Peel Test

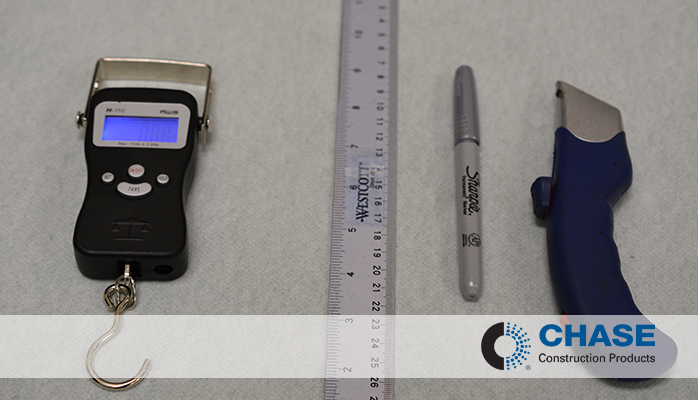

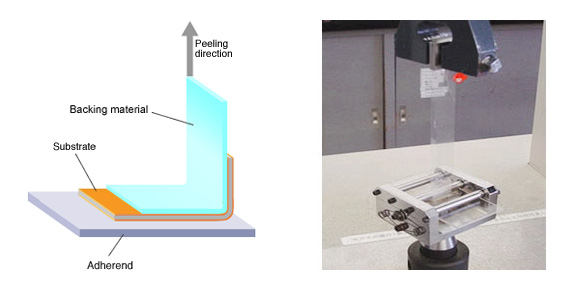

Common test of a release liner or tape is called a peel testThis test involves the peeling of a test sample at a set speed and angleThe apparatus measures the force needed to peel the sample The output of the test is the amount of force (grams are the typical units), average force, and peak force.

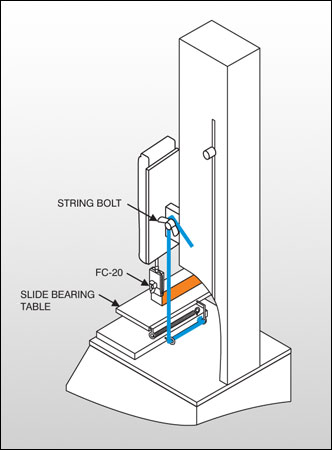

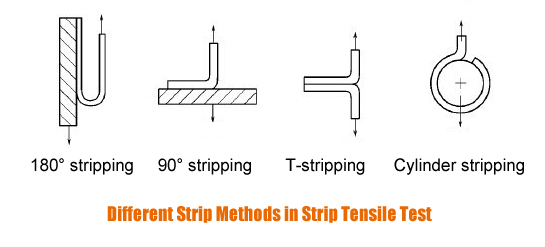

Peel test. Imada offers motorized peel testers in vertical or horizontal configurations The motorized test stand, digital force gauge and peel fixture apply tension to a safety seals, tapes and laminates Special attachments and fixtures facilitate 45°, 90°, 180°, ‘T’ and rotary peel tests. The peel test can also be modified to measure the peel of an adhesive on different substrates such as PE and cardboard upmraflataccom upmraflataccom El ensayo 'peel' también puede ser modificado para medir la adhesión del adhesivo sobre diferentes sustratos como PE y cartón. AASTM D903 180 Degree Peel Test 100P250 Peel Tester is recommended for ASTM D903 The 100P250 consists of a vertical load frame, an electromechanical actuator, load cell, a tocuhpad test controller, XY test software and peel grips For ASTM D903, we would configure a small capacity load cell (10 or 25 pound) for this low force peel test.

