Drop On Demand Inkjet Printing

Drop on Demand inks Markem Imaje presents its range of DOD ink for drop on demand printing for the Crayon Plus, 40 and 5600 series.

![]()

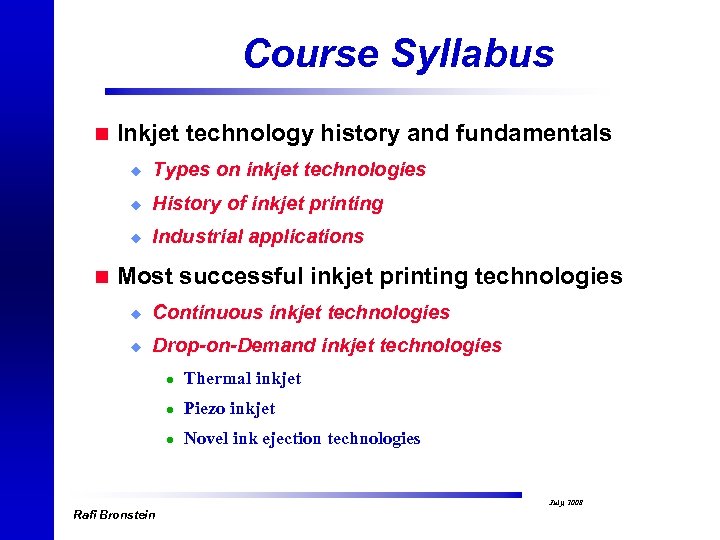

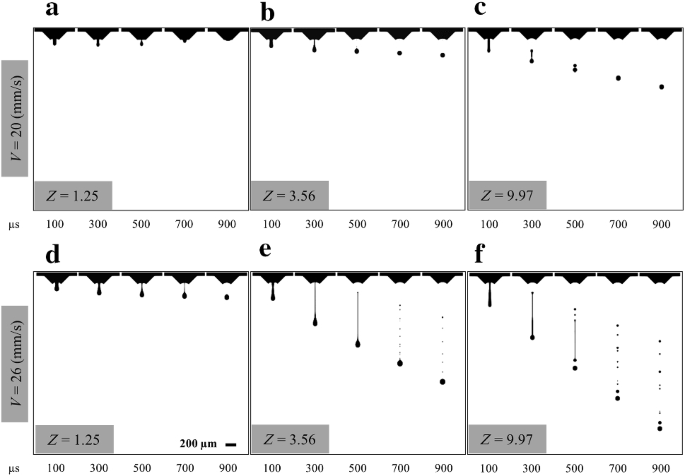

Drop on demand inkjet printing. Introduction This paper discusses the processes involved in the thinning of the ligaments of Newtonian liquids formed in dropondemand (DoD) inkjet printing, just before and including the final pinch off In particular the roles of the viscosity η and surface tension σ are examined. Micro Piezo technology is the backbone of every Epson inkjet printing system One of Epson's core technologies, Micro Piezo technology features Epson's unique Micro Piezo printheads combined with complementary technologies in image processing, ink systems, ink, media, and precision mechanisms such as paper feeders. KeywordsInkjet, dropondemand, SU8, selfassembled monolayer, functional materials Abstract This paper presents dropondemand inkjet printing of SU8 on functionalized surfaces for direct printing of computer controlled polymer patterns The high viscosity of SU8 required an indepth investigation of the print parameters such as pulse.

