Cip System

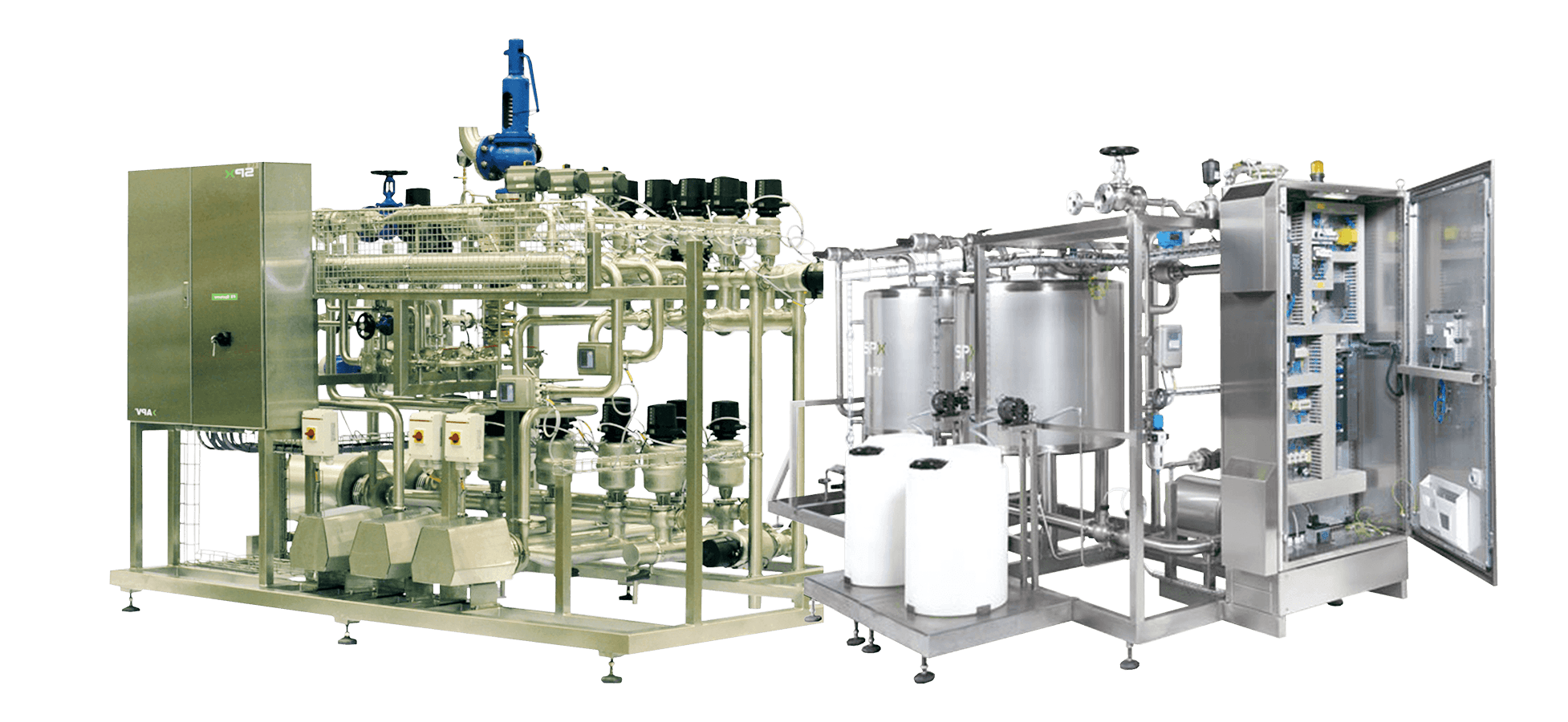

CIP systems INOXPA designs and manufactures optimal CIP cleaning systems for foodprocessing, dairy, chemical and pharmaceutical industries Clean in place systems for each industry and need automatic or manual, static or mobile CIP systems.

Cip system. CIP Systems Tell us what you're cleaning and we'll design the best CIP system for you We know that in order to provide you with the most efficient and effective system, we need to understand your processes and your facilities Is your product liquidsoluble, a solid, or somewhere in between?. BiOZEEN CIP system CleaninginPlace is designed for automatic cleaning ensuring minimal use of water and time CIP system has many benefits to the enduser, some of them to mention are Production downtime between product runs can be minimized Cleaning costs can be reduced substantially by recycling cleaning solutions. Cleaninplace (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly Up to the 1950s, closed systems were disassembled and cleaned manually The advent of CIP was a boon to industries that needed frequent internal cleaning of their processes.