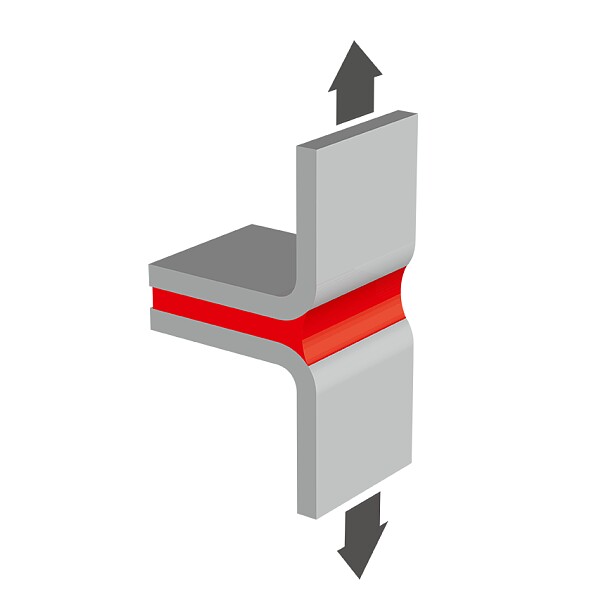

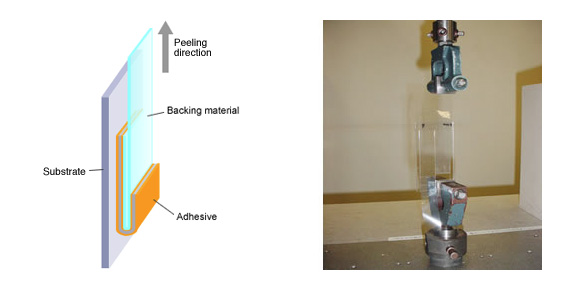

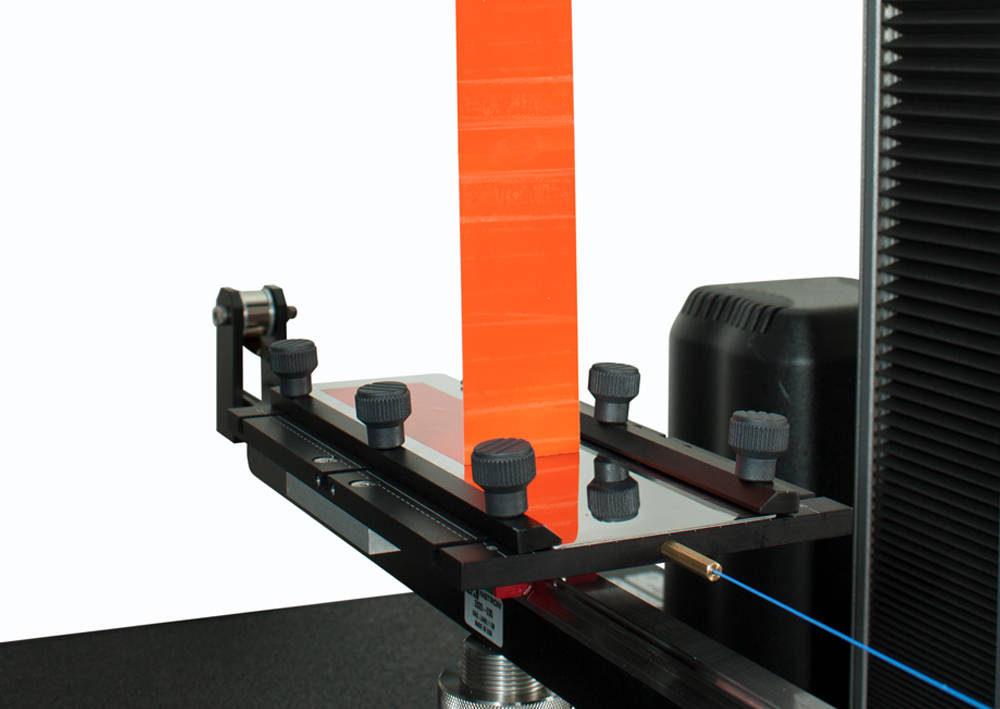

The peel adhesion test is used to determine the force required to debond two components joined by an adhesive The test result, also known as bond strength, is generally represented as N (force to debond) / 25mm or 50mm (depending on specimen width) The peel adhesion test can be used for. Test Summary Our goal is to use Press n Peel film as a onestep way to get a multitonal, photographic intaglio print In traditional tonal etching the plate is coated with an aquatint ground and etched in stages, creating various depths in the plate This film presents an opportunity to nix out the stepby step biting process needed to produce. The 90° peel test fixture consists of a bearingmounted sled that is linked to the testing machine’s crosshead by a cable and pulley system This fixture has a Tslotted sled that allows the substrate clamps, which secure the substrate to the sled, to adjust to a variety of substrate widths.