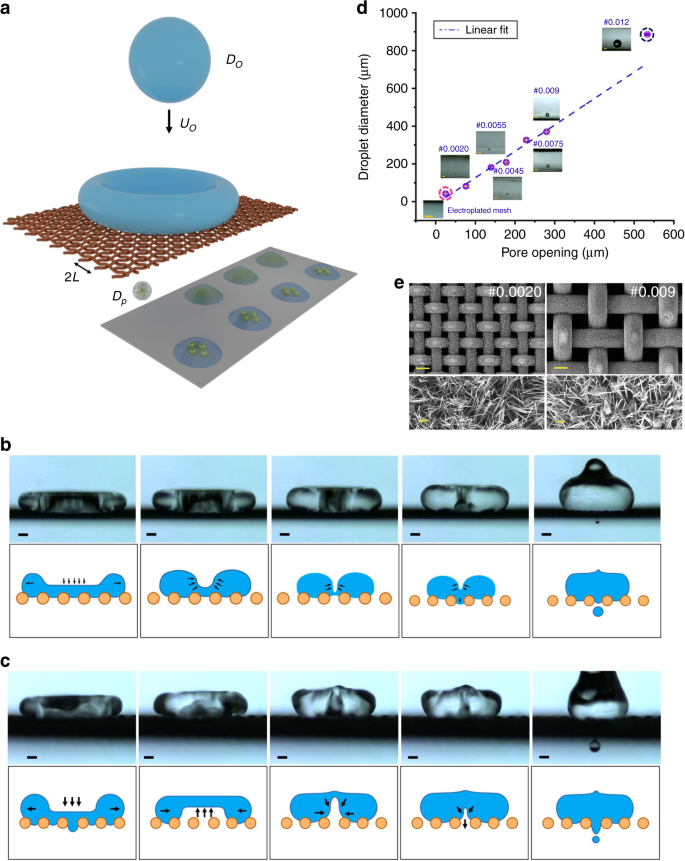

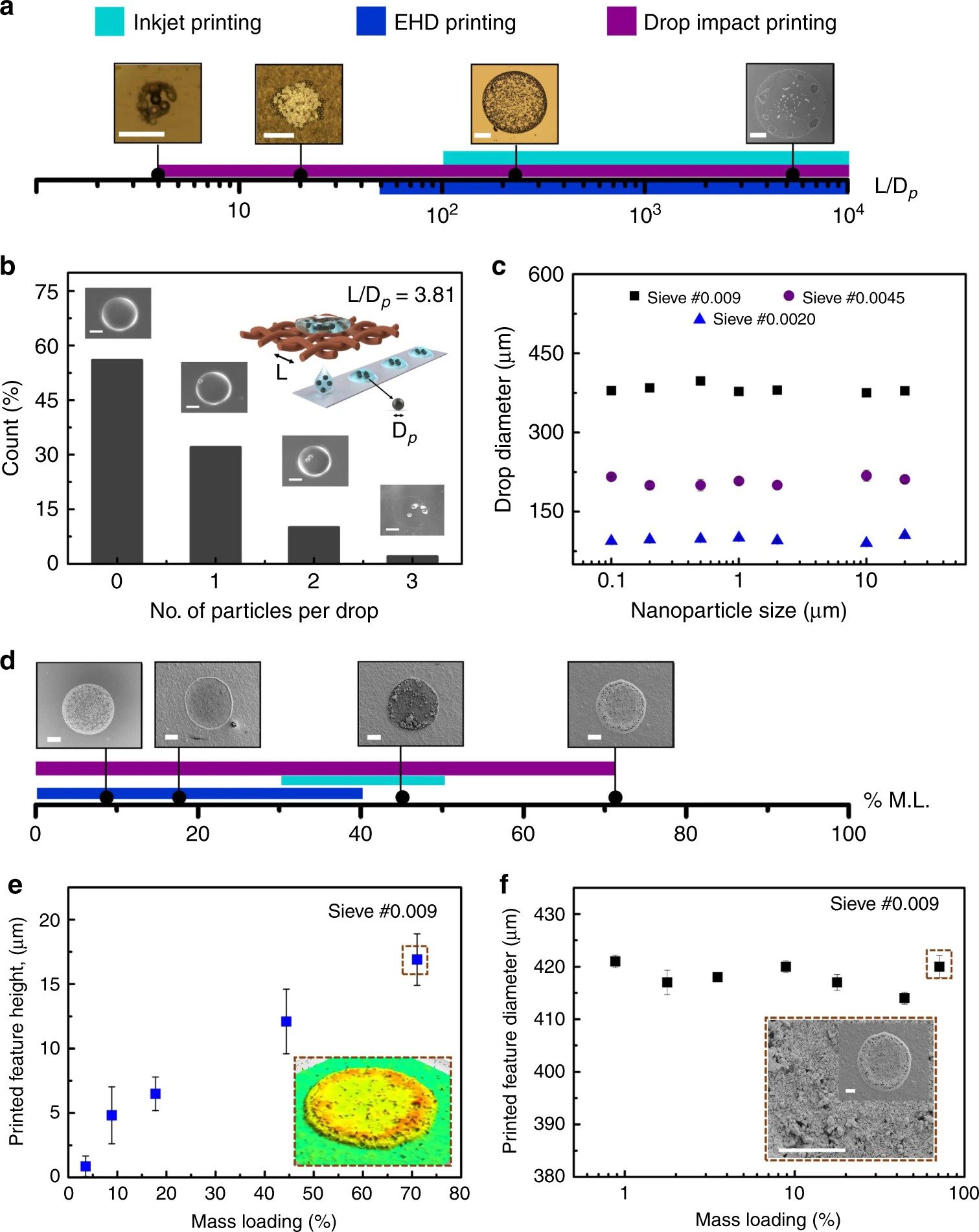

Researchers at the Center for Nano Science and Engineering (CeNSE), IISc, have developed a lowcost, dropondemand printing technique capable of generating a wide range of droplet sizes using a. KeywordsInkjet, dropondemand, SU8, selfassembled monolayer, functional materials Abstract This paper presents dropondemand inkjet printing of SU8 on functionalized surfaces for direct printing of computer controlled polymer patterns The high viscosity of SU8 required an indepth investigation of the print parameters such as pulse. Markoprint drop on demand inkjet printers Inkjet printers are a costeffective solution to fast and contactless marking of products and packaging Changing print text on a running conveyor?.

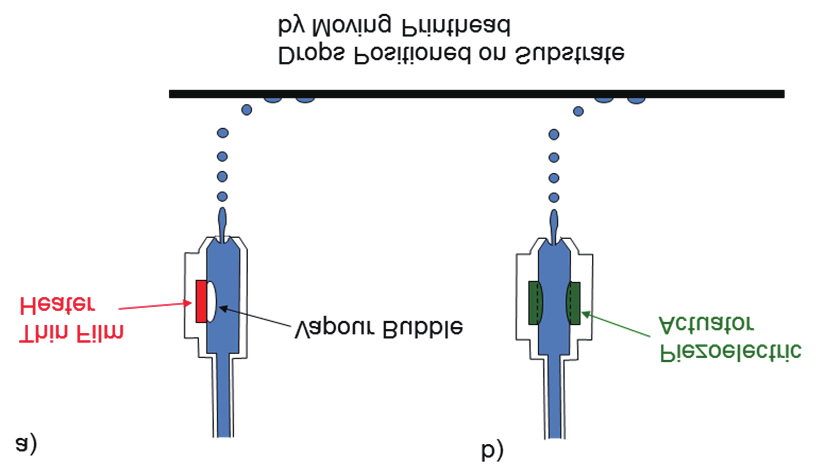

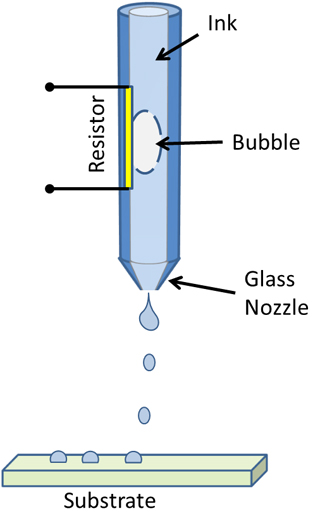

All desktop inkjet printers, and most wide format printers use dropondemand technology Inkjet printers can be used to print both images and documents Inkjet printers can print on a greater variety of papers than dye sublimation or electrophotographic, though care must be taken to match the right papers with the right inkjet printers. 22 Inkjet Printing Test materials were fabricated using a JetLab ® 4 (MicroFab Technologies, Plano, TX, USA) tabletop printing platform The system is shown in Figure 1(a)The JetLab ® 4 is a dropondemand inkjet printing system with drop ejection drive electronics (JetDrive™ III), a drop visualization system, and precision X, Y, Z motion control The standard manual pressure. Easy to use and operate (DOD) DroponDemand printers have been designed to out preform other prints on various applications.

Drop on demand printer technology Designed for use on porous substrates such as cardboard boxes, trays, and bags, our highresolution CSeries Plus range utilises piezo drop on demand (DOD) printing technology for consistent highquality results. Markoprint drop on demand inkjet printers Inkjet printers are a costeffective solution to fast and contactless marking of products and packaging Changing print text on a running conveyor?. Unlike CIJ (where a stream of drops of ink are constantly being formed and only deflected to the product when needed), TIJ is a drop on demand type of printer, each nozzle produces a drop of ink that is propelled to the substrate at the moment it is needed to build up the image.

Inkjet, or dropondemand printers use acoustic (ultrasound) or thermal energy to deposit drops of water containing cells in 2D space via moving the cartridge fixed on a linear rail, commonly with a moving stage to add dimensionality to the prints. Solidscape 3D printers for jewelry retailers, designers and professionals Your customers demand the best, and your designs deliver 3D printing, casting and production will, too With a Solidscape high resolution 3D printer in your shop, you’ll have the industry’s most detailed, dimensionally accurate 3D printed jewelry models at your fingertips 24/7. Printers with Drop on Demand (DOD) inkjet technology are expected to emerge as the fastestgrowing segment in 21 DOD inkjet printers are used in various industrial applications, such as printing on cardboard, plastics, timber and hardware, metals, packaging, and concrete products.