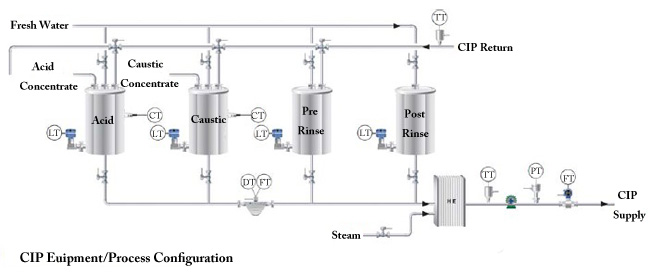

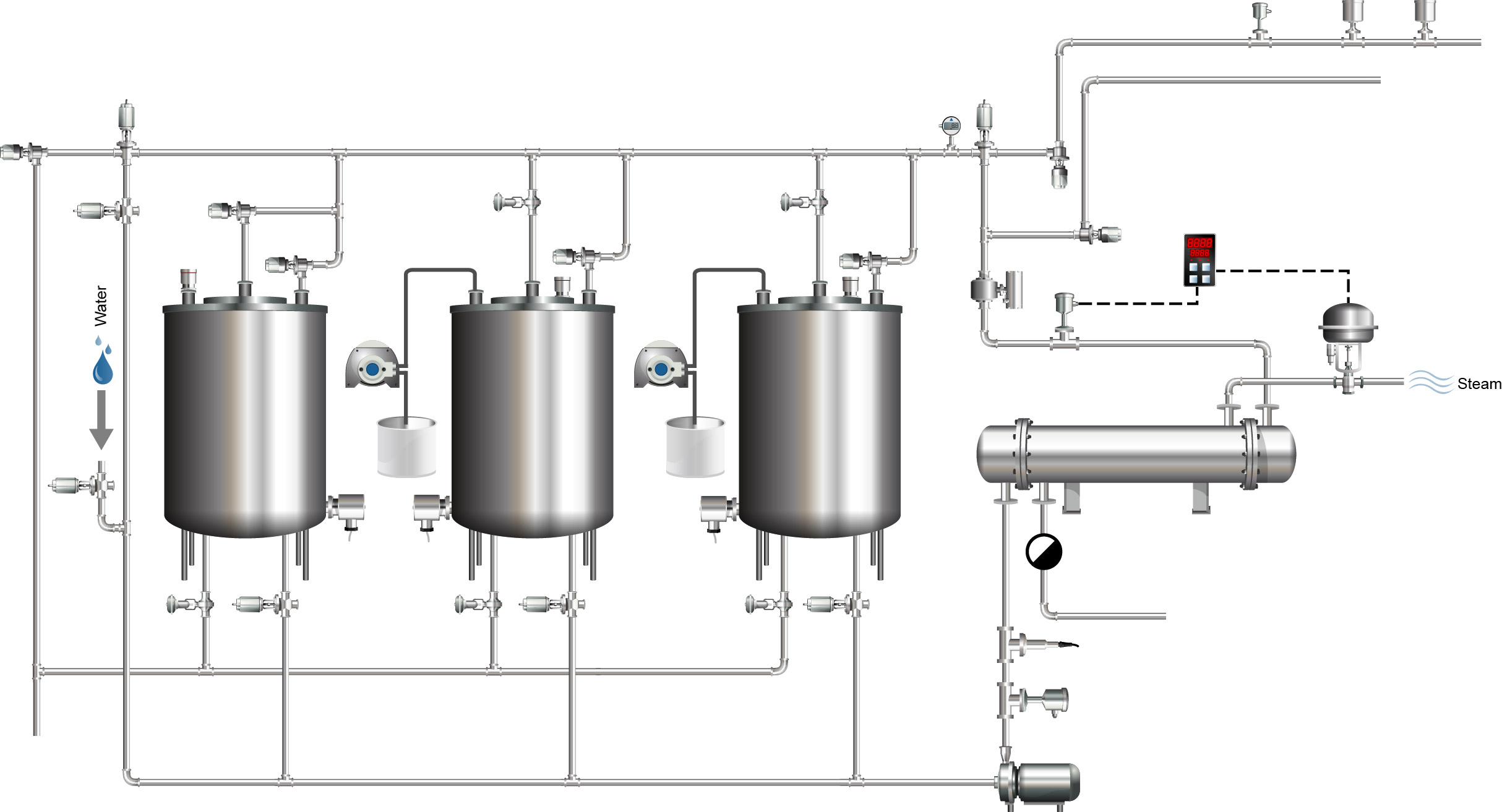

3ea 400Gal CIP System with Insulated heat exchanger, each tank has 144in outside circumference and 58in height, To Include 3ea SVF AERO 2 Mdl S5008V Pneumatic actuator;. Cleaning in place, or CIP, refers to all those mechanical and chemical systems that are necessary to prepare equipment for food processing, either after a processing run that has produced normal fouling or when switching a processing line from one recipe to another Cleaning in place means that cleaning takes place without dismantling the system. CIP Systems are typically meant for cleaning the interior surfaces of process equipment Equipment such as tanks, pipes, and pumps for example It’s usually a highly sophisticated system, with sensors, heat exchangers, pumps and tanks, all to give the user the most effective and repeatable cleaning Some advantages to CIP systems.

CleaninPlace (CIP) system is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassemblyWe design, produce, production, supply and fit Mobile and Fixed CIP and SIP System for sanitization The units are used made, modular, skidded in automated or semiautomated Models as per the expected time cycle for washing and sterilization as a part of cGMP conditions from compact to long fixed MultiTank way. Alfa Laval CIP systems connect directly to your heat exchanger or separator connections and circulate a mixture of heated nontoxic cleaning agents that effectively remove scale, product deposits and biofouling This leaves process surfaces clean and restores the performance of your equipment Modular CIP systems. Clean in place (CIP) is a method of cleaning equipment with minimal dismantling and operator/manual involvement It relies on the principal of applying a suitable detergent or solvent at a suitable flow and/or kinetic energy application, pressure and temperature for a determined amount of time to ensure effective cleaning of the system.