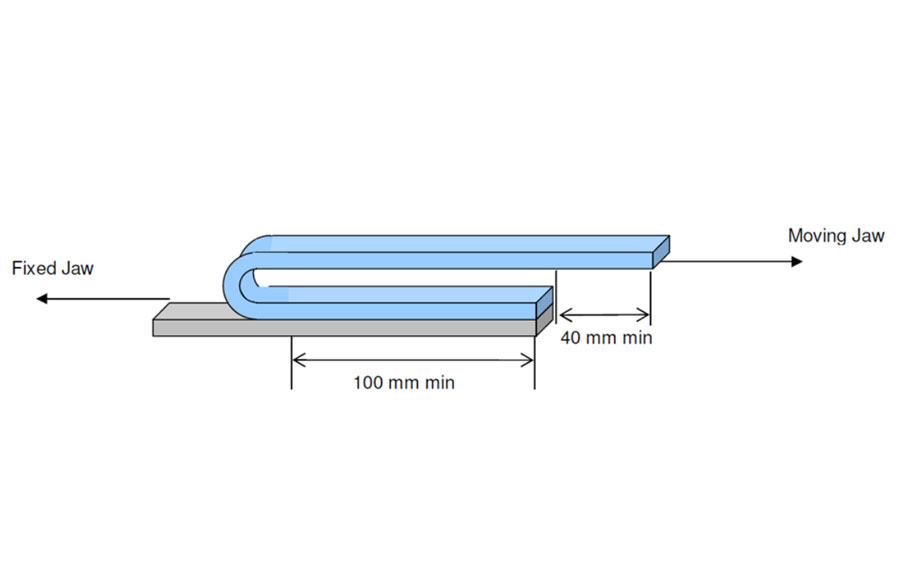

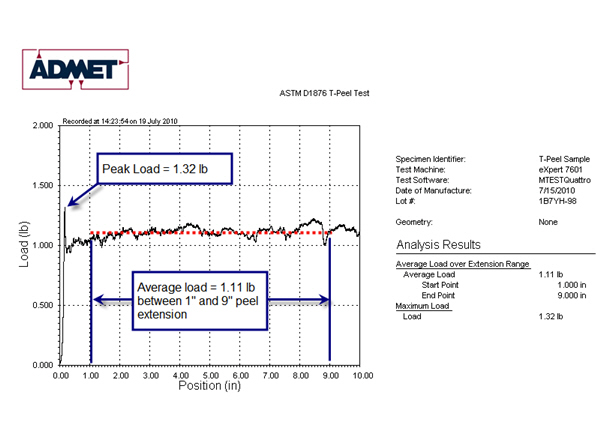

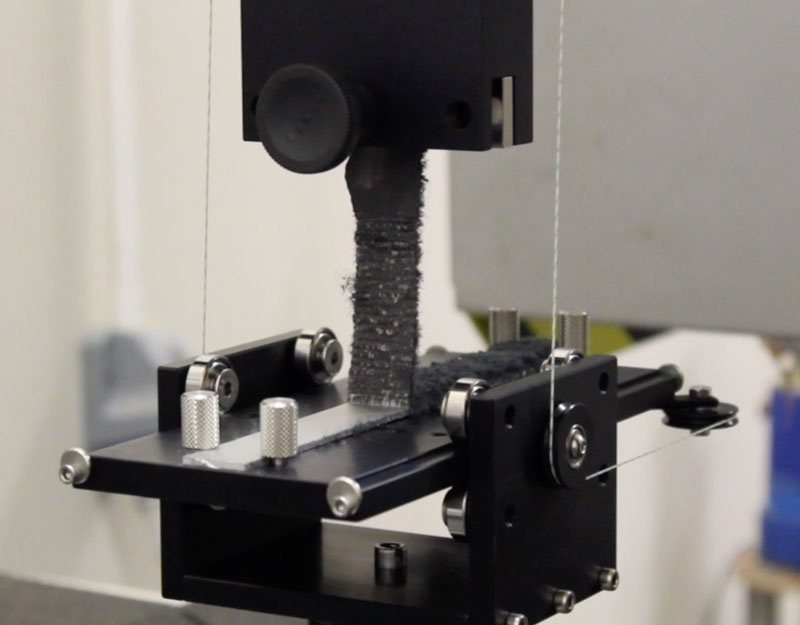

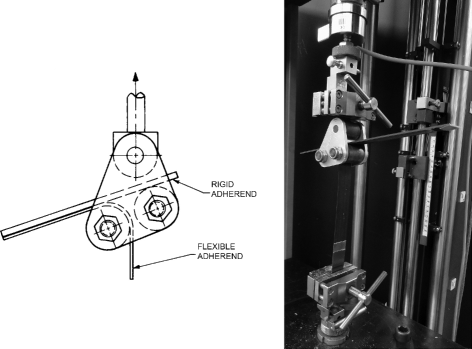

This test method is primarily intended for determining the relative peel resistance of adhesive bonds between flexible adherends by means of a Ttype specimen using a tension testing machine The bent, unbonded ends of the test specimen shall be clamped in the test grips of the tension testing machine and a load of a constant head speed shall. C6H Friction / Peel Tester C6H Friction / Peel Tester can be used to test coefficient of static and kinetic friction of plastic films, sheets, foils, paper, cardboard, woven bags, fabric (fabric style test), metalplastic composite strip/belt for communication cable, convey belt and textile, as well as peel strength test of adhesive laminated products, medical adhesive bandage, release. Peel test for a flexiblebondedtorigid test specimen assembly 180 degree peel FINATFTM1 – Peel adhesion (180°) at 300 mm per minute FINATFTM3 – Low speed release force ISO – Packaging for terminally sterilized medical devices – Part 1 Requirements for materials, sterile barrier systems and packaging systems.