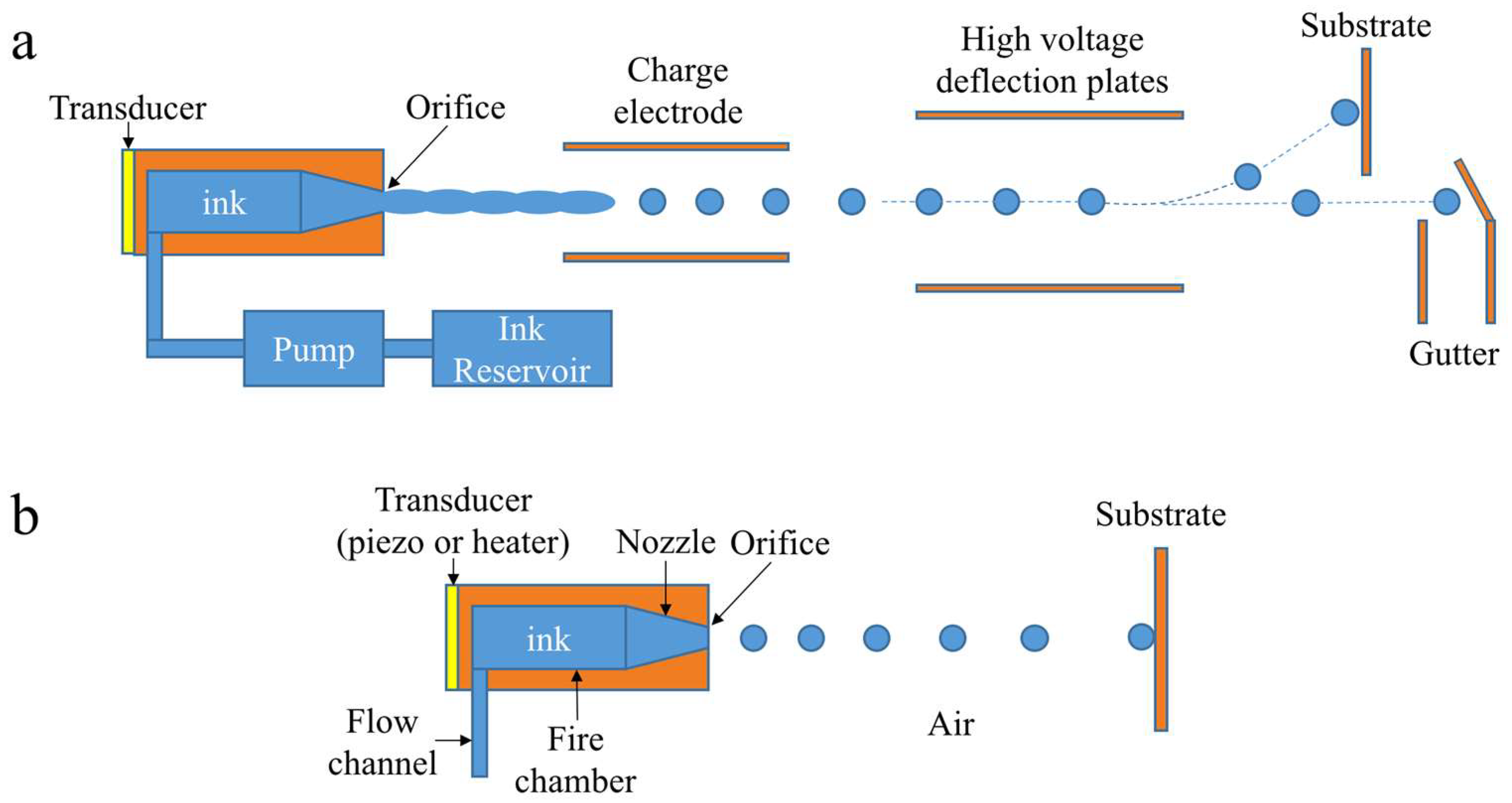

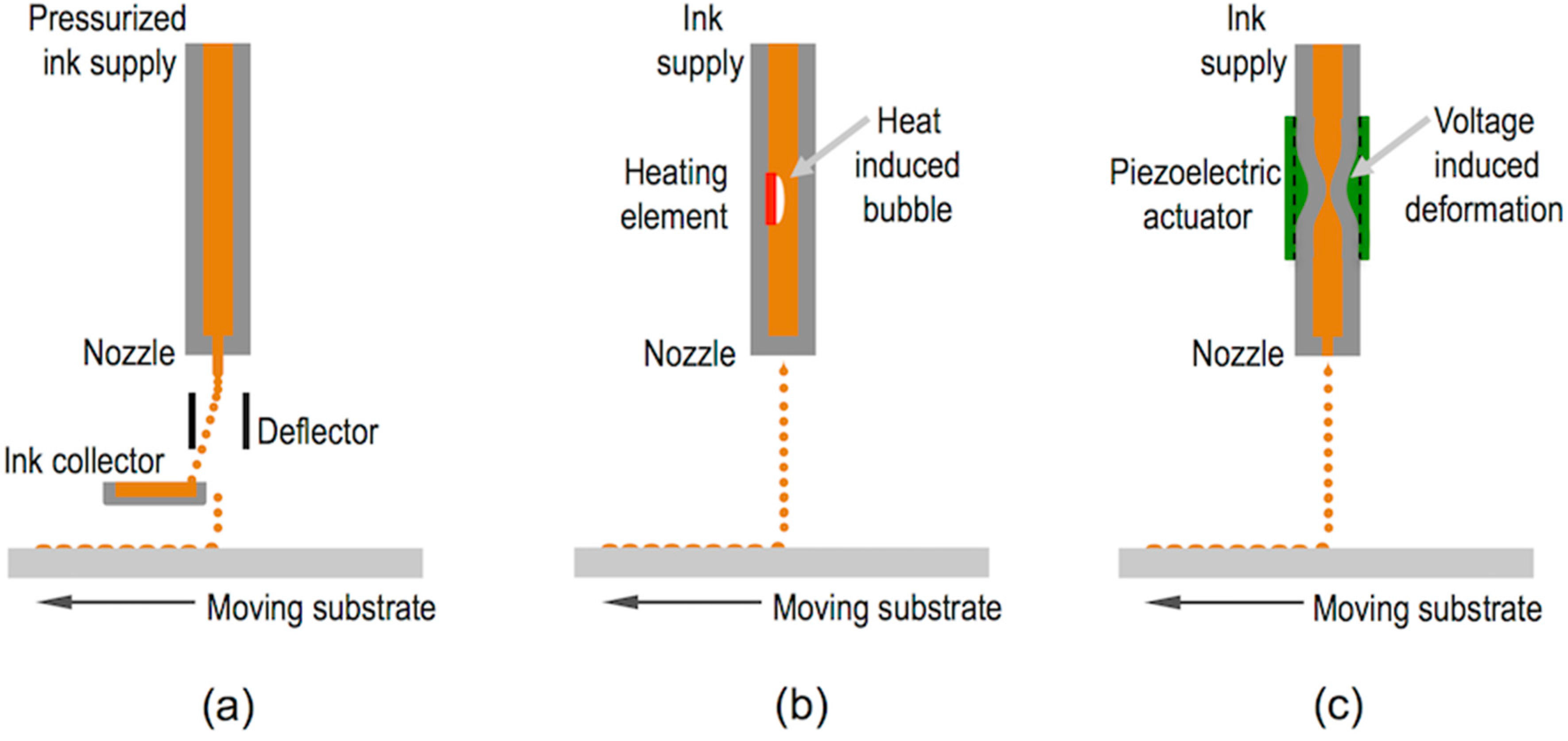

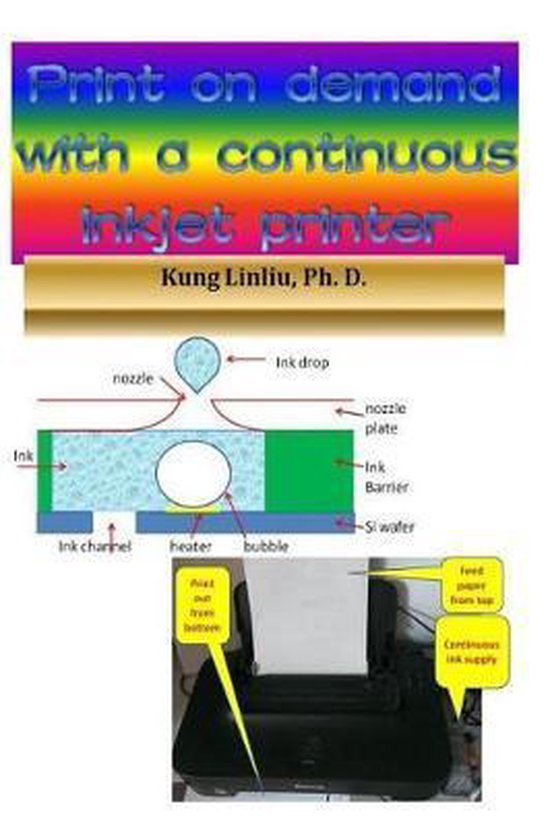

Dropondemand only produces and ejects droplets when required Continuous Inkjet Continuous inkjet is stigmatized in the printing industry as a primitive or amateur type of printing Continuous inkjet printers account for roughly 10% of the printer sales in North America in 16. 028”75”) and bold print DOD inkjet printers can be used across a broad array of industries for secondary printing (boxes, bags, cartons, boxes etc) and primary printing (steel beams, various. Dropondemand inkjet printers What are dropondemand systems?.

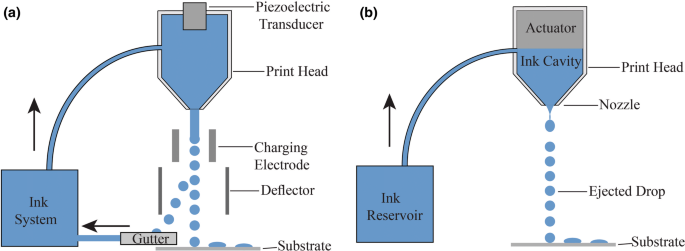

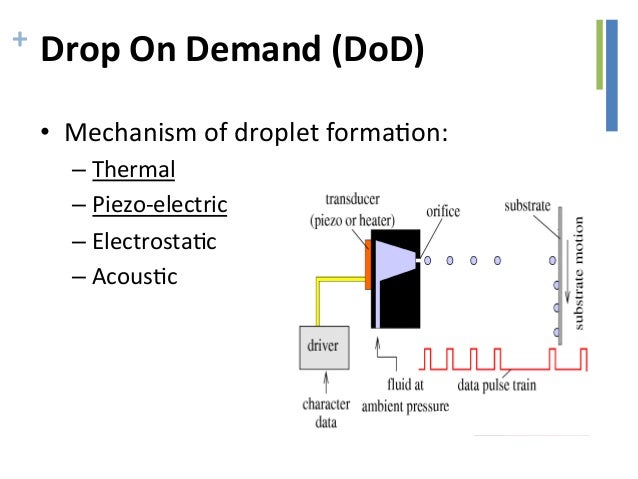

Dropondemand (DOD) In this method, drops of ink are released individually, on demand, by a voltage signal Released drops either fall vertically without any trajectory manipulation or require special fire timing when projected horizontally from a rotary printhead spinning at 121 RPM to form characters (Howtek color printer 1986). A Large Character DOD Inkjet Printer (Drop On Demand) is optimal for applications that require print heights greater than ½” (range 7mm190mm;. Dropondemand inkjet printing is a wellestablished method for commercial and consumer image reproduction The same principles that drive this technology can also be applied in the fields of functional printing and additive manufacturing Conventional inkjet technology has been used.

Dropondemand inkjet printing has proved efficient and reliable for direct markings on products and packaging But how does it work?. Printers with Drop on Demand (DOD) inkjet technology are expected to emerge as the fastestgrowing segment in 21 DOD inkjet printers are used in various industrial applications, such as printing on cardboard, plastics, timber and hardware, metals, packaging, and concrete products. With dropondemand inkjet printing, the printhead dispenses ink only when needed Dropondemand technology, when combined with variable drop sizes, permits greyscale printing, creating both photorealistic gradients and also vivid blacks, even on porous surfaces such as corrugated cardboard Continuous inkjet printing is an older technology.

