excellence Model のギャラリー

Product Launch Excellence In Lifecycle

Pdf Manufacturing Excellence Approach To Business Performance Model Jesus Cruz Academia Edu

Manufacturing Operational Excellence Opx Concept Arc Advisory Group

Digital Transformation Yokogawa Electric Corporation

Lean Manufacturing Wikipedia

Smart Manufacturing Industry 4 0 Factory 4 0 Smart Factory

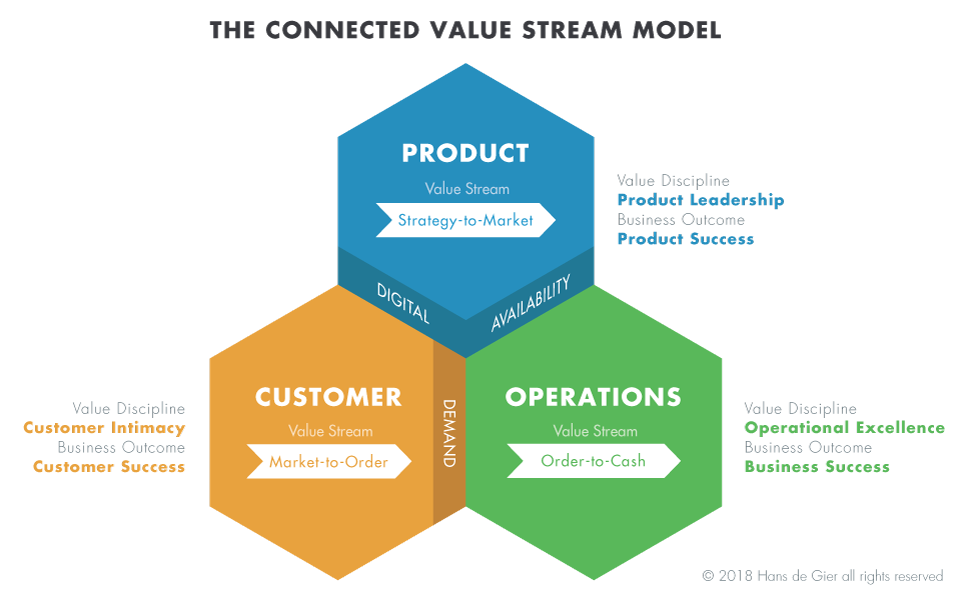

Value Disciplines The 3 Routes To Competitive Advantage

Operational Excellence Assessment Framework For Manufacturing Companies Semantic Scholar

Lean Manufacturing Wikipedia

Sc21 Manufacturing Excellence Process Overview Pdf Free Download

Shingo Principles Organization Development Supply Management Operational Excellence

Pdf Operational Excellence Driven By Process Maturity Reviews A Case Study Of The Abb Corporation

Achieving Excellence Model Operational Excellence

Operational Excellence Lean Manufacturing Leadership

Efqm Model Efqm

How Human Factors Limit Achieving Operational Excellence Consult

The Operational Excellence Manifesto Lenoxcells

1

The 7 Element Operational Excellence Management System Our Big Idea

Is Your Organization Striving For Operational Excellence

What Is Operational Excellence 10 Core Principles

Custom Manufacturing Operational Excellence Model Png Free Transparent Png Images Pngaaa Com

Development Of An Assessment Framework For Operations Excellence Ose Based On The Paradigm Change In Operational Excellence Oe Topic Of Research Paper In Economics And Business Download Scholarly Article Pdf And