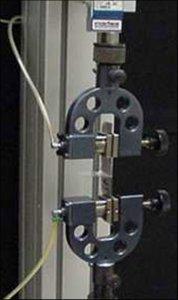

180° peel test using G1008 manually tightened grips 180° peel test using G1046 pneumatic grips 90° peel test using G1109 fixture 180° degree peel test using a G1008 upper grip, G lower grip, and a support plate Loop tack test using G1098 fixture 11 Dixon Avenue Copiague, NY USA. Learn how to peel test adhesive bonds with the best equipment for ASTM D903. There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests Peel tests are common for tapes, labels, coatings, and other bonded materials There are three main types of peel tests including 90 degree peel test, 180 degree peel test, and a TPeel test.

Tensile strength testing device;. The peel test measures the force required to peel apart a 1inwide sample strip cut from the seal material This test has some disadvantages It is timeconsuming because many strips have to be cut from a package in order to get a true measure of the seal strength The sample strips may not contain a weak spot that would be present in the pouch. Peel Plate EC Test Generic Ecoli, considered a fecal risk indicator, is a subset of coliform and are differentiated with the Peel Plate EC formulation Peel Plate EC are AOACRI validated for a number of dairy products, meat rinses, water testing, and environmental sampling.

Peel testing gives information about the bond strength created between an adhesive and a substrate Standards ASTM D903, ASTM D1876, ASTM D3330, ASTM D6862. Peel adhesion is the force required to remove a pressure sensitive adhesive from a testing plate or its own backing material The goal of a peel adhesion test is to determine the adhesive strength level of the material between two materials and is measured in ounces per one inch of tape. Mark10 Peel Testers consist of several components, each of which are available separately Configure your peel tester from a wide range of force gauges, test stands, grips, and accessories See the list of items below for details Shown at left ESM303 test stand with Series 5 force gauge and G1008 film and paper grips.

When testing adhesion between rubber and rigid materials, use a tension or peel procedure and follow ASTM D429 standards ASTM D(10) Adhesive Bonds, Peel or Stripping Strength For testing the peel or stripping strength of adhesive bonds, use manual screw or pneumatic action grips with rubber coated or smooth flat faces. Peel testing is used to assess the bond quality and is a simple way of determining the adhesion strength of a material, especially in the case of a thin film deposited on a substrate By measuring the tension characteristics between the adhesive and the adherend surface, it is extremely useful in assessing the effects of processes (eg surface treatment, sterilisation) or reallife. ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials This guide is designed to introduce you to the basic elements of an ASTM D903 test and will provide an overview of the testing equipment, software, and specimens needed.

Peel Strength of Metallic Clad Laminates 12/94 TM 2481 Peel Strength, Metal Foil (Keyhole Method for Thin Laminates) 01/86 TM 24A Peel Strength of Metallic Clad Laminates at Elevated Temperature (Hot Fluid Method) 12/94 TM 24A Peel Strength of Metallic Clad Laminates at Elevated Temperature (Hot Air Method) 12/94 TM 2484. 10 Scope This test method is designed to determine the peel strength of metallic cladding when tested in the following conditions, ‘‘as received,’’ after thermal stress, and after exposure to processing chemicals;. Peel adhesion is defined as the force needed to “peel” an adhesive tape from any given surface, whether flexible, smooth, or rigid This “peel” force is always and only measured across the width of the taped substrate, making it the more difficult separating force to resist.

Test Summary Our goal is to use Press n Peel film as a onestep way to get a multitonal, photographic intaglio print In traditional tonal etching the plate is coated with an aquatint ground and etched in stages, creating various depths in the plate This film presents an opportunity to nix out the stepby step biting process needed to produce. ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials. There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests Peel tests are common for tapes, labels, coatings, and other bonded materials There are three main types of peel tests including 90 degree peel test, 180 degree peel test, and a TPeel test.

These test methods cover the measurement of the peel adhesion of single and doublesided pressuresensitive tapes Before conducting ASTM D3330, it is important to read the entire specification Standards can be obtained from appropriate standard authorities. The results of a linearelastic analysis to determine the phase angle at the tip of an interface crack in the peel test are presented in this paper The phase angle is fairly insensitive to the peel angle and, when the film and substrate have identical elastic properties, the modeI and modeII components of the cracktip stress field are. Peel tests are the most common test procedure performed on labels, tapes, coatings & other bonded materials There are different types of peel test such as 180degree peel test, 90degree peel test, etc 90 Degree Peel Test or 180degree peel test are commonly used where flexible materials such as adhesives and tapes.