14Drop on demand Drop on demand inkjet heads are now more affordable, with a lowcost ink system that is compact Typical drop volumes of individual ink drops are in the range of about 35–5 pL, producing printed spot sizes on paper in the range of 10– μm in diameter. 028”75”) and bold print. Drop on Demand (Large Character Ink Jet) Our line of Drop On Demand large character printers were designed for printing on a wide variety of substrates, including corrugated, plastics, metals, paper, foils, and more Their simple and robust design makes operation easy and reliable with a low cost of ownership compared to many other OEM’s Our printers are capable of printing multiple lines of text from a single printhead and can interface with a PC or PLC.

The MarketWatch News Department was not involved in the creation of this content Dec 06, (CDN Newswire via Comtex) Global Drop On Demand (DOD) Inkjet Printing Inks Market by. PrintJet is proud to Distribute Intermac DOD inkjet printers Our selection of Intermac DOD printers & markers have a number of excellent benefits and features Read more below!. For a particular printing ink and dropondemand piezoelectric inkjet printhead, piezoelectric voltage and temperature of the ink were varied to change the inkjet performance, and the jetting velocity of the inkjet was analyzed under various conditions The ink was cooled by using a Peltier module, which was attached to the nozzle plate as a.

Drop On Demand (DOD) Inkjet Printing Inks Market Dynamics Packaging is characterized by the aesthetics and primary product information indicated, along with a few other factors The quality of ink used for printing leads to the colors obtained, retention over the substrate, protection from splattering, the minimum time required to dry, and others. A dropondemand industrial printer may be the solution Our Foxjet VXseries line allows for multiple head printing configurations for character ranging from 1/2" to 2" in size Water or solventbased printers for porous and nonporous surfaces Option of running 1 or 2 printing heads. About Independent Ink Independent Ink Inc was established in 1939 as a custom formulator of government and military specification inks and solvents In 1980 a major US bottler asked us to develop jet printing and makeup inks specifically formulated to work with continuous ink jet (CIJ) and drop on demand (DOD) printing equipment.