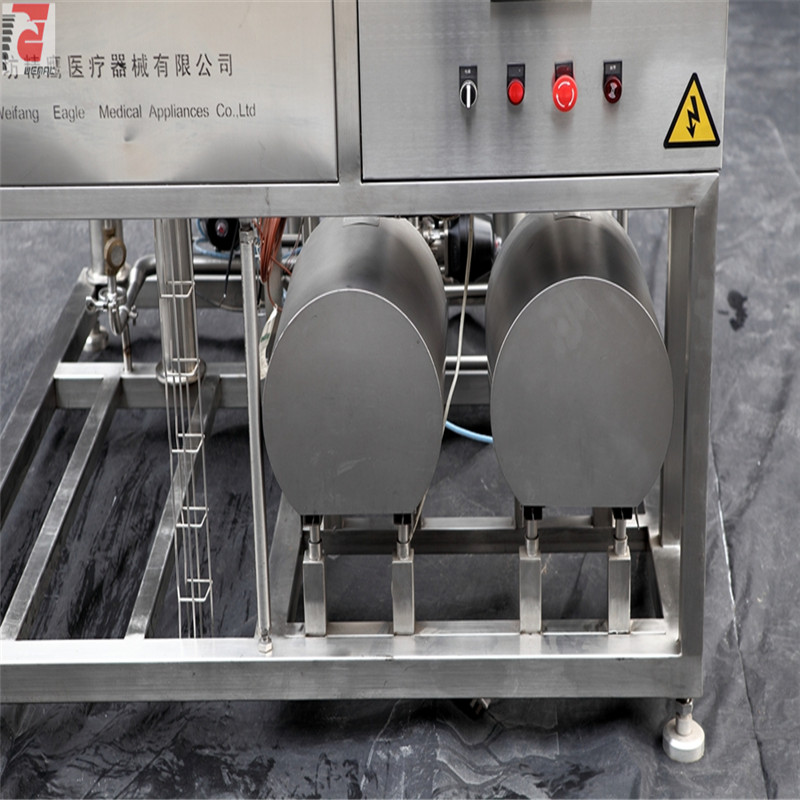

Designing a CIP system begins by sizing the CIP system for sufficient flow and pressure to thoroughly remove residue, reduce cycle times, and rinse effectively Determining proper flow and pressure is dictated by the spray devices and process lines Static spray balls are the most common spray device used in pharmaceutical CIP applications. CIP (Cleaninginplace) System is an automatic machine that is designed to clean and disinfect various processing plants This reliable system is available in manual and automatic option and also meets the stringent hygiene regulations demanded by the food, dairy, pharmaceutical and biological industries. Used CIP Systems Finding the right used CIP equipment for your needs isn't difficult when you come to Federal Equipment Company for help For over 50 years, we've been buying and selling used industrial equipment These years of experience have helped us to become experts in used machinery like used CIP equipment.

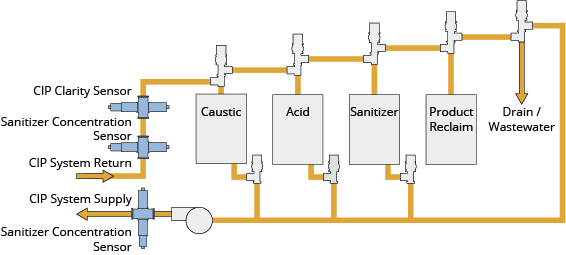

Sanitary Conveying Solution ChainVey’s customized CleanInPlace System is a flexible, stressfree, and automated sanitary conveying solution The CIP cart, in conjunction with the CIP turnaround and drive units, provides a selection of customizable high pressure water, foam, or floodedsystem cleanings. Cleaninplace (CIP) is the system designed for automatic cleaning and disinfecting in these processes Recovery of cleaning solutions contributes significantly to the reduction of chemical and/or wastewater processing costs. A CIP system will consist of vessels for preparation and storage of cleaning chemicals, pumps and valves for circulation of the CIP chemicals throughout the plant, instrumentation to monitor the cleaning process and vessels to recover the chemicals.

CIP units for efficient cleaning of pipeline systems, tanks and processing plants with a choice of tank sizes depending on requirements The CIP MIDI is intended for small to medium CIP applications with a choice of different capacities and sizes, up to a maximum of two CIP circuits per CIP set Available in two standard ranges. Cleaning in place, or CIP, refers to all those mechanical