And to evaluate the base laminate material after the peel strength test is completed for degradation due to the conditioning. The peel plot will be an important aspect of data retrieval and therefore we highly recommend our XyPlot software If you would rather see the data in realtime and study the peel interface at the same time, we would provide you with our XyLive Software ASTM D903 Peel Test Accessories ASTM D903 requires vice grips to hold the sample in place. Test Summary Our goal is to use Press n Peel film as a onestep way to get a multitonal, photographic intaglio print In traditional tonal etching the plate is coated with an aquatint ground and etched in stages, creating various depths in the plate This film presents an opportunity to nix out the stepby step biting process needed to produce.

Peel testing gives information about the bond strength created between an adhesive and a substrate Peel adhesion can also be extended to apply to thermal bonds or other types of mating between materials Because substrate cleanliness is so important to gathering reliable data, appropriate measures must be taken to ensure freedom from dirt. There are two primary reasons for performing a peeling test 1 Assessing the uniformity of the adhesion of a given type of pressure sensitive adhesive interface, which indicates a 2 Distinguishing between acceptable and unacceptable criteria, by determining the adhesive strength range which. Peel Memorial Centre for Integrated Health and Wellness Lynch Street, Brampton (map) Peel Memorial has both a COVID19 Testing Centre as well as a COVID19, Cold and Flu Clinic Check the criteria to find out where you should go COVID19 Testing Centre Use the south side entrance and dedicated outdoor parking next to the entrance.

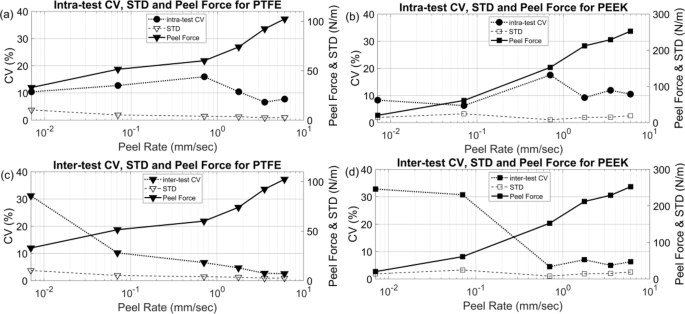

Peel testing is used to assess the bond quality and is a simple way of determining the adhesion strength of a material, especially in the case of a thin film deposited on a substrate By measuring the tension characteristics between the adhesive and the adherend surface, it is extremely useful in assessing the effects of processes (eg surface treatment, sterilisation) or reallife. TestResources peel testers or peel test machines, help determine the adhesive peel strength or the strength of the adhesive bond between two materials Our peel testers are optimized for peel testing applications The majority of peel tests are run at 250 to 300 mm/min (12 ipm) and performed with specially configured universal test machines. The Tpeel test is probably the most widely used peel test since it uses only one thickness of metal The Bell peel test is designed to peel at a constant radius around a 1in (252 cm) steel roll and, for this reason, provides more reproducible results ASTM D1781 uses a metaltometal climbing drum in an attempt to achieve this same constant.

The 90° peel test fixture consists of a bearingmounted sled that is linked to the testing machine’s crosshead by a cable and pulley system This fixture has a Tslotted sled that allows the substrate clamps, which secure the substrate to the sled, to adjust to a variety of substrate widths. Peel Testing Equipment Universal Test Machine Video Universal Test Machine Brochure Description This Peel Testing Equipment can do tensile test, tear test, peel test, bond test with different clamps for yarn,paper, tape, film,rubber and other kind of materials unversal test equipment uses the motor to drive screw to move fixtures Fix sample between upper and lower fixture and pull sample. Peel Strength of Metallic Clad Laminates 12/94 TM 2481 Peel Strength, Metal Foil (Keyhole Method for Thin Laminates) 01/86 TM 24A Peel Strength of Metallic Clad Laminates at Elevated Temperature (Hot Fluid Method) 12/94 TM 24A Peel Strength of Metallic Clad Laminates at Elevated Temperature (Hot Air Method) 12/94 TM 2484.

Abstract This test method details the standard procedures for the determination of the comparative peel or stripping strength characteristics of adhesive bonds when tested on standardsized specimens and under defined conditions of pretreatment, temperature, and testing machine speed. This test determines the peel strength of film lid of cooked rice package Custommade attachment is used to perform the 45 degree peel test, which is suitable for soft and rectangleshaped samples It is used for quality control and R&D. Peel Test n , Mandurah, Western Australia 154 likes · 1 talking about this We Test and electrical appliances and equipment Our professional team are all Nationally Accredited We comply.