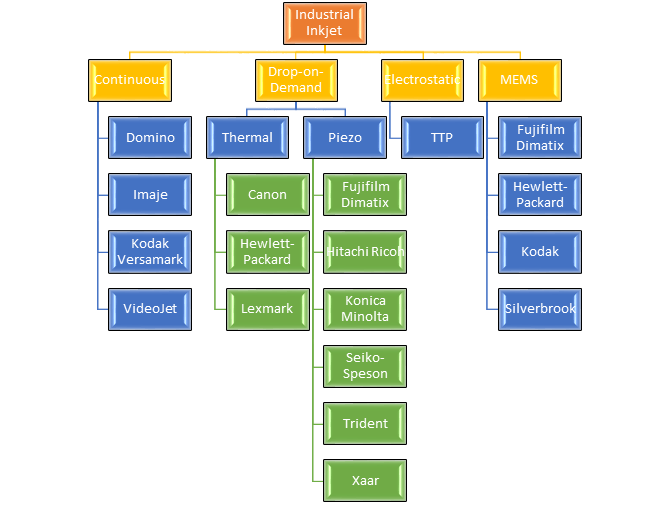

In this letter, the authors demonstrate Drop‐on‐Demand printing of variable focus, polarization‐independent, liquid crystal (LC) microlenses By carefully selecting the surface treatment applied to a glass substrate, the authors are able to deposit droplets with a well‐defined curvature and contact angle, which result in micron‐sized lenses with focal lengths on the order of 300–900 µm. Drop On Demand (DOD) Inkjet Printing Inks market is split by Type and Application For the period 1525, the growth among segments provide accurate calculations and forecasts for sales by Type and Application in terms of volume and value This analysis can help you expand your business by targeting qualified niche markets. Dropondemand inkjet DOD inkjet is by far the most common and broadest classification of inkjet printing This is most commonly used by companies such as HewlettPackard, Fujifilm, Lexmark, and Canon.

Drop On Demand (DOD) Inkjet Printing Inks research report has combined the analysis of different aspects that increase the market's growth It constitutes trends, restraints, and drivers that. In this paper, a dropondemand (DOD) inkjet experimental system is established A numerical model is developed to investigate the influence of the operating conditions on droplet stability, including nozzle dimensions, driving parameters (the pulse amplitude and width used to drive droplet formation) and fluid properties. In dropondemand printers, over and underpressure waves ensure that individual drops of ink emerge from a cartridge as needed The required print image is subsequently composed of these individual ink droplets.

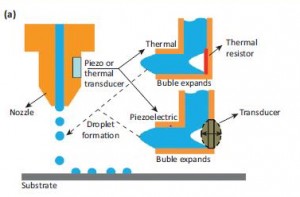

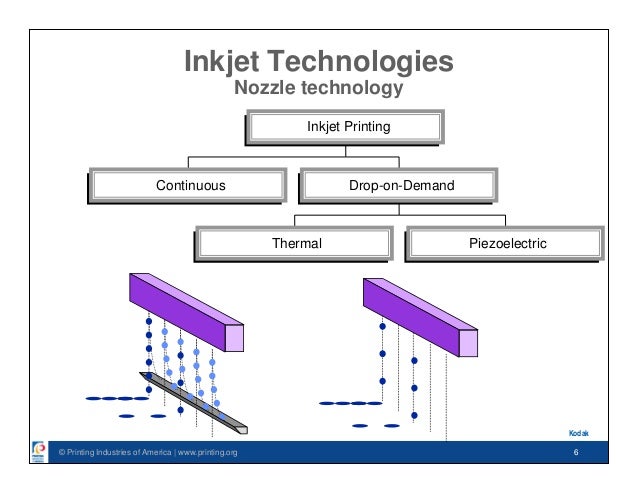

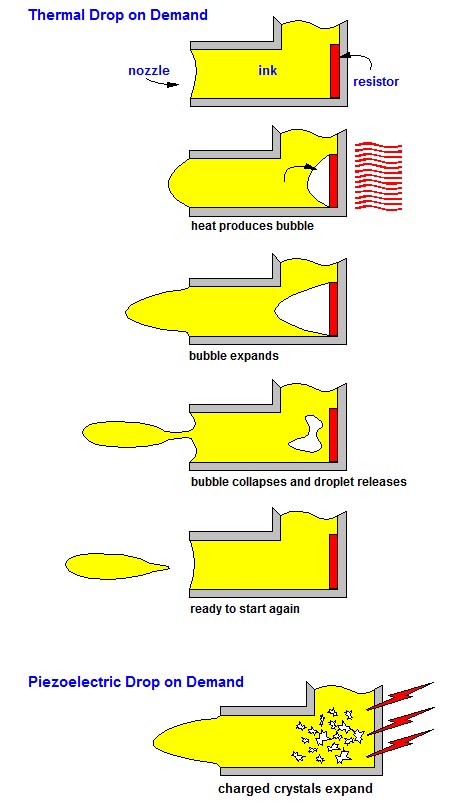

A dropondemand industrial printer may be the solution Our Foxjet VXseries line allows for multiple head printing configurations for character ranging from 1/2" to 2" in size Water or solventbased printers for porous and nonporous surfaces. Inkjet printers provide the unique solution for the photographers with the ability to print on any substrate Global Inkjet Printing Technologies market is segregated on the basis of technology type as continuous inkjet, and drop on demand. The majority of activity in inkjet printing today is in the dropondemand methods Depending on the mechanism used in the drop formation process, the technology can be categorized into four major methods thermal, piezoelectric, electrostatic, and acoustic inkjet.

Markoprint drop on demand inkjet printers Inkjet printers are a costeffective solution to fast and contactless marking of products and packaging Changing print text on a running conveyor?. Drop on demand printer technology Designed for use on porous substrates such as cardboard boxes, trays, and bags, our highresolution CSeries Plus range utilises piezo drop on demand (DOD) printing technology for consistent highquality results Acknowledged as one of the fastest 70mm highresolution printer on the market, the CSeries Plus piezo printer also has the large ink capacity, a wide variety of print head options, and the low power consumption for highresolution printing. Drop On Demand (DOD) Inkjet Printing Inks market is split by Type and Application For the period 1525, the growth among segments provide accurate calculations and forecasts for sales by Type and Application in terms of volume and value This analysis can help you expand your business by targeting qualified niche markets.