and chemical systems that are necessary to prepare equipment for food processing, either after a processing run that has produced normal fouling or when switching a processing line from one recipe to another Cleaning in place means that cleaning takes place without dismantling the system. Our CIP systems are "smart" meaning that they will keep your chemical concentrations at safe levels so they protect not only your people but also your commercial beer brewing equipment They can be designed to recover chemicals so you are getting the most out of your chemicals, saving you time and money.

New, Used, and Reconditioned CIP Systems Phoenix Equipment has a large inventory of used CIP Systems and other process equipment Call today to receive a quote for any of our CIP Systems from manufacturers such as Cherry Burrell, Strahman, Waukesha, SantasaloSohlberg, and many others Also check out our Chemical Plants for Sale, Refinery Units, Power Generation Plants, and Gas Processing Plants. If you’ve come to this part of our website on purpose, you will already know that “CIP” is short for “Clean In Place”, and is a critical requirement for any food or beverage processing facility. Cleaninplace (CIP) is the system designed for automatic cleaning and disinfecting in these processes Recovery of cleaning solutions contributes significantly to the reduction of chemical and/or wastewater processing costs.

CIP Systems Federal designs, builds, installs and programs standard and custom CleanInPlace (CIP) skids for both level and weight fillers Custom designed CIP skids are ideal for customers that have space constraints in their facility. CIP systems deliver cleaning solutions followed by rinse water through process equipment and piping, without requiring disassembly of the system Equipment commonly cleaned by CIP skid systems include tanks, mixers, heat exchangers, pumps, freezers, and fillers. 1413 CleanInPlace (CIP) System CIP can be defined as the process of circulating various chemical solutions along with water through the process equipments in the assembled state 16 The aim of circulating these chemical solutions under higher turbulence is to remove solid debris and micro organism.