ASTM F Peel Test System The ASTM F Peel Test System is a complete functional testing system from CSC Force Measurement that will provide full compatibility for the ASTM F testing standard for the most common testing methods, including the 90 degree supported and unsupported method (Technique A and Technique B). Reviews of Americas Test Kitchen Pizza Peel Here are top rated Pizza Peel consumer reports on the market today 1 – New Star Foodservice Aluminum Pizza Peel Check Price on Amazon Our top choice is New Star Foodservice Aluminum Pizza Peel offering the best of wood and aluminum This model features aluminum since it’s cost. Rather, another standard test method, ASTM D 3167, “Floating Roller Peel Resistance of Adhesives,” is commonly used to peel two solid sheets apart This test did not become an ASTM standard until 1973, but its method was developed earlier by Bell Aircraft and, at that time, was referred to as the Bell Peel test method.

Test Procedure Clamp each ends of the tpeel specimen in separate test grips of the universal tester / tension testing machine Separate the specimen at a rate of 127 mm (50 in) /min for (5in) length of the bond line Specimen size Specimens are cut from a Tpeel panel to 254 mm (10 in) long x 300 mm (12 in) wide Ten specimens are. 90/180 Degree Peel Test 90/180 Degree Peel Test is usually used control the adhesive characteristics as adhesion and tearing strength 90/180 Degree Peel Test is usually conducted on a Tensile Testing Machine with specifically grips There are some standards can be reference of 90/180 Degree Peel Test ASTM D3330, PSTC, etc. Learn about peel strength testing and the material testing solutions we provide for peel strength testing.

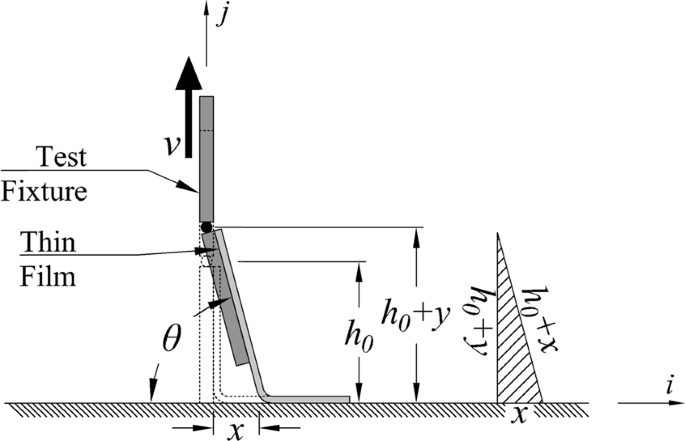

NIST Peel Test Procedure The NIST test was developed to quantitatively measure 90degree peel adhesion of coatings The test uses the peel test fixture, and a computerized universal testing machine (Fig 2) The testing machine provides a constant rate of peel and continuously measures the force of detachment during the test. The peel adhesion test is used to determine the force required to debond two components joined by an adhesive The test result, also known as bond strength, is generally represented as N (force to debond) / 25mm or 50mm (depending on specimen width). Accessories for the peel strenght test of the soldered cell with instructions for a correct procedure Both peel testers are adapt to be used by operators on the production line, granting a quick and easy use Manual peel tester for Ribbon Manual peel tester for EVA and Backsheet Category Testing equipment.

The “peel test” is a typical industry standard procedure that offers the opportunity to see under real conditions that the tape has been applied correctly According to the manufacturer, the adhesion should be cohesive (see photo 1) and should adhere to both the substrate and the pipe itself. Peel strength is a measure of the adhesive strength of two or more materials that have been bonded together A peel test is used to calculate the peel strength, which is then used to determine how effective an adhesive will be when joining certain types of materials. ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together This is commonly referred to as the “TPeel” test because the sample looks like the letter “T” when loaded in the machine before the test.