The group proposed a new method, so called dropondemand printing, as a method to achieve optimal (re)lubrication with a minimum lubricant quantity in a single ball contact The researchers applied the inkjet printing technology to develop their new method. Dropondemand Inkjet Printing Technology We offer modern dropondemand inkjet printing technology perfectly reflected in a special line of our products We designed these products for a complete range of applications implementing the latest DOD technology and printing standards in line with modern demands Our DOD inkjet printer Famjet Makro is designed for marking any material and a variety of types of substrates such as pipes, bags insulation sleeves, fabrics, extruded packing, using. The DOD inkjet printing process for initial batches of platinum organometallic Printing process consists of five stages, which are drop inks DroponDemand (DOD) inkjet printing works by ejection, drop flight, drop impact, drop spreading and drop inducing a transient pressure pulse in the ink reservoir through evaporation5.

Q 1What is your main products of ink?. Inkjet printing (IJP) is a wellknown dropondemand technology for depositing tiny droplets onto substrate without dependence on the highspeed operation of mechanical printing elements Figure 1126 gives a comparison of the hand painting process and the IJP method Nozzle sizes for the printers are usually –30 μm with ink droplets as small as 15 pL. Our inkjet printers distinguish themselves from other labeling systems through exceptionally high efficiency and innovative features.

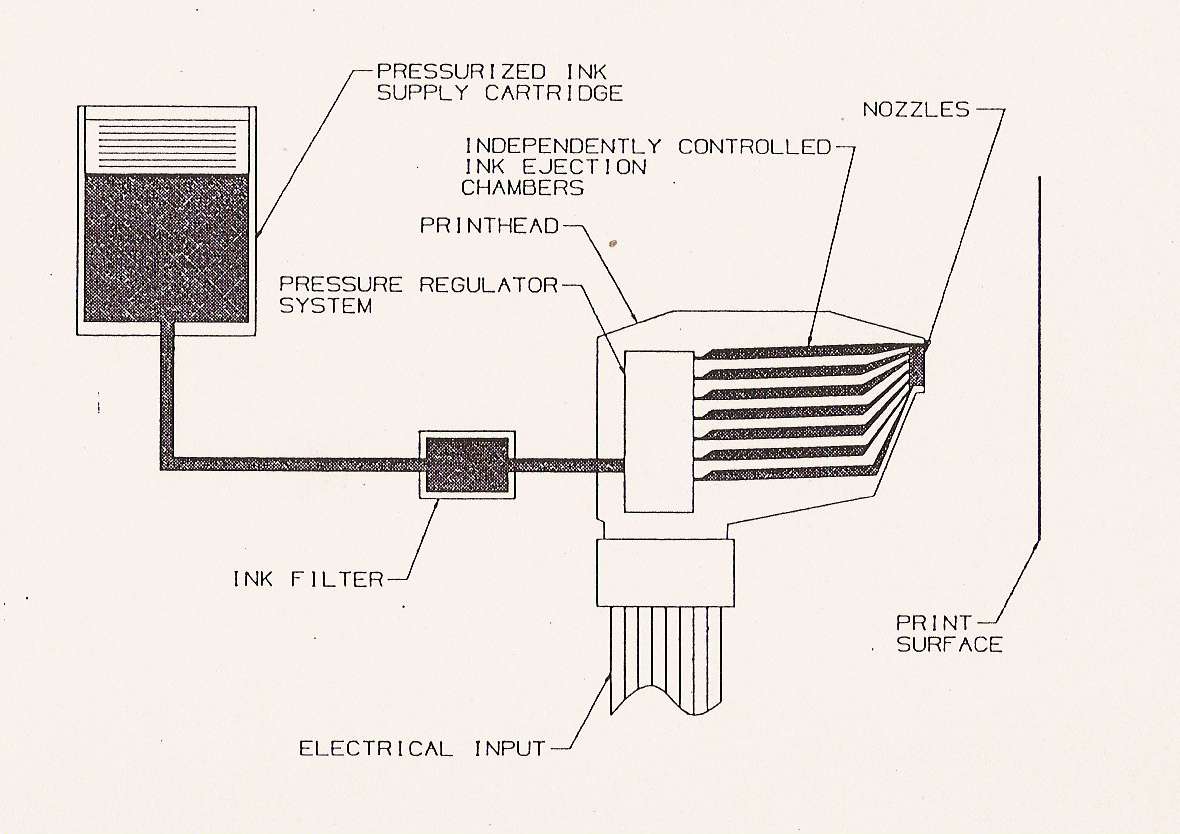

Printers with Drop on Demand (DOD) inkjet technology are expected to emerge as the fastestgrowing segment in 21 DOD inkjet printers are used in various industrial applications, such as printing on cardboard, plastics, timber and hardware, metals, packaging, and concrete products. Printers with Drop on Demand (DOD) inkjet technology are expected to emerge as the fastestgrowing segment in 21 DOD inkjet printers are used in various industrial applications, such as printing on cardboard, plastics, timber and hardware, metals, packaging, and concrete products. Inkjet Printer Product Lines •Solutions evolved from desktop into business and industrial applications HP Thinkjet 1 page per second •Modular, expandable systems •Precision dispense •Drop on demand •Multiple fluids •High flux capacities First Inkjet Product, 1984.

REA JET inkjet printers are the leading choice for printing and coding on industrial products Designed for challenging applications like printing on metal, plastic, and rubber, REA JET large and small character inkjet coders offer excellent printing performance and low maintenance for maximum production uptime. When it comes to inkjet printers, there are two kinds Continuous and DroponDemand, and in this article we’ll look at both and their differences Read on to find out more Continuous Inkjet (CIJ) This method of inkjet printing relies on a method of providing a continuous flow of ink during the printing process. Easy to use and operate (DOD) DroponDemand printers have been designed to out preform other prints on various applications Large LP7000 plus inkjet controller with graphic LCD display with Easy to Use Software Menus Provides flexible marking with fast speeds of 175 meters per minute.

ACheef ink manufactures a full line of high quality, low cost alternative inks, makeup, and cleaners for Continuous Ink Jet (CIJ), Drop on Demand (DOD) and HighResolution industrial printers and coders Innovative technology is the core of our business, and our inks are trusted alternatives to products from many OEMs including Videojet, Domino, Imaje. A Large Character DOD Inkjet Printer (Drop On Demand) is optimal for applications that require print heights greater than ½” (range 7mm190mm;. For the best in versatility, reliability, quality and cost efficiency, consider a drop on demand inkjet printer from PrintJet Corporation Our industry leading drop on demand (DOD) printers and carton printers are wellsuited for carton printing that requires large character coding Drop on demand printers deliver great results on porous material such as secondary packaging, corrugated boxes, and wood, as well as nonporous materials such as metal and plastic or cartons with varnish.