Process Excellence Model Platinum Engineered Materials

Value Disciplines Explained With Examples B2u Business To You

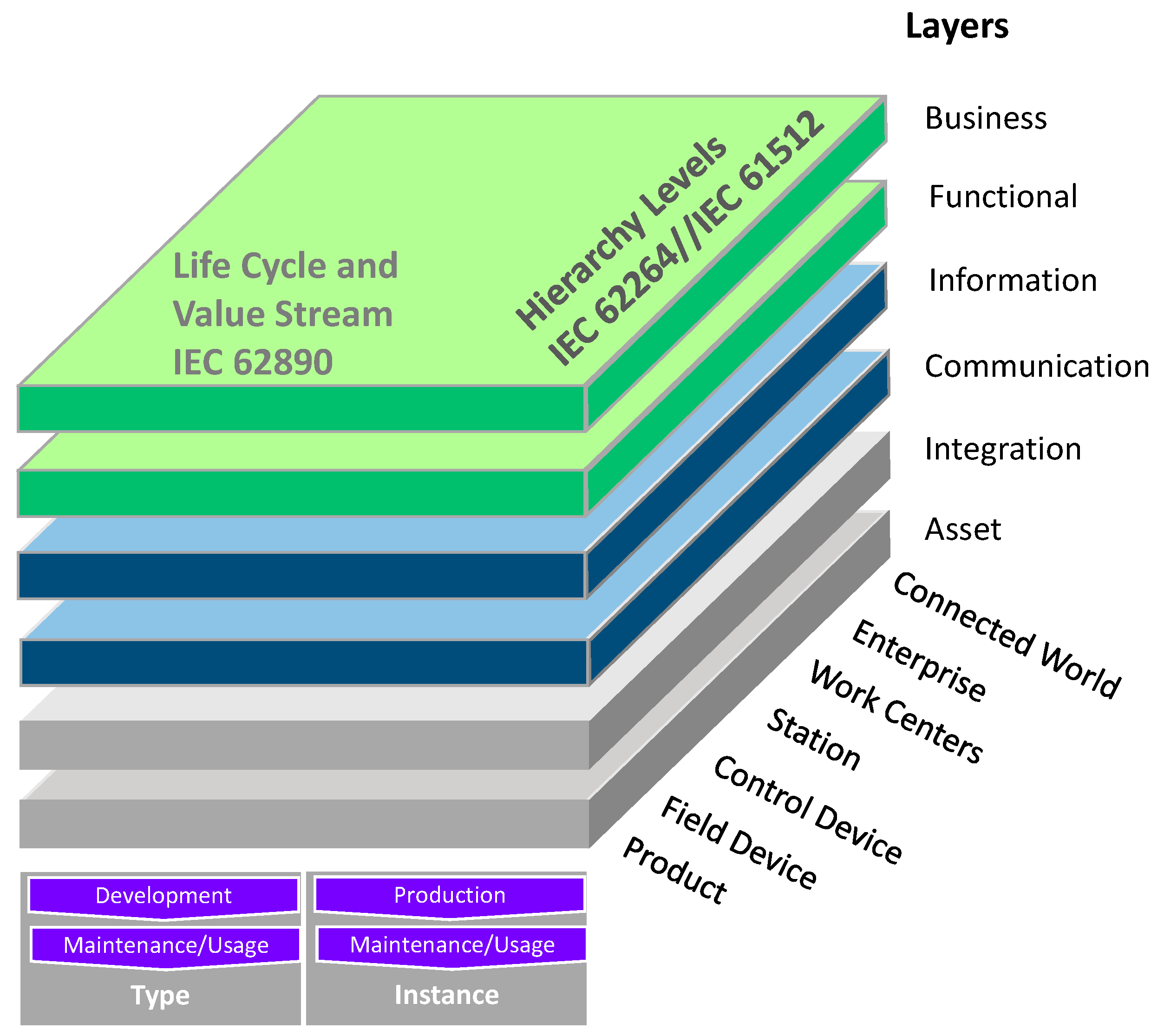

Applied Sciences Free Full Text Reference Models For Digital Manufacturing Platforms Html

Concurrent Digitalized Value Chain The Cdvc Model Page 2

2

Process Reengineering Identified 5 Key Levels Of Operational Excellence Download Scientific Diagram

The Odg Way Ontario Drive Gear

What Is Manufacturing Excellence Sensrtrx Manufacturing Analytics

The Operational Excellence Manifesto Lenoxcells

Plan Do Check Act Management Skills Business How To Plan Management Skills

Accenture Named As A Leader In New Green Quadrant Report For Operational Excellence Digital Services By Independent Analyst Firm Accenture Newsroom

Http Www Vanassen Info Wp Content Uploads Opex In Perspectief Pdf

Q Tbn And9gcqkxtmi1ckqea0jjikak Pgdmpsca Mxelm 4qcmykkfxcvnil2 Usqp Cau

The Role Of Strategy In The Operational Excellence Journey 17 08 10 Quality Magazine