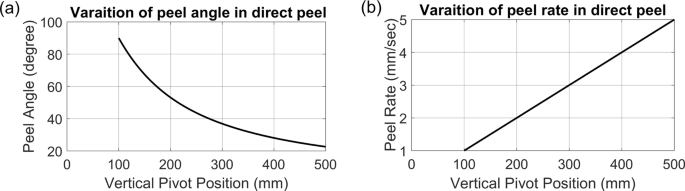

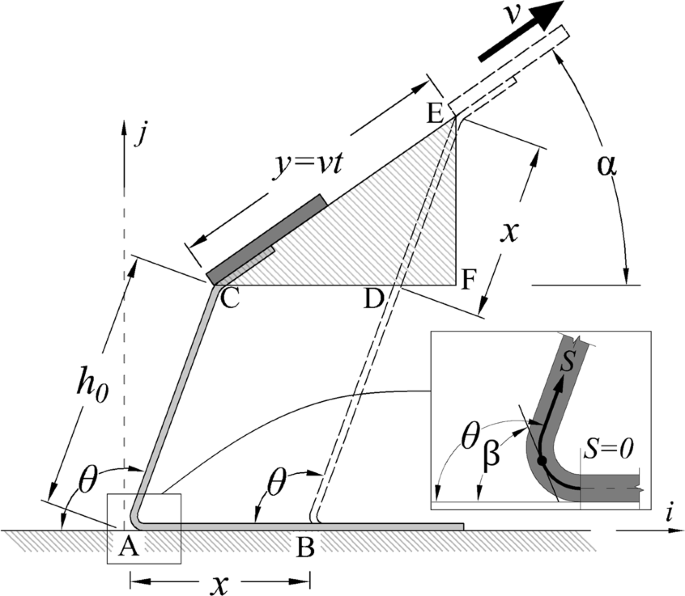

Peel strength(Peel adhesion strength,Bond test, Peel test )This indicator is directly related to the quality of the coating, the penetration of water and the tape and the adhesive force between the pipes, it should ensure a sufficient adhesion strength steel. Peel test is a simple mechanical test to measure the adhesion strength, especially for the case of a thin film deposited on a substrate Many experimental efforts and analyses have been devoted since the pioneer work of Strong in 1935, and a comprehensive survey on the earlier developments of the subject can be found in Kim and Aravas (19). Peel adhesion is the force required to remove a pressure sensitive adhesive from a testing plate or its own backing material The goal of a peel adhesion test is to determine the adhesive strength level of the material between two materials and is measured in ounces per one inch of tape.

Peel test is performed from a different angle such as 90 degree, 180 degree, etc Relation between Thickness of Adhesives and Peel Strength The thickness of adhesives plays a significant role that affects the peel strength of the adhesives It also depends on the properties of the adhesives With adhesives, the elastomeric behaviour and thick bond required a huge amount of force to peel the adhesives from the substrates. Peel tests are the most common test procedure performed on labels, tapes, coatings & other bonded materials There are different types of peel test such as 180degree peel test, 90degree peel test, etc 90 Degree Peel Test or 180degree peel test are commonly used where flexible materials such as adhesives and tapes.

Psm Polymer Service Gmbh Merseburg Fixed Arm Peel Test

Q Tbn And9gcqhhxqsdt4 Uzffpwjvlok6t3c2igzfbikwxjbv9pc Bf9ro5gd Usqp Cau

Peel Test An Overview Sciencedirect Topics

Peel Test のギャラリー

90 Degree Peel Tester Imada Inc

Schematic Diagram Of T Peel Test Download Scientific Diagram

Peel Adhesion Test 90 And 180 Peel Test Impact Solutions

Conduct Tape Adhesion Test Using Automated Test Machine

Tweezer Pull Ribbon Pull And Peel Xyztec English

Quantitative Peel Test For Thin Films Layers Based On A Coupled Parametric And Statistical Study Scientific Reports

Peel Testing Admet

90 Peel Off Tests Of Tissue Engineered Osteochondral Constructs A New Method To Determine The Osteochondral Integration

Peel Strength Testing

Peel Test An Overview Sciencedirect Topics

90 Degree Peel Unit Of Peel Test Fixtures Grips From Tinius Olsen

Quantitative Peel Test For Thin Films Layers Based On A Coupled Parametric And Statistical Study Scientific Reports

Schematic Of The Peel Test With Dimension Illustrations Of The Adhesive Download Scientific Diagram

Why Peel Adhesion Is Important

How To Perform An Adhesive Strength T Peel Test Astm D1876

Peel Test For Packaging Instron

Perform Peel Test To Determine The Strength Of Adhesives

Texture Analysis Professionals Blog Multiple Speed Peel Testing For The Assessment Of Adhesive Tapes

How To Do A Peel Adhesion Test In 3 Steps

Quantitative Peel Test For Thin Films Layers Based On A Coupled Parametric And Statistical Study Scientific Reports

Adhesives Design Toolkit

Test Data Products Dexerials

How To Perform Astm D903 Peel Or Stripping Strength Of Adhesive Bonds Massdevice

Tear Growth Peel And Adhesion Characteristics Of Films And Soft Elastic Foams

Variable Angle Peel Fixture

90 Degree Peel Test Fixture Gt 30 1

Peel Adhesion Tester Test Machine Equipment

90 Degree Peel Testing System Multiple Specimens Youtube

Astm B571 Metallic Coatings Peel Testing Machine 90 Degree Tensomax

Enhancing The Performance Of The T Peel Test For Thin And Flexible Adhered Laminates Review Of Scientific Instruments Vol 87 No 8

How To Do A Peel Adhesion Test In 3 Steps

1 Four Standard Peel Test Configurations A 90 Peel Test The Most Download Scientific Diagram

A Schematic Of The Peel Test Setup The Electrode Is Clamped On One Download Scientific Diagram