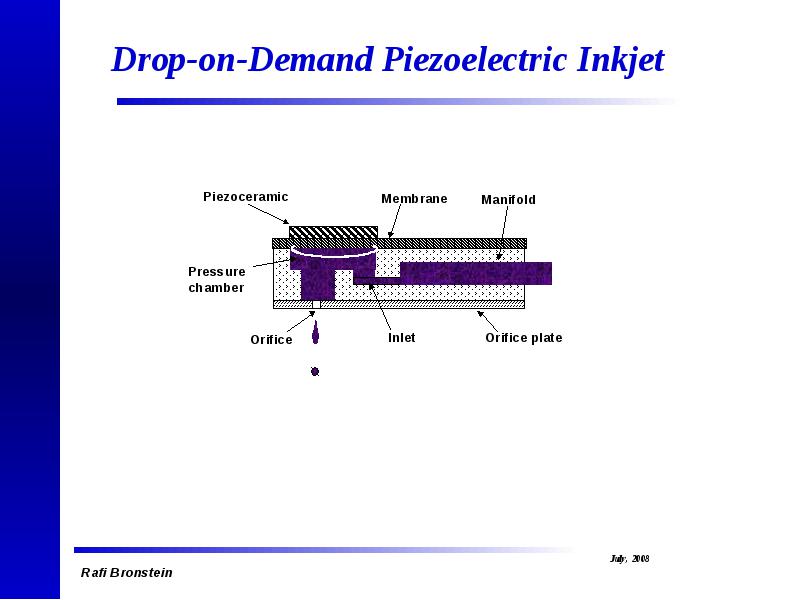

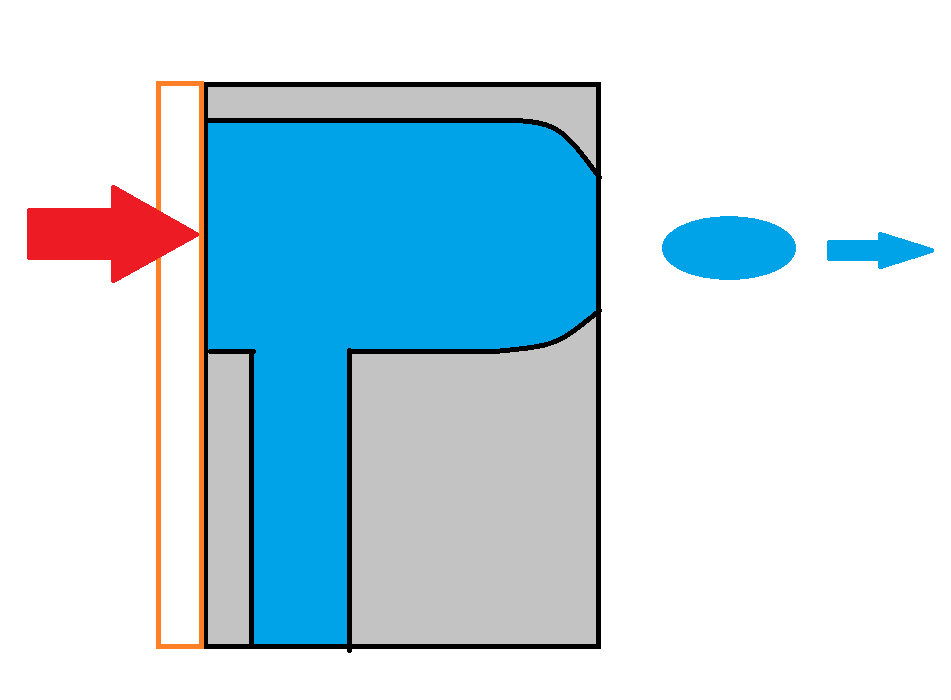

There are several approaches to designing printheads but by far the most common for wideformat inkjet is dropondemand piezo Essentially the printhead contains an ink chamber, with a piezo electric actuator, made of a material such as Lead Zirconium Titanium (PZT). Printers with Drop on Demand (DOD) inkjet technology are expected to emerge as the fastestgrowing segment in 21 DOD inkjet printers are used in various industrial applications, such as printing on cardboard, plastics, timber and hardware, metals, packaging, and concrete products. This paper presents dropondemand inkjet printing of SU8 on functionalized surfaces for direct printing of computer controlled polymer patterns The high viscosity of SU8 required an indepth investigation of the print parameters such as pulse amplitude, pulse length and temperature in the piezoactuated nozzle.

In dropondemand inkjet printers, the printing heads eject discontinuous droplets onto the printing substrate to produce the image by means of the heatinduced explosion of ink bubbles (eg in bubble jet printers and thermal inkjets) Principle In the dropondemand technique, the ink in the tiny print cartridge chambers is. This study describes a novel method for singlecell analysis and lipid profiling by combining dropondemand inkjet cell printing and probe electrospray ionization mass spectrometry (PESIMS) Through inkjet sampling of a cell suspension, droplets with single cells were generated, precisely dripped onto a tungstenmade electrospray ionization needle, and immediately sprayed under a highvoltage electric field.

How Does Drop On Demand Dod Inkjet Printing Work

Schematic Showing The Drop On Demand Inkjet Printing System Used In The Download Scientific Diagram

Progress And Trends In Ink Jet Printing Technology

Drop On Demand Inkjet Printing のギャラリー

0dpi Van De Drukmachines Van Dalings Het Industriele Inkjet Online Type Op Bestelling

Inkjet Printing For Biosensor Fabrication Combining Chemistry And Technology For Advanced Manufacturing Lab On A Chip Rsc Publishing

The U S Computer Printer Industry

Study Of Pinch Off Locations During Drop On Demand Inkjet Printing Of Viscoelastic Alginate Solutions Langmuir X Mol

Fluids Free Full Text One Dimensional Model For Droplet Ejection Process In Inkjet Devices Html

The Role Of Concentration On Drop Formation And Breakup Of Collagen Fibrinogen And Thrombin Solutions During Inkjet Bioprinting Biorxiv

Industrial Dod Drop On Demand Inkjet Printing Printer China Manufacturer

Ris Utwente Nl Ws Files Thesis M Van Der Meulen Pdf

Inkjet Printing Inkjet Technology Fundamentals Rafi Bronstein Rafi

Bioprinting Inkjet Deposition Saunders Major Reference Works Wiley Online Library

Additive Manufacture Of Ceramics Components By Inkjet Printing

Types Of Thermal Drop On Demand In Inkjet Printing Technology A Roof Download Scientific Diagram

Drop On Demand Inkjets An Overview Sciencedirect Topics

.png)

Inkjet Printer Commercial Printer 3d Printer Bio Material Dispensing Single Pass Printing And Ceramic Ink Printer Pump

Inkjet Technology And Inkjet Printing Rafi Bronstein

Inkjet Technology A Continuous Inkjet Printing B Drop On Demand Download Scientific Diagram

Inkjet Printing Wikipedia

Introduction To Industrial Inkjet Printing Imi Europe High Quality Inkjet Conferences And Courses

주 유니젯

About Printing The University Of Manchester Science And Engineering

Micro And Bio Rapid Prototyping Using Drop On Demand 3d Printing Springerlink

Drop Impact Printing Nature Communications

Design And Fabrication Of A Piezoelectric Bend Mode Drop On Demand Inkjet Printhead With Interchangeable Nozzle Scientific Net

2

Design And Implement Of A Low Cost Drop On Demand Inkjet Printing System Scientific Net