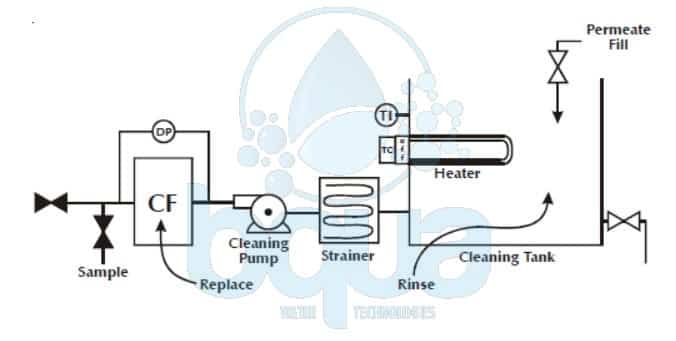

A Clean in place CIP system is a very effective method widely used by RO Systems manufacturers and operators to preserve and also clean fouled or scaled reverse osmosis system RO membranes Using certain chemicals and following procedures guided by each RO Membrane manufacturers. CIP systems deliver cleaning solutions followed by rinse water through process equipment and piping, without requiring disassembly of the system Equipment commonly cleaned by CIP skid systems include tanks, mixers, heat exchangers, pumps, freezers, and fillers The cleaning in place method is much more efficient and effective than removing and manually cleaning each piece of equipment and all of the connected piping and valves, you will spend less time cleaning and more time processing. EPIC completed the CIP system integration, controls programming, fabrication and system installation After product runs, a clean in place skid system is used to washout the process equipment Wastewater collected in Steris’s aggregate runoff pits is pumped into a treatment tank The tank is filled with dip pipes to prevent excessive foaming.

Efficiency through individual configuration We design each CIP system to have the correct cleaning throughput, pressure, temperature, pipe crosssections and external pressure losses to suit your individual system requirements Our CIP systems are manufactured in the proven BrauKon quality They are easy to operate, save time, reduce costs and lower the environmental impact. Sanitary Conveying Solution ChainVey’s customized CleanInPlace System is a flexible, stressfree, and automated sanitary conveying solution The CIP cart, in conjunction with the CIP turnaround and drive units, provides a selection of customizable high pressure water, foam, or floodedsystem cleanings After rinsing, the cart pumps warm, dry air throughout the system to dry the entire ChainVey for quick resumption of operation. CIP Systems CIP systems are widely used in the food and beverage industries They make the cleaning and sanitation of tanks, pipelines and process equipment easier by providing a process that requires no dismantling of the equipment Pollution Prevention (P2) Practices.

Our cleaninplace (CIP) systems will help you optimize your production and cleaning schedule Each system is custom designed to meet your unique requirements Our cleaninplace system features include Single or multiple tank systems for rinse, acid or caustic wash, recovery, and reclaim or reuse. Operational Efficiency IPEC CIP Systems are designed and built for efficient use of water, chemicals, and energy Our customers rely on dependable and repeatable results to minimize production downtime. CIP systems INOXPA designs and manufactures optimal CIP cleaning systems for foodprocessing, dairy, chemical and pharmaceutical industries Clean in place systems for each industry and need automatic or manual, static or mobile CIP systems.

CIP is a closed system where recirculating cleaning solution is applied (often with nozzles) that cleans, rinses and sanitises equipment The CIP system is usually automatically controlled and the cleaning sequences are given the optimum timing for efficient cleaning of all parts of the plants Differents types of CleaninginPlace systems exist. The terms WIP and CIP refer to the process of cleaning equipment and machinery without requiring disassembly Cleanability is a factor that goes into the design of every piece of process equipment that we create and sell Machinery in the pharmaceutical industry already requires indepth cleaning methods and cleaning solutions. CIP system is a device established to prevent product fluids and auxiliary fluids from being contaminated by microorganism and bacteria on storage tanks, pipes, and equipment.

CIP Systems Here at Rodem we have spent the past four decades improving sanitary processing operations and efficiency One great way to better your process and generate savings is to invest in a CleaninPlace (CIP) System The benefits of the right CIP system are limitless. The Cahn–Ingold–Prelog (CIP) sequence rules, named for organic chemists Robert Sidney Cahn, Christopher Kelk Ingold, and Vladimir Prelog — alternatively termed the CIP priority rules, system, or conventions — are a standard process used in organic chemistry to completely and unequivocally name a stereoisomer of a molecule. CIP System BiOZEEN CIP system CleaninginPlace is designed for automatic cleaning ensuring minimal use of water and time CIP system has many benefits to the enduser, some of them to mention are Production downtime between product runs can be minimized Cleaning costs can be reduced substantially by recycling cleaning solutions.