Peel Test Packaging Peel Strength Test At Campden Bri

Peel Testing Admet

Mechanics Of An Adhesive Tape In A Zero Degree Peel Test Effect Of Large Deformation And Material Nonlinearity Soft Matter Rsc Publishing

Roller Drum Peel Test Fixture Astm D3167 Wyoming Test Fixtures

.jpg)

Determine 180 Degree Peel Strength Of Adhesives

90 Degree Peel Tester Imada Inc

Peel Test

T Peel Tests For Adhesives

Q Tbn And9gcs0ogjddnt Xzpnfa2cniihbgsuqaqkehr9rxbshsn8qio Acxr Usqp Cau

Instron Peel Testing Of Screens Instron

Astm D1876 Adhesive T Peel Test

T Peel Test An Overview Sciencedirect Topics

Peel Adhesion Mecmesin Tv

90 180 Degree Peel Test Labthink

Astm D1876 Adhesive Peel Strength Testing Admet

Kit Research Ame Research Ame Peel Test

What Is 180 Peel Tensile Test

How To Do A Peel Adhesion Test In 3 Steps

Q Tbn And9gcrlu Gjus1 V 957qsxpxzz9ennkjjnfr6ony8wvgpr2pzjaahi Usqp Cau

Bol Com Modeling The Peel Test For Pressure Sensitive Adhesives Usa Zhang

Module Adhesion Embossed Character And Peel Tester Q Card

Enhancing The Performance Of The T Peel Test For Thin And Flexible Adhered Laminates Review Of Scientific Instruments Vol 87 No 8

Quantitative Peel Test For Thin Films Layers Based On A Coupled Parametric And Statistical Study Scientific Reports

Peel Mecmesin

How To Test The Peel Strength For Pipeline Anti Corrosion Tape

Peel Adhesion Mecmesin Tv

Mecmesin Solar Panel Peel Testing

Http Www Adhesivestoolkit Com Docu Data Npldocuments P a j Paj reports Paj3 reports Paj3 report 13 cmmt A 193 Pdf

Characterization And Failure Mode Analyses Of Air Plasma Oxidized Pdms Pdms Bonding By Peel Testing Rsc Advances Rsc Publishing

Q Tbn And9gcrlu Gjus1 V 957qsxpxzz9ennkjjnfr6ony8wvgpr2pzjaahi Usqp Cau

Adhesives Design Toolkit

Adhesives Design Toolkit

Adhesion Builds Over Time And Be Modified By Component Selection

Product Details Fgtt 12 90 Degree Peel Test Fixtures Accessories Options Force Gauges And Test Stands Products Digital Force Gauges Tension Meters Torque Meters Tachometers

Annayya Chandrashekar Gmail Com Peel Test

Annayya Chandrashekar Gmail Com June 18

A Numerical Analysis Of The Elastic Plastic Peel Test Sciencedirect

Peel Adhesion 90 Degree Testing Per Ftm 2

Yoghurt Bottle Peel Strength Testing

Peel Testing

Instron Peel Testing Of Screens Instron

45 Degree Peel Tester Imada Inc

6 5 2 Floating Roller Peel Test Leitfaden Kleben

Test Data Products Dexerials

Astm D3330 Test Method A 180 Peel Test On Single Coated Tape Mecmesin Force Measurement Youtube

Peel Adhesion Test 90 And 180 Peel Test Impact Solutions

Peel Testers Seal Strength Testing

Astm D1876 Instron

Peel Adhesion Test 90 And 180 Peel Test Impact Solutions

Peel Test Measurements For Au On Al A Schematic Of 90 Peel Test Download Scientific Diagram

Measurement Setup For T Peel Test Used To Determine The Adhesion Download Scientific Diagram

Enhancing The Performance Of The T Peel Test For Thin And Flexible Adhered Laminates Review Of Scientific Instruments Vol 87 No 8

Why Peel Adhesion Is Important

Enhancing The Performance Of The T Peel Test For Thin And Flexible Adhered Laminates Review Of Scientific Instruments Vol 87 No 8

Module Adhesion Embossed Character And Peel Tester Q Card

Tape Adhesive Peel Strength Test Use Kj 6001b Stainless Steel Panel Buy Stainless Steel Panel Film Testing Steel Peel Test Product On Alibaba Com

Test Method To Assess Interface Adhesion In Composite Bonding Springerlink

Gel Content Peel Test Pi Berlin

Rubber Adhesion Peel Test Youtube

How To Perform An Adhesive Strength T Peel Test Astm D1876 Youtube

What Is A Peeling Test

Peel Testing Admet

T Peel Test Geometry Download Scientific Diagram

Astm F Medical Package Testing

Instron Peel Testing Of Screens Instron

Psm Polymer Service Gmbh Merseburg T Peel Test

T Peel Tester Imada Inc

90 Degree Peel Test Fixture Gt 30 1