Accessing Individual 75 Micron Diameter Nozzles Of A Desktop Inkjet Printer To Dispense Picoliter Droplets On Demand Rsc Advances Rsc Publishing

I Dot Immediate Drop On Demand Technology Youtube

Minimal Quantity Lubrication Drop On Demand Printing Technique Tribology Tribonet

Researchers Mitigate Drop On Demand 3d Printing Drawbacks With Superhydrophobic Sieve 3d Printing Industry

Perovskite And Organic Solar Cells Fabricated By Inkjet Printing Progress And Prospects Peng 17 Advanced Functional Materials Wiley Online Library

Printing Mechanisms Inkfinite

Inkjet Is Inkjet Right All Printing Resources

Pdf Electrostatic Induced Inkjet Printing System For Micro Patterning And Drop On Demand Jetting Characteristics Semantic Scholar

Effects Of The Actuation Waveform On The Drop Size Reduction In Drop On Demand Inkjet Printing Springerlink

A Schematic Diagram Of A Continuous Inkjet Cij Printer Left And A Download Scientific Diagram

Pdf Pattern Characteristic By Electrostatic Drop On Demand Ink Jet Printing Using Capillary Inkjet Head System Semantic Scholar

Http Iopscience Iop Org Article 10 10 0960 1317 22 7 Pdf

Precise Ink Supply For Best Print Quality

Pdf Experimental Temperature Compensation On Drop On Demand Inkjet Printing Semantic Scholar

Ub Chemical And Biological Engineering

Inkjet Technology And Inkjet Printing Rafi Bronstein

Mas 865 18 How To Make Something That Makes Almost Anything

Cordis Europa Eu Docs Projects Cnect 8 3180 080 Deliverables 001 D1111demonstrationofsinglepassinkjetprintingsystem Pdf

16 Schematic Representation Of The Drop On Demand Inkjet Printing Download Scientific Diagram

China New Arrival Large Format Textile Inkjet Printer With Dx5 Dx7 Drop On Demand Micro Piezo Print Heads China Textile Printer Digital Textile Printer

Inkjet Printing For Biosensor Fabrication Combining Chemistry And Technology For Advanced Manufacturing Lab On A Chip Rsc Publishing

Inkjet Printing Basics Cij Vs Dod Publishing And Printing

Drop On Demand Inkjet Printing A Thermal B Piezoelectric C Download Scientific Diagram

Mems Contributes To The Inkjet Printing Industry R Evolution

Inkjet Printing Basics Cij Vs Dod Publishing And Printing

Drop On Demand Dod Inkjet Printer 7 Dots Large Character Inkjet Coding Machines

Additive Manufacture Of Ceramics Components By Inkjet Printing Sciencedirect

Q Tbn And9gct8 Gpeluj8 Xdfakzwz5czfhs2wbyf4anix6nxw7pnmpekb5u2 Usqp Cau

Materials Free Full Text Inkjet Printing Of Functional Materials For Optical And Photonic Applications Html

The Simulation Study Of Fluid Physical Properties On Drop Formation Of Drop On Demand Inkjet Printing Topic Of Research Paper In Nano Technology Download Scholarly Article Pdf And Read For Free On Cyberleninka Open

Djm Home

3d Printed Electronics Of Non Contact Ink Writing Techniques Status And Promise Springerlink

Inkjet Technology Wikipedia

Drop On Demand Inkjets An Overview Sciencedirect Topics

Trend Alert The Evolving Role Of Production Inkjet

Chapter 2 Fundamentals Of Inkjet Technology Inkjet Technology For Digital Fabrication Book

Inkjet Printing Process For Kesterite Solar Cells

Dp3 Digital Print Preservation Portal Inkjet

2

Drop On Demand Printing Of Conductive Ink By Electrostatic Field Induced Inkjet Head Applied Physics Letters Vol 93 No 19

15 11 11 Inkjet Printing Part1

Other Drop On Demand Inkjet Printers A Electrostatic Inkjet Printer Download Scientific Diagram

Bol Com Print On Demand Pod With A Continuous Inkjet Printer Kung Linliu

Additive Manufacture Of Ceramics Components By Inkjet Printing Sciencedirect

Piezo Print Heads Vs Thermal Print Heads Edge Colours

Progress And Trends In Ink Jet Printing Technology

Drop On Demand Inkjet Printer Printing Systems Dod

11 3 Efficiency Cu In Ga S Se 2 Thin Film Solar Cells Via Drop On Demand Inkjet Printing Energy Environmental Science Rsc Publishing

Oem Pumps For Inkjet Printing Systems Thomas

Kopen Drop On Demand Inkjet Printer Van Goede Kwaliteit Drop On Demand Inkjet Printer Fabrikant

Experimental Study Of The Parameters For Stable Drop On Demand Inkjet Performance Physics Of Fluids Vol 31 No 3

Inkjet Printing As A Key Enabling Technology For Printed Electronics Sigma Aldrich

Q Tbn And9gcr3npinju7v0fbbak Nemwtwi8amcc Upms2luthx2lj57fknnq Usqp Cau

Predicting Inkjet Dot Spreading And Print Through From Liquid Penetration And Picoliter Contact Angle Measurement In Nordic Pulp Paper Research Journal Volume 35 Issue 1

Other Drop On Demand Inkjet Printers A Electrostatic Inkjet Printer Download Scientific Diagram

Www Globalinkjetsystems Com Wp Content Uploads Inkjet Printhead Technology Overview Pdf

What You Should Know About Inkjet Technology Edge Colours

Nanyang Technological University Inkjet Printing Of Zno Micro Sized Thin Films 3dprint Com The Voice Of 3d Printing Additive Manufacturing

3

Development And Characterization Of A Drop On Demand Inkjet Printing System For Nuclear Target Fabrication Sciencedirect

Micro And Bio Rapid Prototyping Using Drop On Demand 3d Printing Springerlink

Drop On Demand Inkjet Printing Of Su 8 Polymer Bentham Science

Supply Various Industrial Inkjet Printer Industrial Inkjet Coder Handheld Inkjet Coder Of High Quality

Bank Card Personalisation Ruhlamat

2

How Does Drop On Demand Dod Inkjet Printing Work

Acoustophoretic Printing Science Advances

Jet Break Up In Drop On Demand Inkjet Printing Evangelia Antonopoulou Youtube

S3 Eu West 1 Amazonaws Com Itempdfprod Inkjet Printed Mesoporous Tio2 And Perovskite Layers For High Efficiency Perovskite Solar Cells V1 Pdf

Inkjet Printing Article About Inkjet Printing By The Free Dictionary

주 유니젯

Recent Advances And Prospects Of Inkjet Printing In Heterogeneous Catalysis Catalysis Science Technology Rsc Publishing Doi 10 1039 D0cyj

Figure 26 From Toward Better Printing Quality For A Drop On Demand Ink Jet Printer Improving Performance By Minimizing Variations In Drop Properties Semantic Scholar

Operating Principle Of A Drop On Demand Inkjet Printing System Download Scientific Diagram

Inkjet Printing Wikipedia