CleanInPlace (CIP) Systems CleanInPlace (CIP) Systems offer important advantages to processing facilities, from efficient, reliable and repeatable cleaning of process equipment and piping at lower costs to improved product quality. CIP (CleaningInPlace) Systems are designed for automatic cleaning operation or disinfecting a process line without involving major disassembly work A well designed CIP system allows one part of the process line to function normally, while the other line is being cleaned or disinfected. CIP Systems Hysysco Integrated CIP Systems SAVE YOU TIME AND MONEY!.

Cleaninplace (CIP) is an automated method of cleaning the interior surfaces of pipes, tanks, lines, process equipment, and associated fittings without requiring the operator to disassemble the equipment Implementing a CIP system that is engineered for your specific plant application and utility requirements allows the operator to spend less time cleaning and more time on other tasks required in his or her role. Used Mork Process portable CIP system, model CIP 12/285, rated 55 GPM at 100 psig max, with AllenBradley touchscreen controls, 480 volts, 3 phase, serial# MP1636, built 06 Item Specifications Material of ConstructionStainless Steel. CIP Systems pump cleaning, rinsing, and sanitizing solutions through the same piping path as the product to eliminate product soil from all internal surfaces Advantages of a CIP System Minimizes Mistakes Automating cleaning reduces the chance of human error that can contribute to an unsafe product.

This is why, when thinking about medium and large facilities that require a fully automatic cleaning process, INOXPA designed a range of static framemounted CIP systems to help to clean plants, eliminate impurities, and reduce bacteria levels There is a version that cleans one line and another that simultaneously cleans two lines. CleanInPlace (CIP) systems are automated systems used to clean the interior surfaces of food and beverage process pipes, processing vessels, tanks, spiral freezers, mixers, blenders, homogenizers, roasters and associated fittings, without disassembling the process. CleanInPlace (CIP) Systems CleanInPlace (CIP) Systems offer important advantages to processing facilities, from efficient, reliable and repeatable cleaning of process equipment and piping at lower costs to improved product quality The sanitary design of the Budzar Industries CIP system tanks, pumps, heaters, valves and orbital welding ensures the integrity of the equipment and cleaning process.

Cleaninplace(CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filtersand associated fittings, without disassembly Up to the 1950s, closed systems were disassembled and cleaned manually The advent of CIP was a boon to industries that needed frequent internal cleaning of their processes. Designed with the highest level of hygiene and the smallest use of resources in mind Finding the right cleaning in place (CIP) solution for your plant is essential for the ultimate success of your manufacturing processes High product quality and safety, increased production time, less downtime for cleaning and environmental efficiency can only be achieved with a CIP system that responds perfectly to your needs. Cleaninplace (CIP) technology can clean appropriately designed process equipment and interconnecting piping without disassembly or reconfiguration CIP methodology and equipment developed in the 1950s for dairy plant processes, and its implementation greatly reduced manual intervention and time required to clean process equipment, while improving quality and extending product shelf life.

CIP SYSTEMS CIP Systems are typically meant for cleaning the interior surfaces of process equipment Equipment such as tanks, pipes, and pumps for example It’s usually a highly sophisticated system, with sensors, heat exchangers, pumps and tanks, all to give the user the most effective and repeatable cleaning Some advantages to CIP systems. ‘Neelam Industries’ CIP system is tailor made system which is used for cleaning / descaling the precious machines and equipments to avoid down time This consists of a Stainless steel 316 Vessel, recirculating pump,,SS 316 corrugated flexible hose pipe with all necessary accessories. Since the 1950s, CIP has evolved to include fully automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition and specially designed spray nozzle systems Simple, manually operated CIP systems can still be found in use today.

Operational Efficiency IPEC CIP Systems are designed and built for efficient use of water, chemicals, and energy Our customers rely on dependable and repeatable results to minimize production downtime. The modern cleaninplace (CIP) system skid is cleverly designed and built to last CIP is a method of cleaning sanitary process lines, vessels, and equipment commonly used in process plants The process of cleaninplace (CIP) involves passing a cleaning fluid across a surface to remove product soils. Cleaninplace (CIP) systems are an assembly of mechanical components and devices utilized to combine water, chemicals and heat to create cleaning solutions These chemical cleaning solutions are pumped or circulated by the CIP System through other systems or equipment in order to clean them As the name suggests, the intent of a CIP System is to provide a cleaning function to other process systems or equipment without having to move it or take any of it apart.