Gartner Blog Network

Bachelorscriptie Voortreffelijkheid In Zuiveren Over De ndachtspunten Voor Invoering Van Operational Excellence Pdf Gratis Download

A Model For Global Manufacturing Excellence Emerald Insight

Road To Reliability Plant Level Manufacturing Excellence Model For Process Manufacturing Industries By Pratik Das

Why You Must Know Your Maturity Level For Real Manufacturing Improvements

The Journey To Manufacturing Maturity Hertzler Systems Inc

Roadmap To Oe Maturity Level 5 Download Scientific Diagram

Philips Annual Report 19 Philips Results

Business Excellence Frameworks By Operational Excellence Consulting

Gproms Products Process Systems Enterprise Process Systems Enterprise

Q Tbn And9gcqgvf9trvidc5wzvafkqolkz4gqz9kmmb8vgt 8k4xmallojn1p Usqp Cau

Pursue The Common Ground In Effective Operational Risk Management And Operational Excellence Industryweek

Operational Excellence Defined Is Right For You

Manufacturing Excellence Ppt Video Online Download

Mesa International Manufacturing Performance Metrics

Competitive Strategies Operational Excellence Customer Intimacy Product Leadership

Our Difference Deacero Summit

Kirk Borne בטוויטר Digital Business Model Transformation And The 3 Horizons Of Digitaltransformation T Co Lnls5demw8 By Schmarzo Bigdata Datascience Analyticsstrategy Ai Machinelearning Datamonetization Ar Vr Iot Iiot

Pdf Operational Excellence And Change Management In Malaysia Context Semantic Scholar

Futuresme Igniting A Movement Amongst European Smes Towards Creating A Sustainable And Globally Competitive Manufacturing Community Futuresme

Operational Excellence Valueinfinity Inc

Achieving Excellence Model Operational Excellence

Introduction Springerlink

Pin By Laura Rene On Business Ideas Operational Excellence Business Problems Lean Six Sigma

Value Disciplines Explained With Examples B2u Business To You

Excellence Framework Consulting Home Facebook

Chevron Oems Chevron Com

Reliability Excellence Rx Life Cycle Engineering

Stage Gate Process Tools Techniques Within Enterprise Excellence Bpminstitute Org

Operational Excellence ऑपर शनल एक स ल स सर व स ऑपर शनल एक स ल स क स व ए In Pedda Waltair Visakhapatnam Starlite Media Id