CIP System / SIP System 30 CleaninPlace (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassemblyThe benefit to industries that use CIP is that the cleaning is faster, less labor intensive and more repeatable, and poses less of a chemical exposure risk to people. Cipsystem ManufacturerUsed cip system 2 tank cipsystem, 10 gallon tank, 1 60 gallon tank, rosemont control, 15 hp fristam pump, 625” definox air valves, 12” endress hauser flow meter, 1 stainless heat exchanger 8” diam x 5’6 long, all skid m $25,000 Harrodsburg, KY, USA. CIP systems are widely used in the food and beverage industries They make the cleaning and sanitation of tanks, pipelines and process equipment easier by providing a process that requires no dismantling of the equipment Pollution Prevention (P2) Practices.

1ea Ampco Mdl ASDC Pump with 10HP electric motor, aprox weight 1500lbs, dimensions 84inL x 30inW x 84inH. Cleaninplace (CIP) systems use a mix of chemicals, heat, and water to thoroughly clean process pipes, vessels, and machinery without the need to dismantle the entire setup Several industries rely heavily on CIP, particularly those requiring optimal sanitation and hygiene throughout critical processes. Paul Mueller Company specializes in cleaninplace (CIP) systems that are custom designed to meet your needs and requirements Our CIP systems are "smart" meaning that they will keep your chemical concentrations at safe levels so they protect not only your people but also your commercial beer brewing equipment.

A cleaninplace (CIP) system is the first line of defense, helping to drive operational efficiency, ensure that processing equipment is clean, and protect your bottom line mobilead name=”Advert 1″.

China 500l Cip Cleaning Machine Cip System Cip Tank Automatic Cip China Cip Cip Cleaning Machine

Clean In Place Guidelines For Choosing The Right Type Of Cip System

China 300l 5000l Cip Tanks For Juice Dairy Processing Line Cip System China Cip Cleaning System Cleaning Machine

Cip System のギャラリー

Cip System From China Cip System Manufacturer Supplier Zheng Jiu Machinery Manufacturing

Mobile Cip System Clean In Place China Cip Mobile Cip Made In China Com

Automatic Cip System Capacity 500 5000l Rs Unit Santosh Engineering Works Id

China Automatic Cip System Manufacturers Cost Price Automatic Cip System Pictures Zhongbo

Fischer Maschinen Und Apparatebau Gmbh Cip System

Two Tank Cip System Sani Matic Inc

Cip Is A Food Safety Must But Can It Be Optimized To Increase Your Bottom Line Result Schneider Electric Blog

Clean In Place Systems Highland Equipment Inc

Schwarte 3x Tank Cip System Machinery World

Clean In Place An Overview Sciencedirect Topics

Cip System Sick

Cip Systems Scanjet Systems

Cip Systems Hysysco The Hygienic Systems Company

Cip System Apeq Process

Cip System For Beverage Vekamaf Industry Experts

Cip Systems New Feature Offers Sterilising On The Move

Static Cip Cleaning System For Dairy And Food Industries Inoxpa

C I P Technology And Systems Operation And Advantages Adamant Valves

Cip System Cleaning In Place Cip System Manufacturer From Pune

The Hyclean Cip System

Compact Clean In Place

Automatic Cip Cleaning System Cip Washing System Fresh Milk Cip System Cleaning In Place Buy Fresh Milk Cip System Cip Washing System Automatic Cip Cleaning System Product On Alibaba Com

Cip Cop Systems W M Sprinkman

Is Your Cip System Really Efficient Ecn Automation

Clean In Place Cip Systems Sani Matic Inc

Automatic Cip System Auxiliary Equipment Pladot Mini Dairy

Cip Cleaning System For Pharmaceutical Industry Inoxpa Cip Systems

Clean In Place System Cip For Food Conveyors

Mobile And Manual Cip System Inoxpa Manual Clean In Place

G0grsdfkndkrzm

Single Tank Cip System At Rs 1 No Bengaluru Id

Single Tank Cip System Sani Matic Inc

Two Tank Cip System Sani Matic Inc

Automatic Mobile Cip System Inoxpa Automatic Clean In Place

Cip Star System Brewhouse

Model Manufacturing Vessel And Cip System Download Scientific Diagram

Cip Systems Cleaning In Place Ams Modules Made In Germany

Cip System Eurolux

Smart Cip System Improves Performance Reporting Rockwell Automation

Equipping A Cleaning In Place Cip System With Flowmeters Krohne Group

Bestand Cip System Example Svg Wikipedia

Clean In Place Cip Cleaning System

Cip System Sick

China Cip System China Clean In Pipe Self Clean System

Cip System Wiegers Process Innovations

Cip System Steinecker Eurolux

1

Multi Circuit Cip System Sani Matic Inc

Cip Systems Supply Professional Energy Efficient Fu Chen Technology

Cip Star System Cold Process Area

Cip System Brewing Paul Mueller Company

Cip System Clean In Place China Cip System Clean In Place Made In China Com

Installation Debugging And Use Maintenance For Cip System

Equipping A Cleaning In Place Cip System With Flowmeters Krohne Group

Equipping A Cleaning In Place Cip System With Flowmeters Krohne Group

Cip Systems Scanjet Systems

Cip System Yogurt Machine Cleaning Equipment Taizy Yogurt Machinery

Cip System Jinan Zhuoda Machinery Equipment Co Ltd

Cleaning Agent Storage Tank Of The Cip System Level Limit Level Vega

Used Ecolab Cip System Stock Youtube

Single And Multiple Tank Clean In Place Or Cip Systems

Cip Systeem D S Process Solutions B V

Cip System

What Is A Clean In Place Cip System Hapman

Cip Systeem Shuffle Mix

Cip System

Ved Engineering Semi Automatic Cip System Rs 9000 Piece Ved Engineering Id

Measuring The Electric Conductivity By Use Of Clean In Place Cip System Yokogawa Nederland

Clean In Place Systems

Clean In Place System Cip Ventus Process Engineering

Cip Systems And Cop Tanks Lake Process Systems Inc

Cip System Cip Cleaning System Split Type Cip System Fermentation Tank Cip System Filling Bottling Line Capper Sealer Fermentation Packaging Machinery Cleaning

Pharmaceutical Cleaning In Place Cip System For Sale Wemac S0 Wemac Beer Equipment

Clean In Place 5 Steps In A Common Food Dairy And Beverage Cip

Shuffle Mix Fully Automatic Cip System Youtube

Vertical Cip System

Solutions For Successful Clean In Place Cip Burkert Fluid Control Systems

5 In The Single Path Cip System A Freshly Made Up Cleaning Solution Is Download Scientific Diagram

Cleaning In Place Cleaning For Lab And Pilot Equipment Omve

Equipping A Cleaning In Place Cip System With Flowmeters Krohne Group

Clean In Place Membrane Cleaning Cip System Bqua

Automated Cip System Youtube

Kean Automatic Cip System China Control Cip Cleaning System Fully Automatic Control Cip Cleaning System Made In China Com

Clean In Place Station Cip Systems

Cip System Cip System Manufacturer Cip System Supplier

Cleaning In Place Cip System Inoxtorres Sl Pdf Catalogs Technical Documentation

Centralized Cip System Sagafluid

Cip System From China Cip System Manufacturer Supplier Zheng Jiu Machinery Manufacturing

Koss Industrial Koss Industrial Custom Stainless Steel Processing Equipment Products Services

Durable Automatic Cip Cleaning System For Sale Sterilization Equipment Wemac S004 Wemac Beer Equipment

Clean In Place Process Optimization Monitor Sanitizer Concentration

Cip Systems For The Dairy Sector

Cip System Cleaning In Place Ibc Machine

1

Measuring The Electric Conductivity By Use Of Clean In Place Cip System Yokogawa Nederland

Silver Color Cip Clean In Place System Portable Cip System For Tomato Paste Equipment

Cip For Pharmaceutical Process Plants

1

Cip System Archives Bqua

Cip Sip Food Cleaning Systems Hrs Heat Exchangers

Q Tbn And9gctzlq Hb74tca4piqjopvyxwodpwdcxto4nwen9pxs6zcjg9s6h Usqp Cau