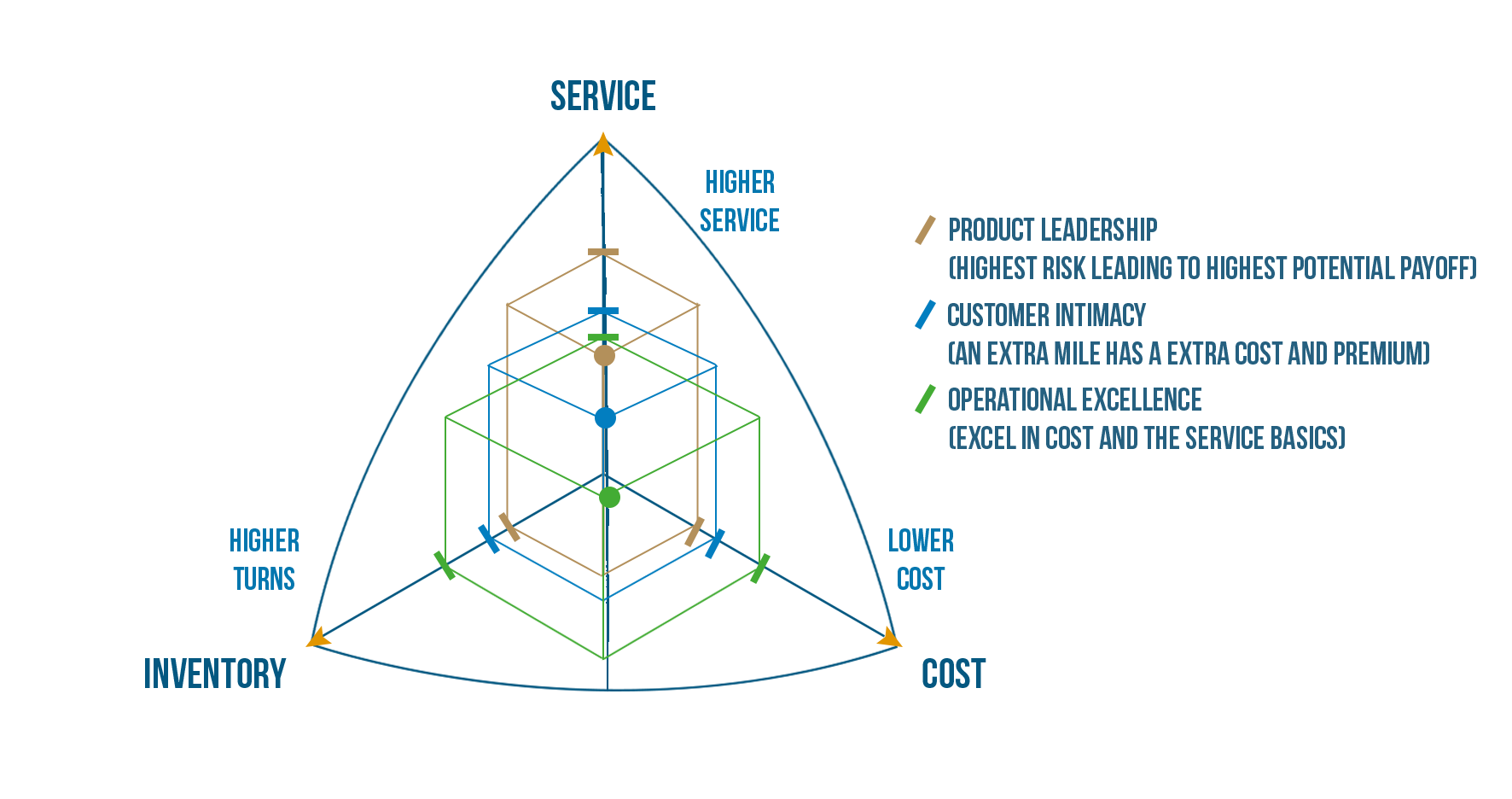

Linking The Supply Chain Triangle To Strategy

Operational Excellence Ppt Operational Excellence Model

8 Steps To Operational Excellence Logbook

One Major Problem With Your Operational Excellence Model

How To Accelerate Growth In The Chemicals Industry Ey Building A Better Working World

Value Disciplines Explained With Examples B2u Business To You

Operational Excellence Omnex India

A Framework For Manufacturing Excellence Emerald Insight

You Say Process Excellence She Says Operational Excellence I Say Pe

Value Stream Mapping Process Excellence Network

The Lns Research Approach Share Learn And Improve

Tpm In Field Training

Key Principles Of Operational Excellence Smartsheet

Introducing A New Way To Achieve Manufacturing Excellence Tooling U Sme S Competency Framework Youtube

Acknowledging Sustained Efforts To Excellence

Operational Excellence Increase Your Efficiency Effectivness Signavio

Operational Excellence Xihorizons

Why Use Value Streams To Design Your System Landscape Syncforce

Pdf The International Journal Of Advanced Manufacturing Technology An Empirical Validation Of Integrated Manufacturing Business Excellence Model Parani Tharan Academia Edu

Ppt Manufacturing Excellence Powerpoint Presentation Free Download Id

Road To Reliability Operational Excellence However You Define It The Foundation Is Reliability Plant Services

1

An Operational Excellence Model And Framework Operational Excellence Consulting Llc

Discrete Manufacturing

Cleaner Production Excellence Model Download Scientific Diagram

Transformational Solutions For Process Manufacturing Excellence November 11

Essay Utwente Nl 1 rntzen Ma Bms Pdf

Operational Excellence In The Rmg Manufacturing

Key Strategy Models By Operational Excellence Consulting

Operational Excellence Mps Meggitt Enabling The Extraordinary

How To Achieve Operational Readiness Techtalk

Back To Basics For True Operational Excellence Reliabilityweb A Culture Of Reliability

Operational Excellence In Process Industries Semantic Scholar

India Manufacturing Awards Methodology Excellence Model